Scrap iron collecting device applied to machining

A collection device and mechanical processing technology, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of heavy iron scrap recovery device, incomplete recovery, slow recovery, etc., to achieve low production cost, The effect of thorough recovery and quick recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

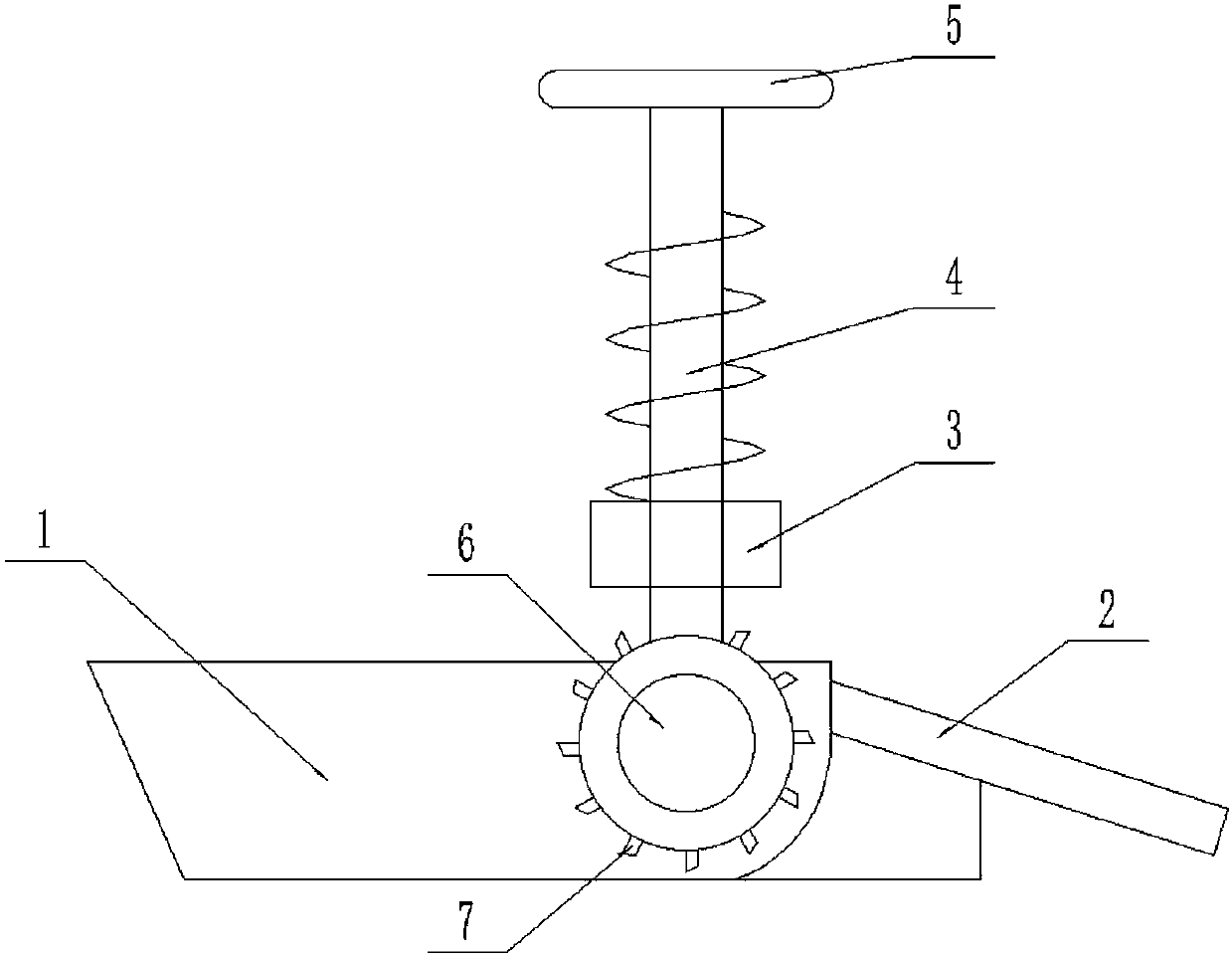

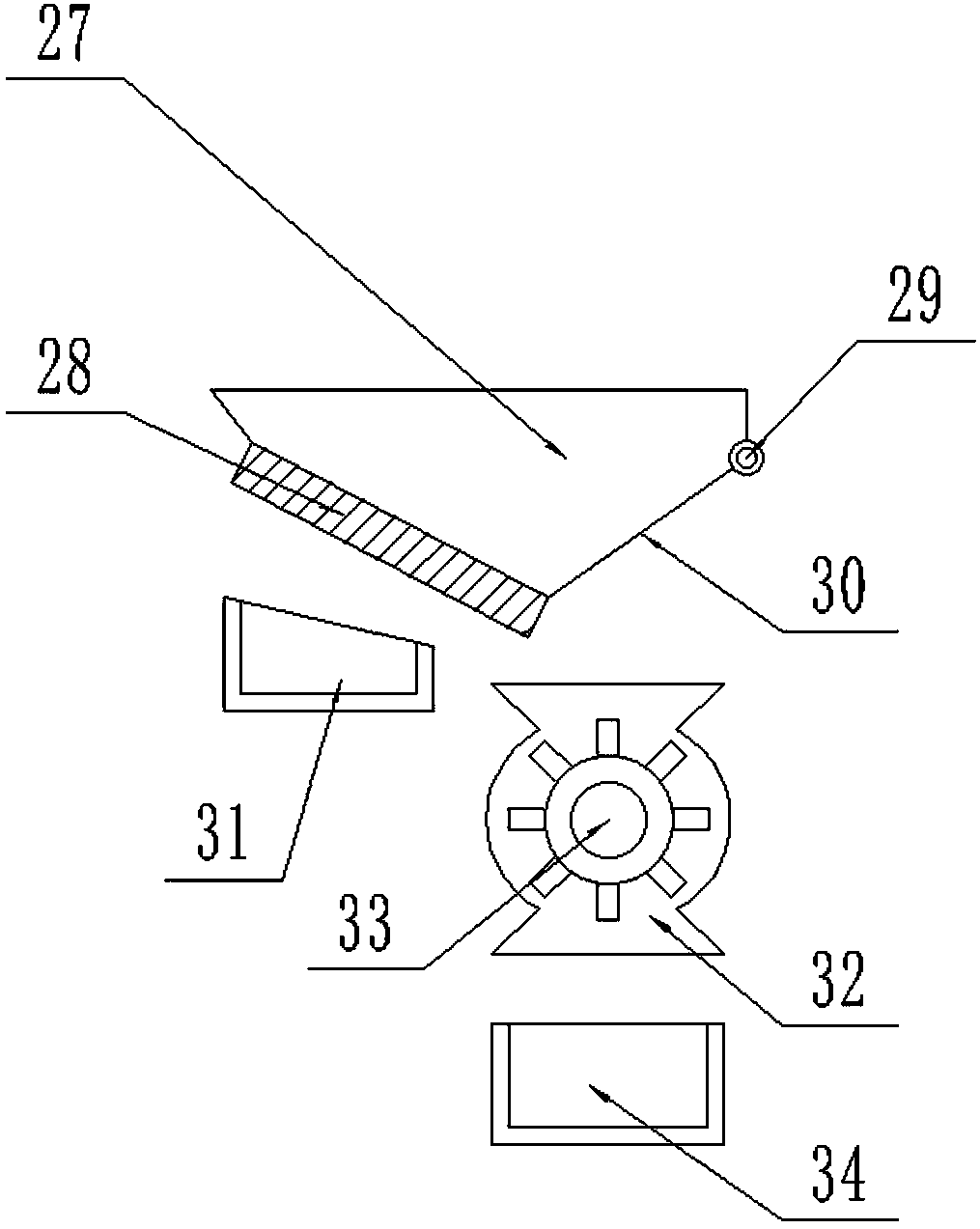

[0019] Such as Figure 1 to Figure 5 As shown, this specific embodiment adopts the following technical solutions: a chip collection device used in mechanical processing, including a collection tank 1, a swash plate 2, a fixed block 3, a screw rod 4, a hand wheel 5, a collection wheel 6, Collecting shovel 7, first cleaning chamber 8, first outlet pipe 9, first filter screen 10, water chamber 11, water pump 12, water pipe 13, nozzle 14, second cleaning chamber 15, isolation net 16, cleaning motor 17, cleaning Fan 18, the second water outlet pipe 19, the second filter screen 20, the fixed seat 21, the support 22, the screw rod 23, the driving motor 24, the connecting rod 25 and the electromagnetic chuck 26; the right side of the collection tank 1 is provided with an inclined Plate 2; a collection wheel 6 is provided in the chamber of the collection tank 1; several collection shovels 7 are fixedly connected to the outer surface of the collection wheel 6; the fixed block 3 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com