Portable composite trekking bridge

A composite material and pedestrian bridge technology, applied in portable bridges, bridges, bridge parts, etc., can solve the problems of difficult carrying, high labor intensity of erection operations, and self-heavy weight, etc., to improve the erection and assembly speed, reduce self-weight, and enhance bearing capacity. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

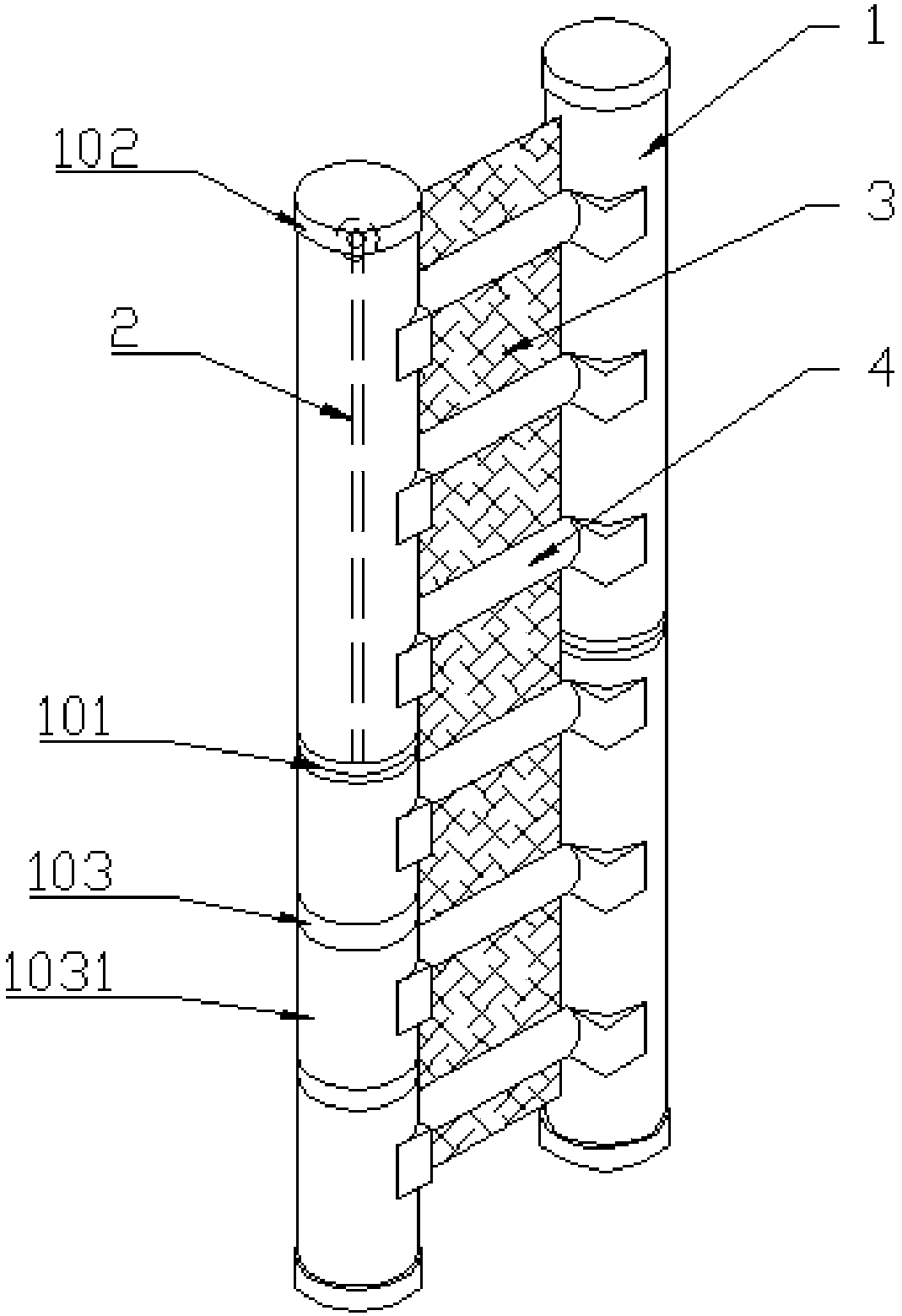

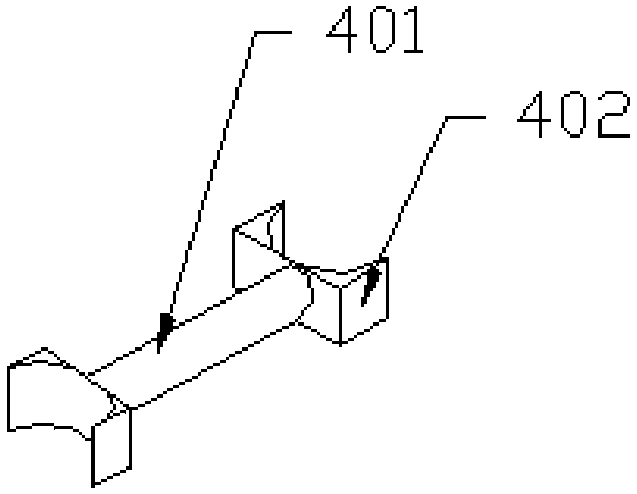

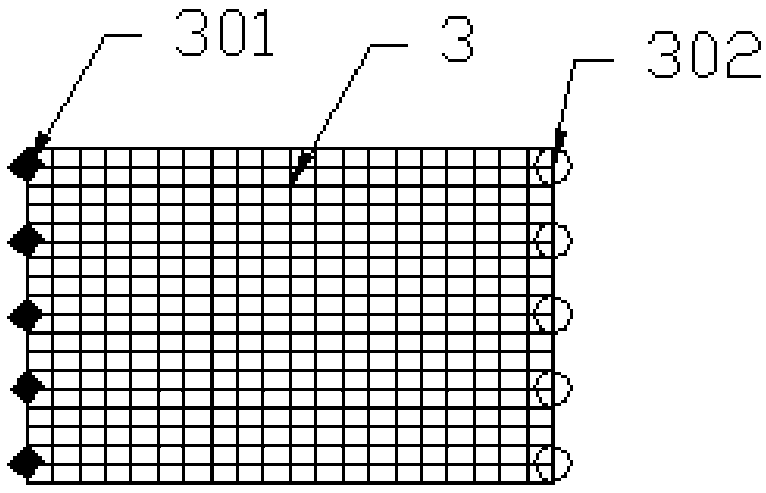

[0029] The present embodiment provides a kind of portable composite material pedestrian bridge, structure such as figure 1 As shown, the pedestrian bridge comprises two main girder assemblies 1 arranged in parallel, and several cross beam assemblies 4 are installed vertically between the two main girder assemblies, and bridge deck 3 is set in the area surrounded by cross girder assemblies 4 and main girder assemblies 1; Assembly 1 includes several bushing beam assemblies 103 connected end to end, bidirectional metal sleeves 101 pass between casing beam assemblies 103, one-way metal sleeves 102 are installed on the two outer ends of main beam assembly 1, and casing beam assemblies 103 is composed of several coaxial pipe fitting units 1031 with successively reduced cross-sections; prestressed cables 2 are installed inside the main beam assembly 1 along its extension direction, and the two ends of the prestressed cables 2 are respectively connected to the main beam The one-way me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com