Preparation process of formaldehyde alcoholic solution for polymethoxy dimethyl ether production

A polymethoxydimethyl ether and preparation process technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry and other directions, can solve the problem of high risk of high-concentration formaldehyde polymerization, low synthesis conversion rate and yield, and conversion In order to reduce the concentration temperature, avoid the risk of polymerization, and reduce the water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

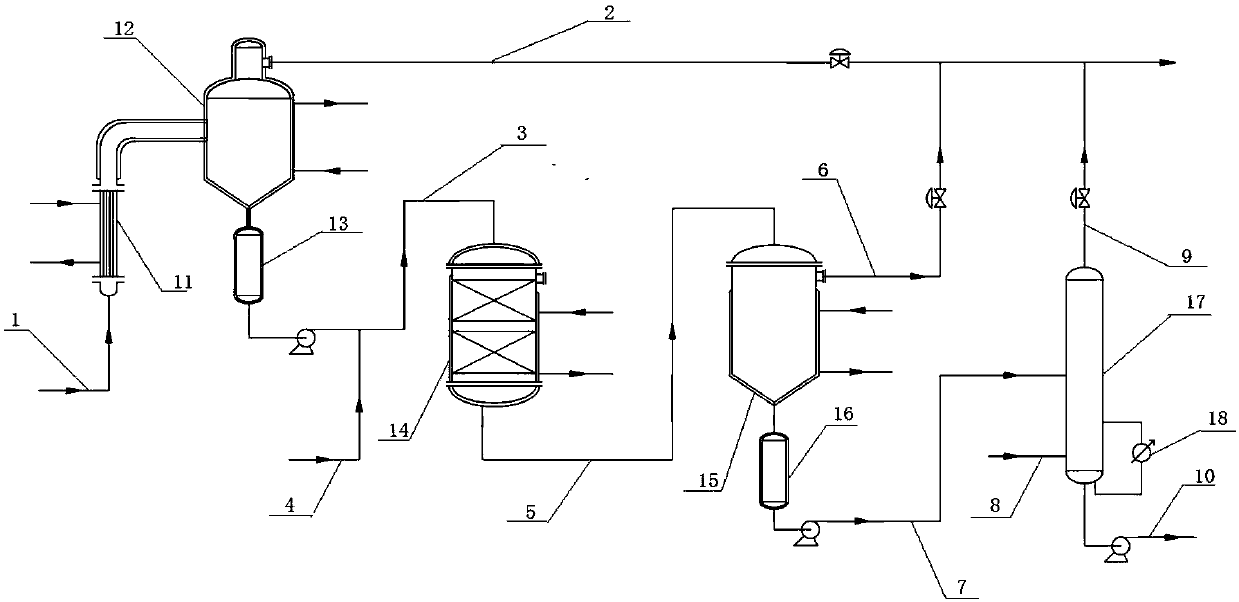

[0028] A preparation process of formaldehyde alcohol solution for the production of polymethoxydimethyl ether, comprising the following steps:

[0029] 1), the high concentration formaldehyde that the concentration is 50-55% is pumped into the bottom of the rising film evaporator 11 from the logistics 1, and the pressure in the rising film evaporator 11 is adjusted <20Kpa, so that formaldehyde is vaporized;

[0030] 2), enter the vaporized gas-liquid mixture of 1) gained into the I-level separator 12, the I-level separator 12 completes the gas-liquid phase separation, and the gas phase is sent to the subsequent unit through the stream 2 to obtain formaldehyde> 75% liquid phase is transferred into I Grade buffer tank 13 storage;

[0031] 3), the material in the first-level buffer tank 13 is pumped out by the discharge pump, mixed with a certain flow of methanol (stream 4) (stream 3) and then enters the reactor 14 to complete the hemiacetalization reaction with a small degree of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com