Venturi injection pipe for dust remover

A Venturi nozzle and Venturi technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as excessive deformation, poor dust cleaning, and increased filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

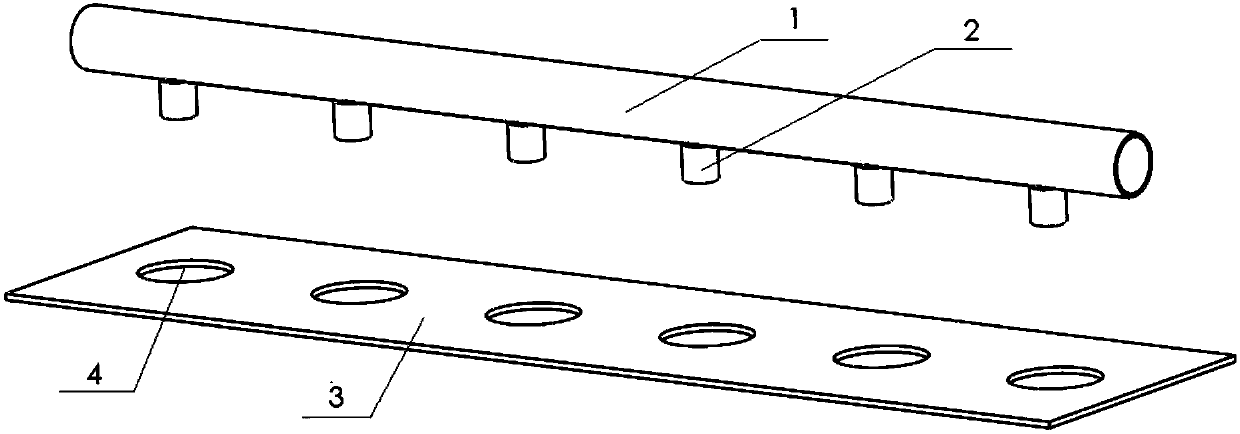

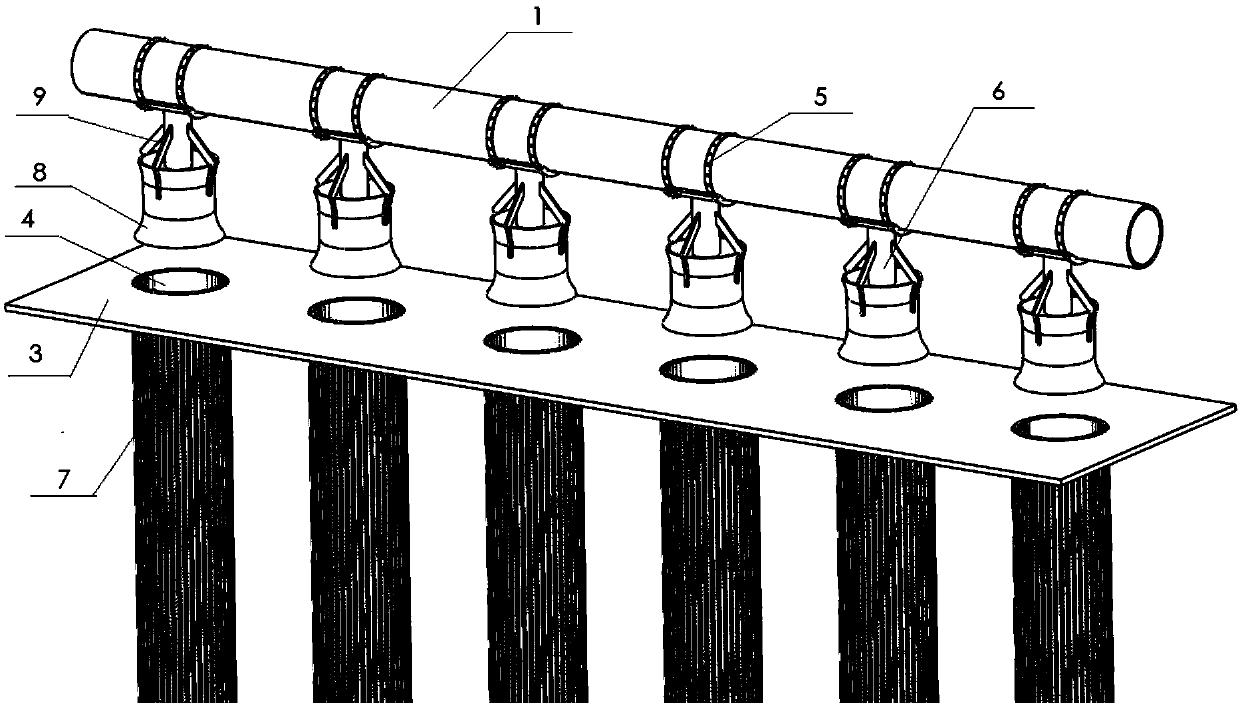

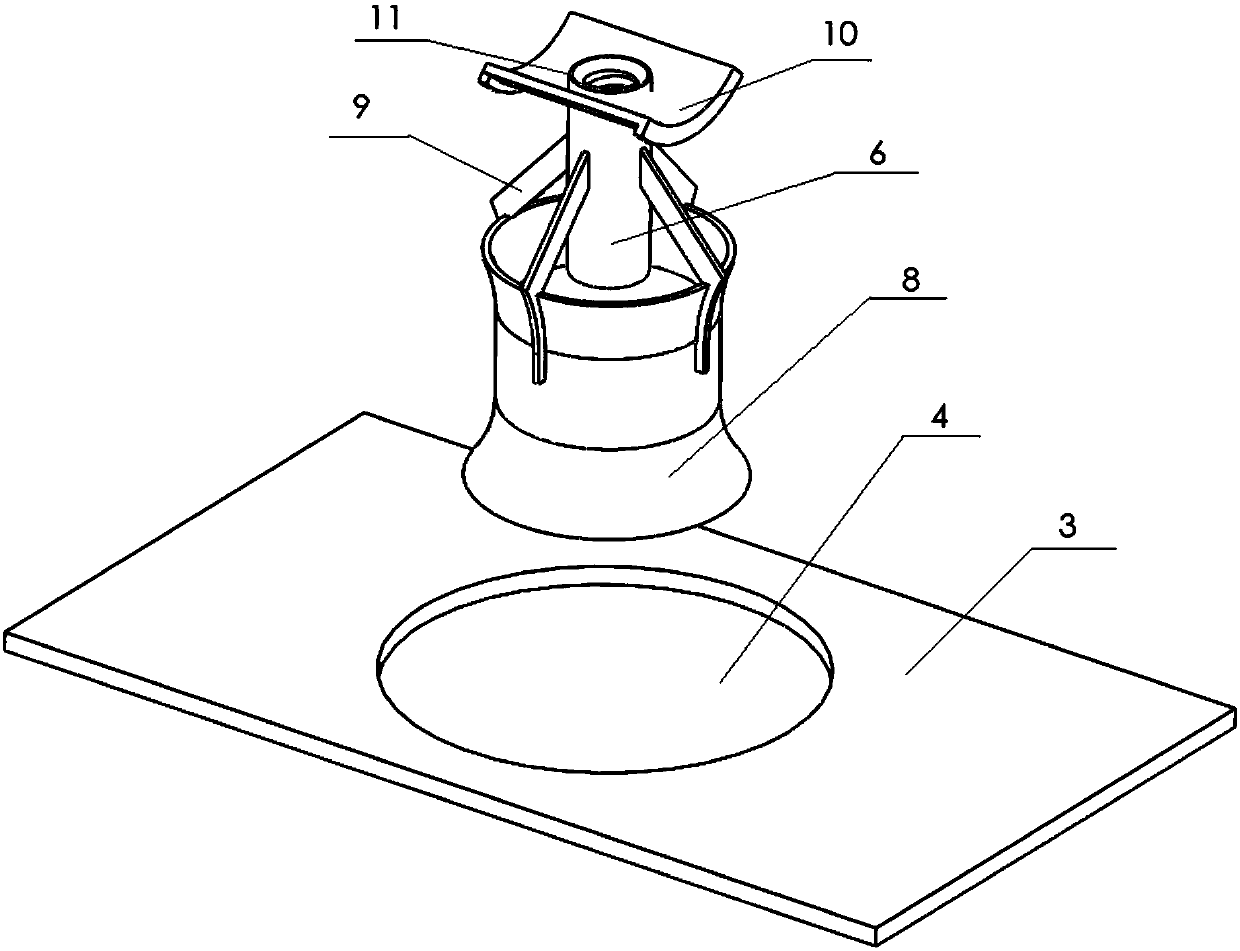

[0028] As shown in the figure, this embodiment discloses a Venturi blowing pipe for a dust collector, including a diffuser pipe 1, a Venturi nozzle, and a filter cartridge 7. The diffuser pipe 1 is provided with an air outlet, and the Venturi nozzle The upper end is fixedly arranged on the air outlet, and the lower opening of the Venturi nozzle 2 is arranged above the opening of the filter cartridge 7. It is characterized in that: the Venturi nozzle includes a housing 8, a jet pipe 6 and a reinforcing rib 9, and the housing 8 It is a hollow cylinder, and the upper and lower openings of the housing 8 are in the shape of a flared horn. The center of the housing 8 is provided with a jet tube 6 , and the outer periphery of the jet tube 6 is fixed to the outer wall of the housing 8 through a plurality of ribs 9 .

[0029] The manufacturing material of Venturi nozzle can be plastic, nylon, polyester and other non-metallic materials. It can adopt molding, injection molding and other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com