Preparation method of low-VOC polypropylene resin and polypropylene resin prepared by method

A technology of polypropylene resin and polypropylene, which is applied in the field of polypropylene resin, can solve problems such as compatibility and durability, and achieve the effects of good thermal stability, delayed release, and suppression of VOC production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

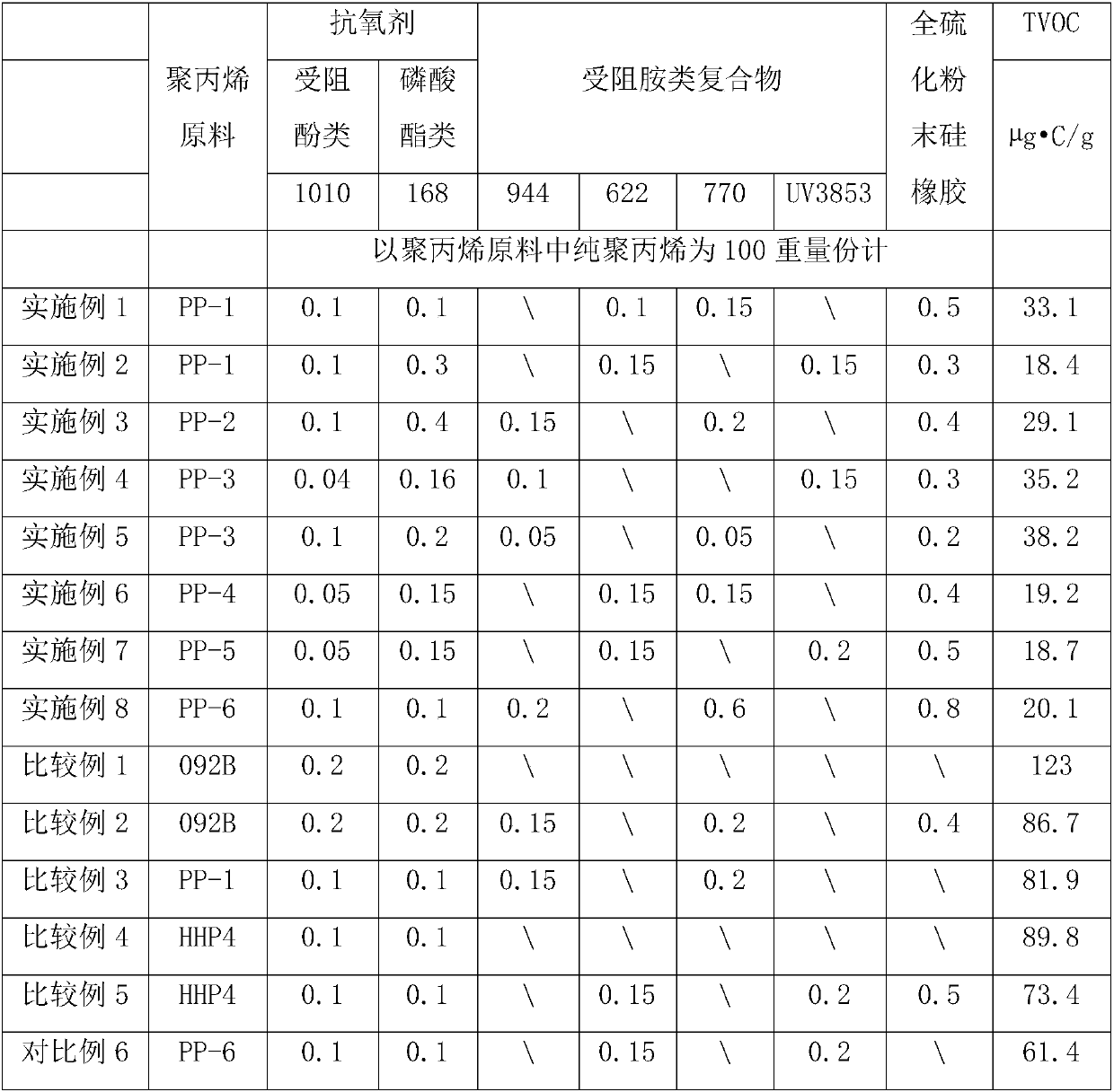

Examples

Embodiment 1~3

[0033] Soak polypropylene powder (092B, Beijing Research Institute of Chemical Industry) in n-hexane solvent at 30-60°C for 8-72 hours, filter the solution, then dry the polypropylene powder and a small amount of solvent in a vacuum oven at 80°C Obtain dry polypropylene powder in 4 hours (the processing conditions of polypropylene powder are 50°C and 36h, which are recorded as PP-1; 30°C and 72h are recorded as PP-2; 60°C and 8h are recorded as PP-3;); Afterwards, the treated polypropylene powder, fully vulcanized powder silicone rubber (VP-602, particle size 0.1 μm, gel content 90%, Beijing Research Institute of Chemical Industry), antioxidant (antioxidant 1010 and antioxidant 168 It is obtained by compounding at a weight ratio of 1: (1 to 4), BASF in Germany), light stabilizer (BASF in Germany or Cytec in the United States) into a high-speed mixer, and stirred at a speed of 300 rpm for 3 Minutes to fully mix the components uniformly; then pass the above-mentioned mixed mater...

Embodiment 4

[0036] Soak polypropylene powder (092B, Beijing Research Institute of Chemical Industry) in n-hexane solvent at 30-60°C for 8-72 hours, filter the solution, then dry the polypropylene powder and a small amount of solvent in a vacuum oven at 80°C Obtain dry polypropylene powder in 4 hours (the processing conditions of polypropylene powder are 50°C and 36h, which are recorded as PP-1; 30°C and 72h are recorded as PP-2; 60°C and 8h are recorded as PP-3;); Afterwards, the treated polypropylene powder, fully vulcanized powder silicone rubber (VP-602, particle size 0.05 μm, gel content 75%, Beijing Research Institute of Chemical Industry), antioxidant (antioxidant 1010 and antioxidant 168 It is obtained by compounding at a weight ratio of 1: (1 to 4), BASF in Germany), light stabilizer (BASF in Germany or Cytec in the United States) into a high-speed mixer, and stirred at a speed of 300 rpm for 3 Minutes to fully mix the components uniformly; then pass the above-mentioned mixed mate...

Embodiment 5

[0039] Soak polypropylene powder (092B, Beijing Research Institute of Chemical Industry) in n-heptane solvent at 30-60°C for 8-72 hours, filter the solution, then put polypropylene powder and a small amount of residual solvent in a vacuum oven at 80°C Dried for 4 hours to obtain dry polypropylene powder (the processing conditions of polypropylene powder are 50°C and 36h, which is marked as PP-1; 30°C and 72h, marked as PP-2; 60°C and 8h, marked as PP-3;) ; Afterwards, the processed polypropylene powder, fully vulcanized powder silicone rubber (VP-602, particle diameter 0.2 μm, gel content 80%, Beijing Research Institute of Chemical Industry), antioxidant (antioxidant 1010 and antioxidant 168 is compounded at a weight ratio of 1: (1 to 4), BASF, Germany), and light stabilizer (BASF, Germany or Cytec, USA) are put into a high-speed mixer and stirred at a speed of 300 rpm For 3 minutes, the components were fully mixed and uniform; then the above-mentioned mixed material was passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com