Sewage biological denitrification and dephosphorization device

A technology for denitrification, phosphorus removal, and biological sewage, which is applied in biological treatment devices, water pollutants, biological water/sewage treatment, etc. effect, effect of improving shock load resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

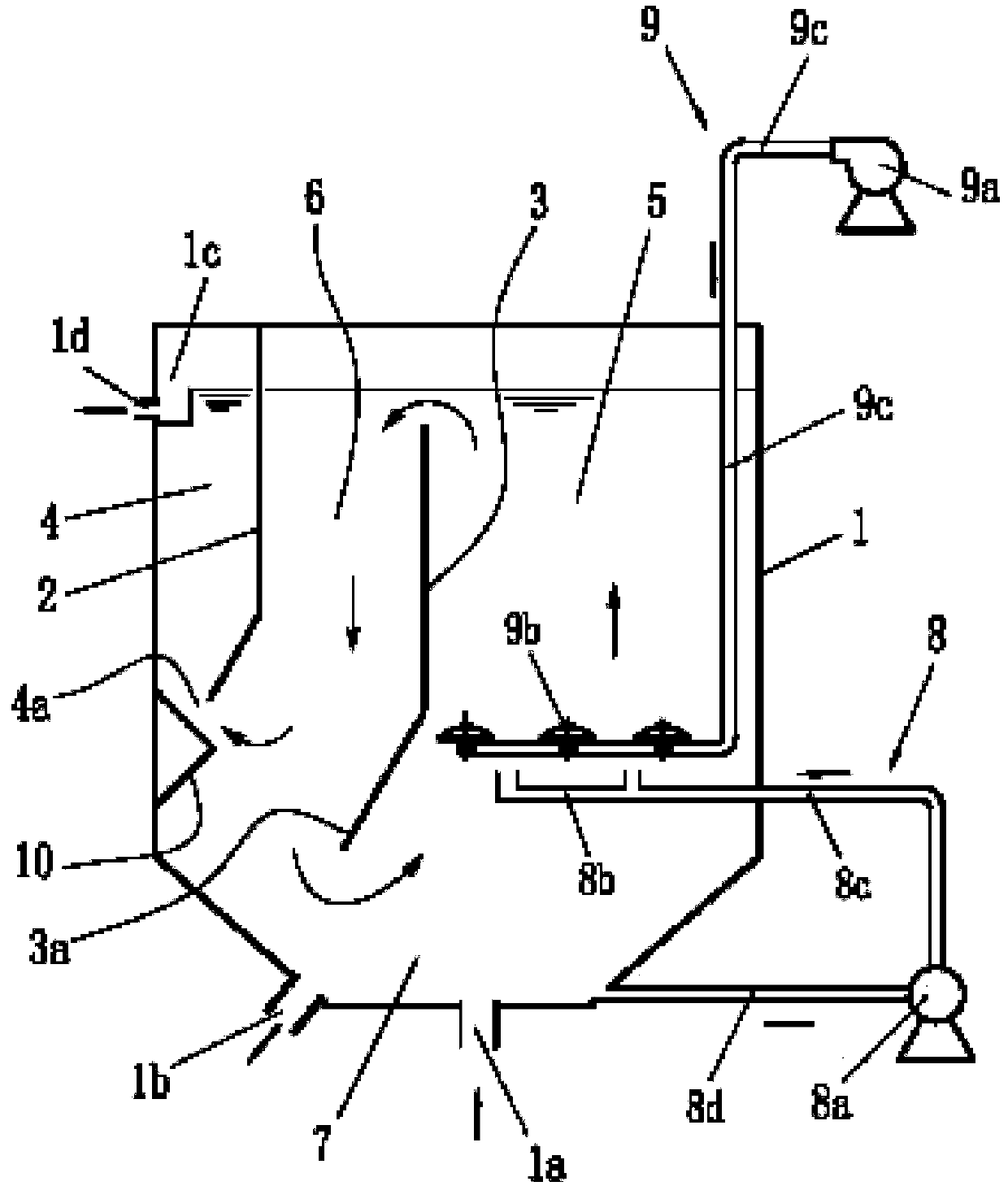

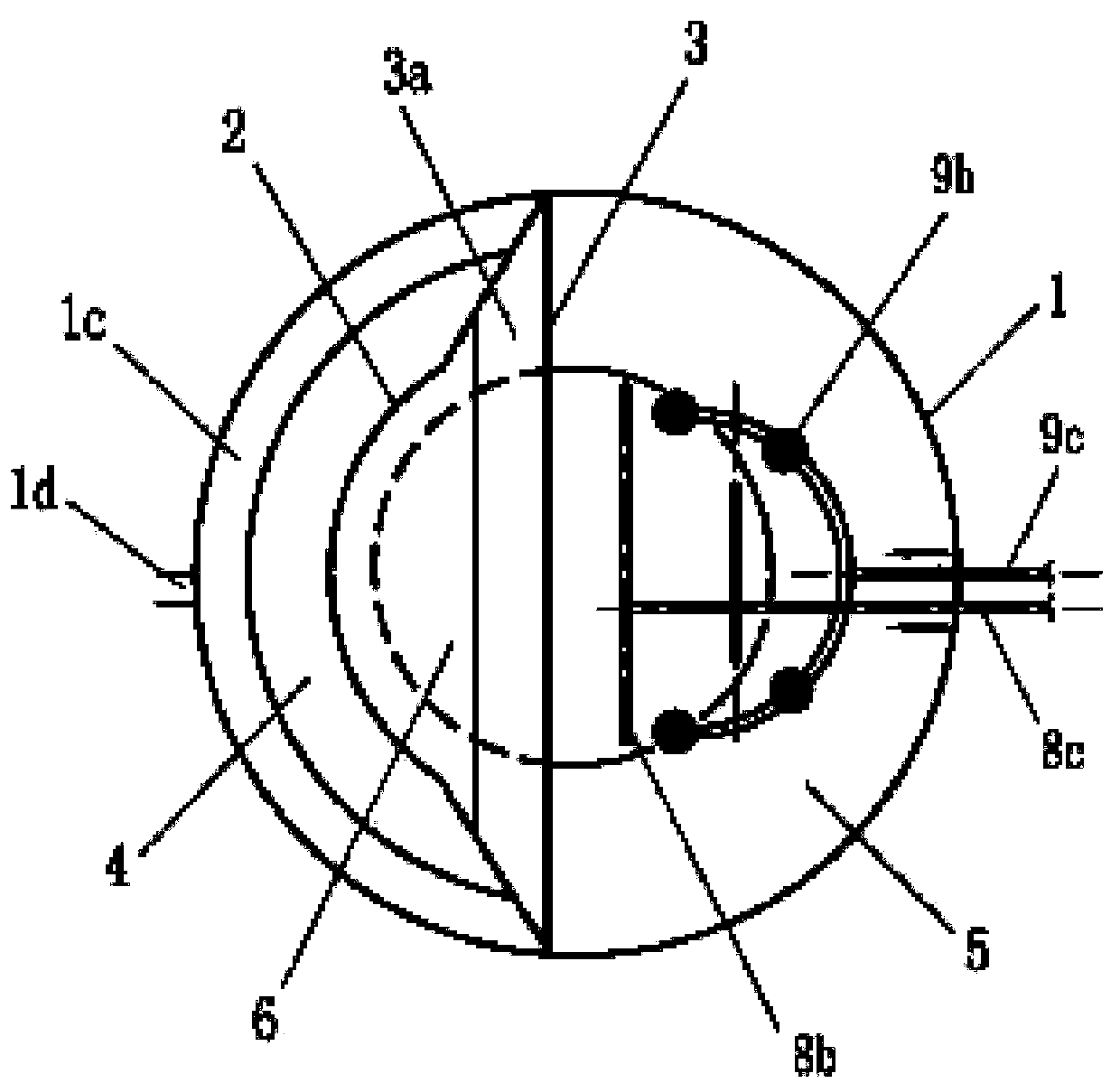

[0031] Referring to the accompanying drawings, the present invention includes a casing 1 of a vertical cylinder; the inner cavity of the casing 1 is provided with an outer vertical plate 2 and an inner vertical plate 3; the outer vertical plate 2 and the casing A mud-water separation zone 4 located in the middle and upper part of the housing is formed between the walls, and the upper part of the mud-water separation zone 4 communicates with the water outlet 1d; the inner vertical plate 3 divides the inner cavity of the housing 1 into two chambers, The chamber on one side of the inner vertical plate 3 is a water flow ascending channel 5, and the other side is a water flow descending channel 6, and the upper and lower ends of the water flow ascending channel 5 communicate with the upper and lower parts of the water flow descending channel 6 respectively, that is, in the shell A water circulation channel is formed in the body 1, and the inlet 4a of the mud-water separation area 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com