Organic optical waveguide embedded PCB processing method

A processing method and optical waveguide technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems such as the production method of organic optical waveguide embedded PCB, which is convenient for commercial promotion, improves alignment accuracy, and is suitable for large-scale The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

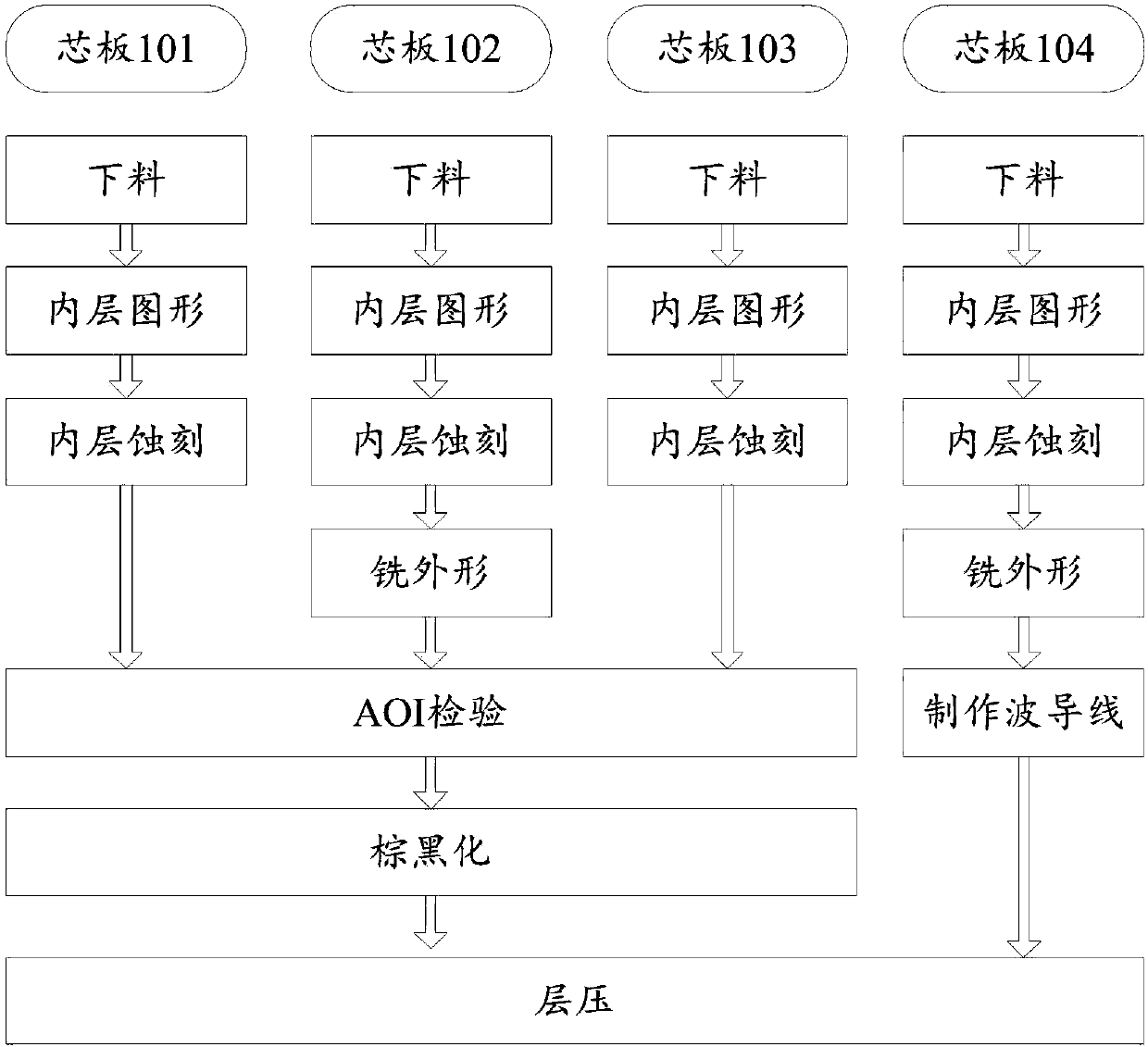

Image

Examples

Embodiment 1

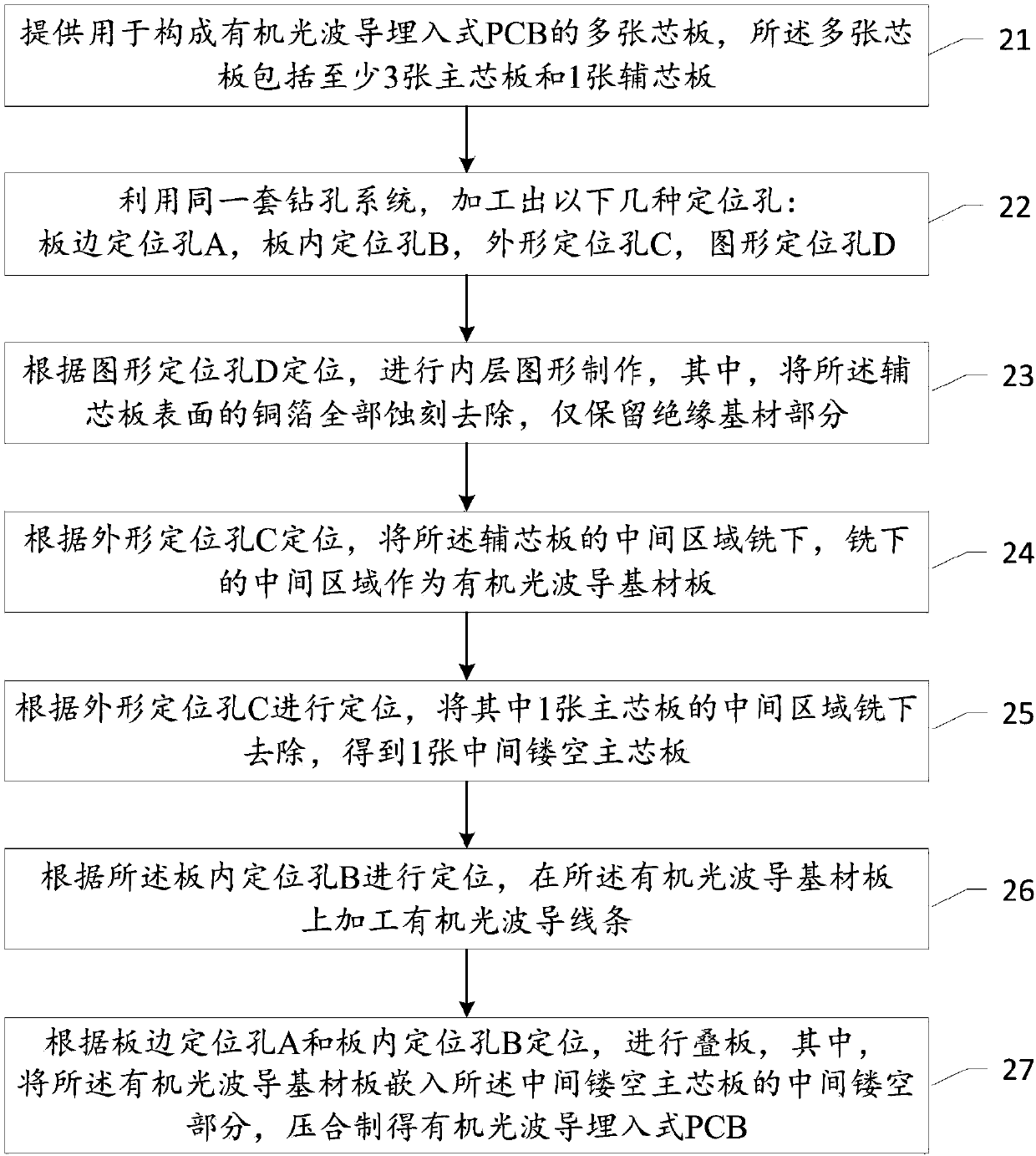

[0071] Please refer to figure 2 , this embodiment provides a method for processing an organic optical waveguide embedded PCB, using hole positioning to manufacture organic optical waveguide strips, the method may include:

[0072] 21. Provide multiple core boards for forming an organic optical waveguide embedded PCB, the multiple core boards include at least 3 main core boards and 1 auxiliary core board;

[0073] 22. Use the same drilling system to drill the multiple core boards, and process the following positioning holes: board edge positioning hole A for lamination positioning, for organic optical waveguide processing positioning and lamination Positioning hole B in the board for positioning, shape positioning hole C for positioning the inner core board milling shape, and graphic positioning hole D for making and positioning the inner layer of the core board;

[0074] 23. Perform positioning according to the pattern positioning hole D, and make inner layer patterns for th...

Embodiment 2

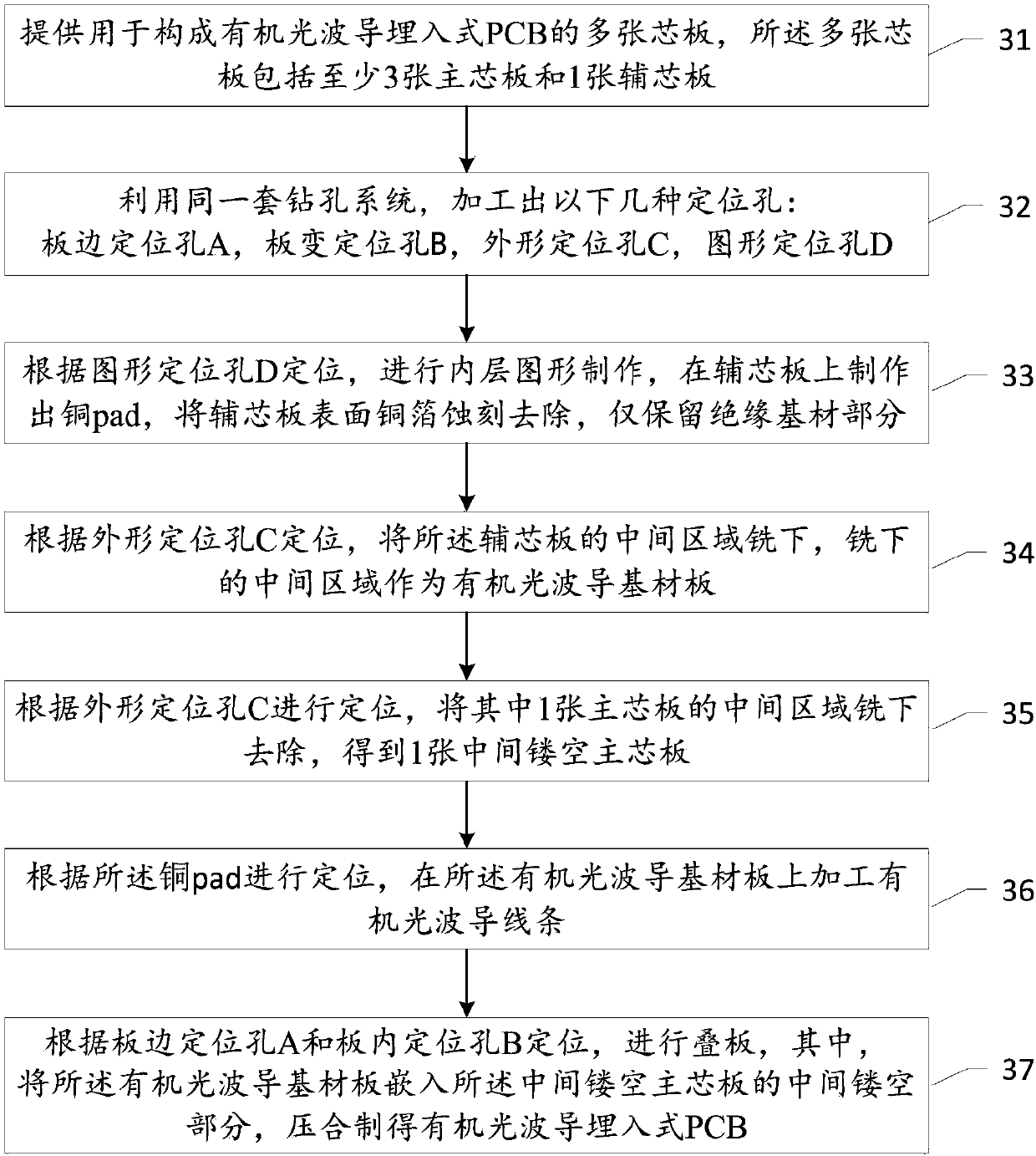

[0085] Please refer to image 3 , the present embodiment provides a method for processing an organic optical waveguide embedded PCB, using graphic positioning to manufacture organic optical waveguide strips, the method may include:

[0086] 31. Provide multiple core boards for forming an organic optical waveguide embedded PCB, the multiple core boards include at least 3 main core boards and 1 auxiliary core board;

[0087] 32. Use the same drilling system to drill the multiple core boards, and process the following positioning holes: board edge positioning hole A for lamination positioning and board inner positioning hole B for inner layer Shape positioning hole C for core board milling shape positioning, and graphic positioning hole D for core board inner layer graphics making and positioning;

[0088] 33. Perform positioning according to the pattern positioning hole D, and make inner layer patterns on the plurality of core boards, wherein a copper pad for processing and pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com