Flue gas desulfurization and denitration agent, preparation method and application thereof

A technology of desulfurization and denitrification, dry flue gas desulfurization, applied in the field of flue gas desulfurization and denitrification agent based on calcium carbide slag and its preparation, can solve the problems of high cost, huge equipment operation cost, no consideration of the use of denitrification agent, etc., and achieve simple preparation method , reduced dosage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The flue gas desulfurization and denitrification agent of the present invention can be prepared by conventional methods. For example, mix calcium carbide slag, magnesium oxide and catalyst evenly to obtain the product. In addition, the preparation method of the present invention also includes a processing step of carbide slag: the carbide slag product is dried, crushed and screened to obtain carbide slag with a particle size of less than 200 mesh.

[0041]

[0042] The flue gas desulfurization and denitrification agent of the invention is used for dry flue gas desulfurization and denitrification. According to one embodiment of the present invention, the desulfurization and denitration agent dry powder is fully mixed with the flue gas after pre-dust removal in the flue gas pipeline, and then enters the absorption tower for desulfurization and denitration treatment, and the desulfurized and denitrified flue gas is discharged from the chimney. The dry flue gas desulfuri...

Embodiment 1

[0056] The desulfurization and denitrification agent in this embodiment consists of 5 parts by weight of magnesium oxide, 3 parts by weight of catalyst and 92 parts by weight of carbide slag. The active magnesium oxide of magnesium oxide is greater than 70wt%, the particle size is less than 100 mesh powder, and the catalyst is TiO 2 Carbide slag is a finished product with a particle size of less than 200 mesh obtained after grinding the carbide slag product produced by the dry acetylene process. Carbide slag, magnesium oxide and catalyst are evenly mixed to obtain desulfurization and denitrification agent A1.

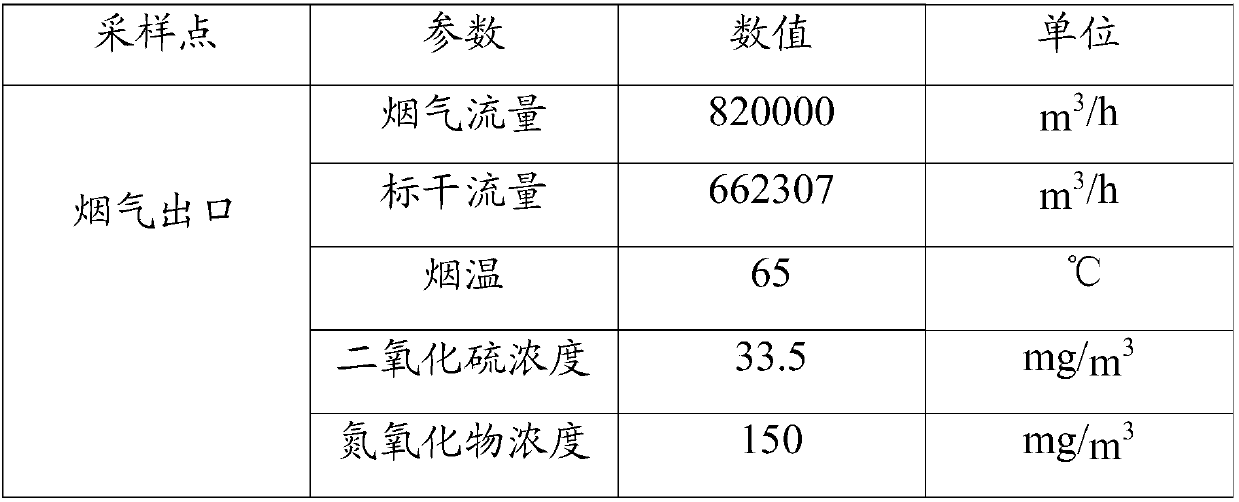

[0057] After desulfurization and denitrification with desulfurization and denitrification agent A1, the flue gas data at the outlet is detected, as shown in the table below.

[0058]

[0059] It can be seen from the table that the desulfurization efficiency of the desulfurization and denitrification agent can reach 95wt%, and the denitrification efficiency can reach...

Embodiment 2

[0061] The desulfurization and denitrification agent in this embodiment consists of 10 parts by weight of magnesium oxide, 2.4 parts by weight of catalyst and 87.6 parts by weight of carbide slag. The active magnesium oxide of magnesium oxide is greater than 75wt%, the particle size is less than 100 mesh powder, and the catalyst is Al(OH) 3 Carbide slag is a finished product with a particle size of less than 200 mesh obtained after grinding the carbide slag product produced by the dry acetylene process. Carbide slag, magnesium oxide and catalyst are evenly mixed to obtain desulfurization and denitrification agent A2.

[0062] After desulfurization and denitrification with desulfurization and denitrification agent A2, the flue gas data at the outlet is detected, as shown in the table below.

[0063]

[0064]

[0065] It can be seen from the table that the desulfurization efficiency of the desulfurization and denitrification agent can reach 96wt%, and the denitrification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com