Medicine factory waste gas purification treatment device

A technology of waste gas purification and treatment device, which is applied in gas treatment, transportation and packaging, chemical instruments and methods, etc., can solve problems such as crop yield reduction, human poisoning, human stimulation, etc., and achieves good absorption and decomposition effect, simple structure, Design novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

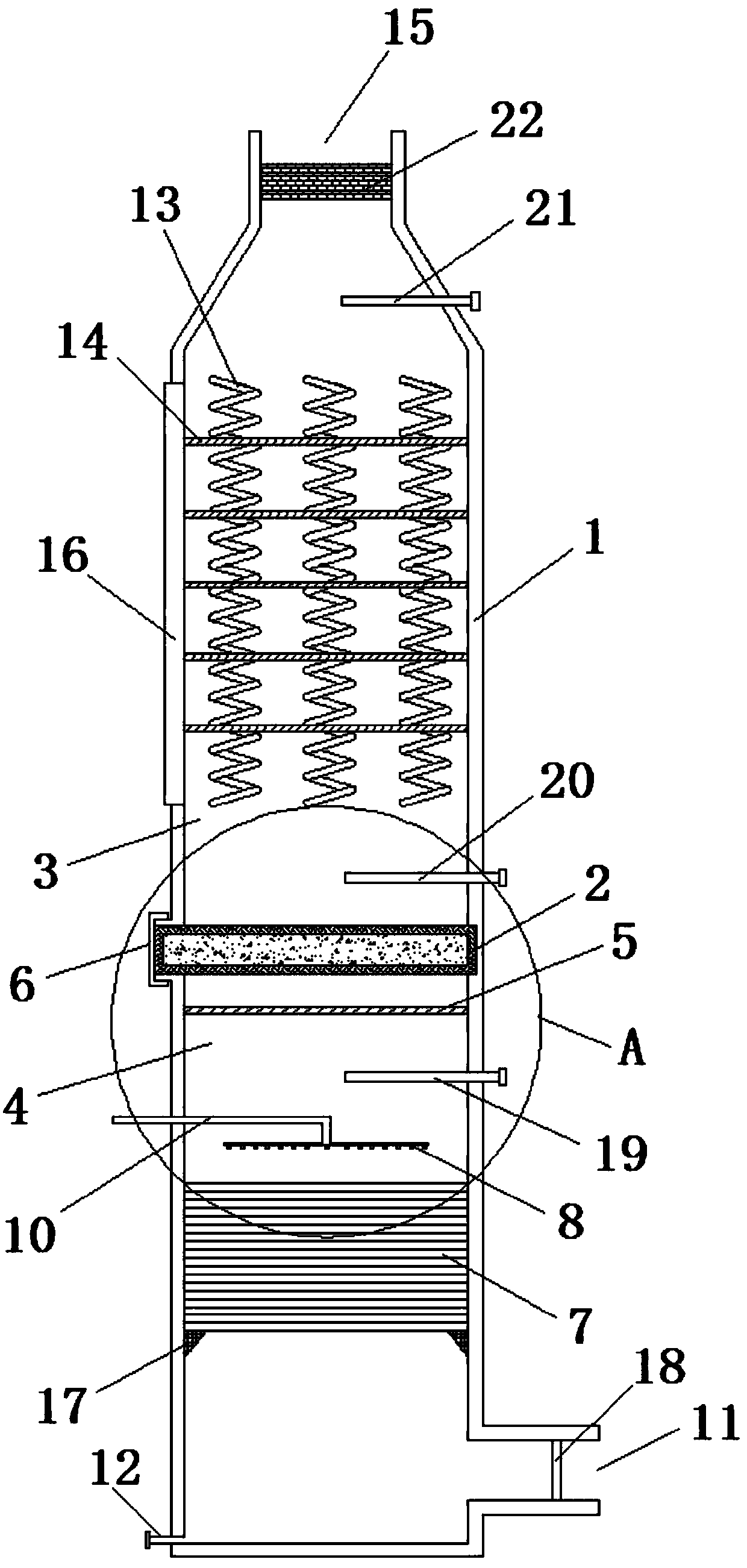

[0030] A device for purifying and treating exhaust gas from a pharmaceutical factory, comprising a purifying pipe 1, the purifying pipe 1 is a square pipe, a particulate pollutant filter box 2 is arranged in the middle of the purifying pipe 1, and a box body of the particulate pollutant filter box 2 It is a hollow structure with a high adsorption capacity activated carbon mixture inside. The particulate pollutant filter box 2 divides the purification pipe 1 into an upper photolysis pipe 3 and a lower absorption pipe 4, and the particulate pollutants filter A flow-sharing net unit 5 is installed 20cm below the box 2 to evenly diffuse the upward exhaust gas;

[0031] The particulate pollutant filter box 2 is a drawer-type structure, which can be inserted and drawn from the side wall of the purification pipe 1 to facilitate the replacement of the internal filling material. After being inserted, it is locked by the sealing cover 6;

[0032] The absorption pipe 4 is provided with multip...

Embodiment 2

[0038] A device for purifying and treating exhaust gas from a pharmaceutical factory, comprising a purifying pipe 1, the purifying pipe 1 is a square pipe, a particulate pollutant filter box 2 is arranged in the middle of the purifying pipe 1, and a box body of the particulate pollutant filter box 2 It is a hollow structure with a high adsorption capacity activated carbon mixture inside. The particulate pollutant filter box 2 divides the purification pipe 1 into an upper photolysis pipe 3 and a lower absorption pipe 4, and the particulate pollutants filter A flow-sharing net unit 5 is installed 20cm below the box 2 to evenly diffuse the upward exhaust gas;

[0039] The particulate pollutant filter box 2 is a drawer-type structure, which can be inserted and drawn from the side wall of the purification pipe 1 to facilitate the replacement of the internal filling material. After being inserted, it is locked by the sealing cover 6;

[0040] The absorption pipe 4 is provided with multip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com