Odor-removal anti-radiation VAE (Vinyl Acetate Ethylene) interior wall coating and preparation method thereof

An interior wall coating and anti-radiation technology, applied in the field of coatings, can solve the problems of easy precipitation and layering of anti-radiation conductive materials, affecting the effect of anti-radiation, etc., and achieve excellent anti-radiation performance and storage performance, excellent anti-odor, anti-radiation, and storage good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

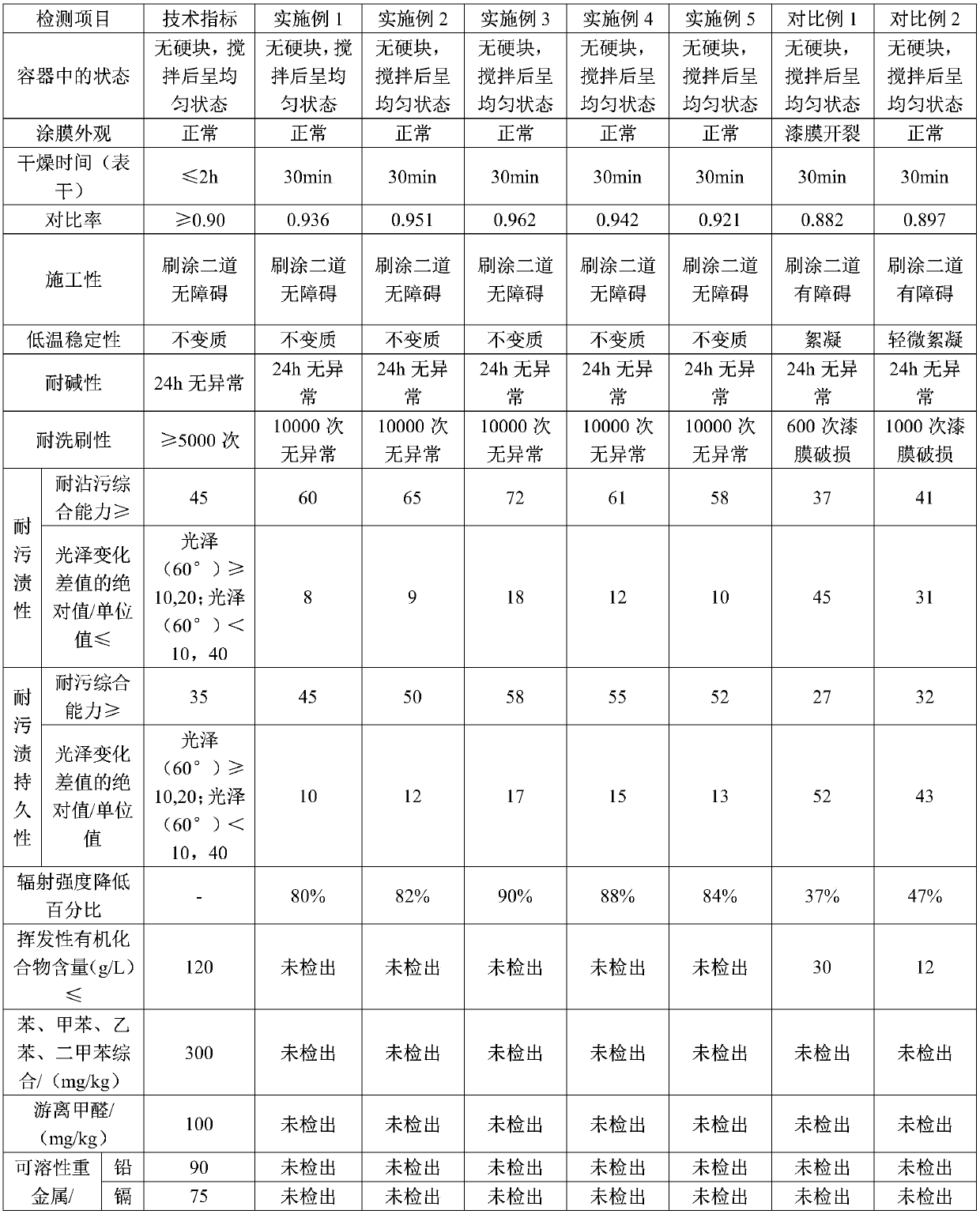

Examples

Embodiment 1

[0036] In this embodiment, the anti-odour VAE interior wall paint A is prepared from the following raw materials in terms of mass percentage: 45% modified VAE emulsion, 15% titanium dioxide, 7% kaolin, 8% heavy calcium, water 23%, wetting agent 0.1%, dispersant 0.6%, pH regulator 0.3%, defoamer 0.3%, preservative 0.2%, thickener 0.5%;

[0037] Wherein, the preparation method of described modified VAE emulsion is as follows:

[0038] (1) Mix the anti-radiation material and vinyl tertiary carbonate at a mass ratio of 9:1, and disperse at a high speed of 1200r / min to obtain a mixed slurry with a fineness of 20um;

[0039](2) The mixed slurry obtained in step (1) is mixed with vinyl acetate, ethylene, and vinyl tertiary carbonate according to a mass ratio of 15:8:8:6, and then mixed in emulsifier, protective colloid, reducing agent, deionized water Under the influence of high-speed stirring to obtain a pre-emulsion; wherein the emulsifier is a mixture of sodium lauryl sulfate and...

Embodiment 2

[0042] In this embodiment, the anti-odour VAE interior wall paint B is prepared from the following raw materials in terms of mass percentage: 35% of modified VAE emulsion, 17% of titanium dioxide, 8% of kaolin, 9% of heavy calcium, water 29%, wetting agent 0.3%, dispersant 0.5%, pH regulator 0.1%, defoamer 0.2%, preservative 0.3%, thickener 0.6%;

[0043] Wherein, the preparation method of described modified VAE emulsion is as follows:

[0044] (1) Mix the anti-radiation material and vinyl tertiary carbonate at a mass ratio of 7:2, and disperse at a high speed of 1300r / min to obtain a mixed slurry with a fineness of 18um;

[0045] (2) The mixed slurry obtained in step (1) is mixed with vinyl acetate, ethylene, and vinyl tertiary carbonate according to a mass ratio of 12:11:10:8, and then mixed in emulsifier, protective colloid, reducing agent, deionized water Under the influence of high-speed stirring to obtain a pre-emulsion; wherein the emulsifier is a mixture of sodium lau...

Embodiment 3

[0048] In this embodiment, the anti-odor and anti-radiation VAE interior wall paint C is prepared from the following raw materials in terms of mass percentage: 41% of modified VAE emulsion, 17.5% of titanium dioxide, 8% of kaolin, 9% of heavy calcium, water 22%, wetting agent 0.4%, dispersant 0.6%, pH regulator 0.2%, defoamer 0.3%, preservative 0.3%, thickener 0.7%;

[0049] Wherein, the preparation method of described modified VAE emulsion is as follows:

[0050] (1) Mix the anti-radiation material and vinyl tertiary carbonate at a mass ratio of 8:1, and disperse at a high speed of 1400r / min to obtain a mixed slurry with a fineness of 20um;

[0051] (2) The mixed slurry obtained in step (1) is mixed with vinyl acetate, ethylene, and vinyl tertiary carbonate according to a mass ratio of 13:13:13:11, and then mixed in emulsifier, protective colloid, reducing agent, deionized water Under the influence of high-speed stirring to obtain a pre-emulsion; wherein the emulsifier is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com