Positionable stainless steel tube inner wall polishing device

A polishing device and technology for stainless steel tubes, applied in grinding/polishing equipment, machine tools designed for grinding workpiece rotating surfaces, grinding machines, etc., can solve the problem that stainless steel tubes cannot be perfectly connected with processing equipment, reduce the polishing effect of stainless steel tubes, and prevent workers from The impact of the mouth on the polishing wheel and other problems can be achieved to improve stability and safety, avoid sticking and damage, and achieve good safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

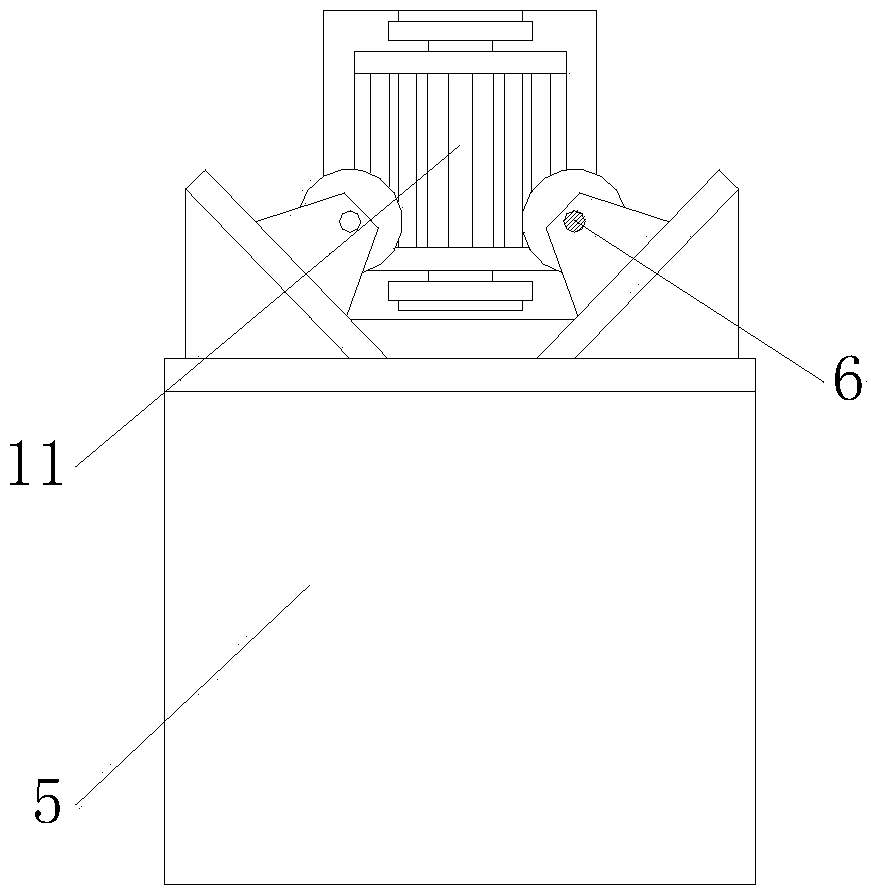

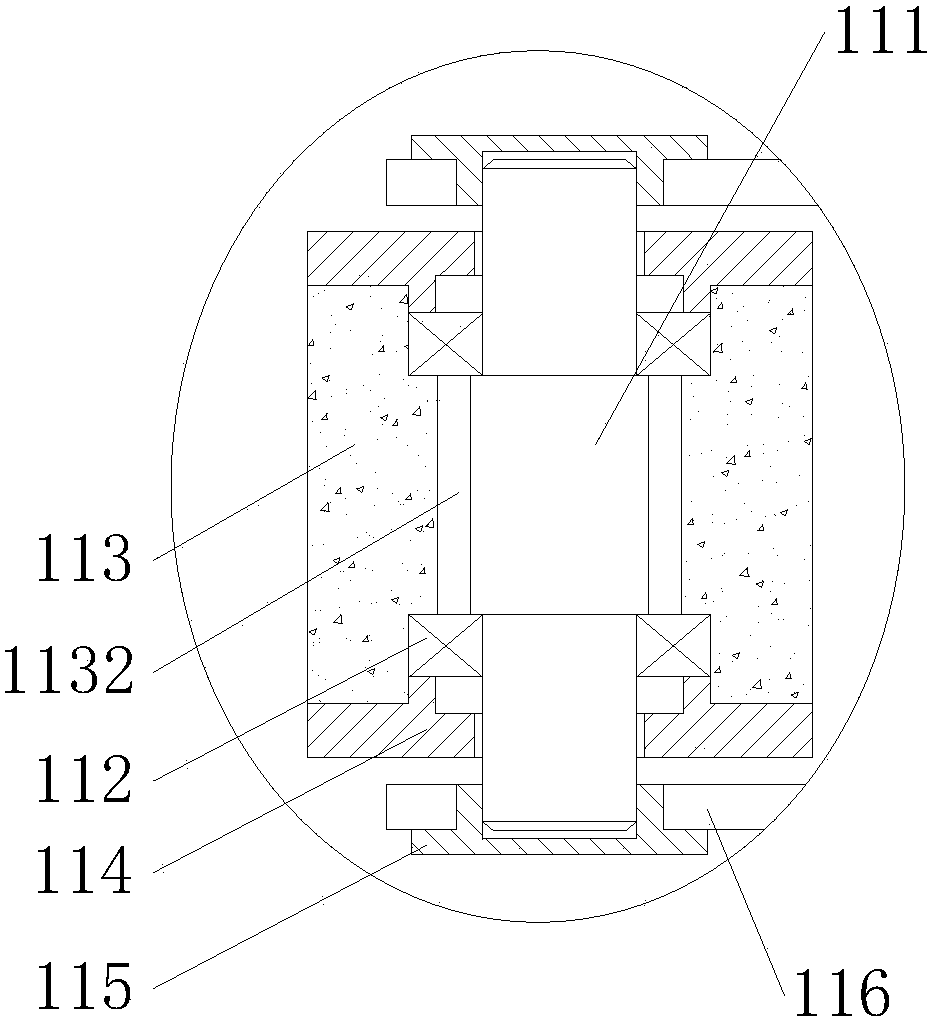

[0016] Example. A positionable polishing device for the inner wall of a stainless steel tube is constituted as Figure 1-5 As shown, it includes a frame 1, a group of parallel conveying tracks 2 are arranged at one end of the top of the frame 1, a polishing machine 3 is arranged on the conveying track 2, and first rollers fixed on the frame 1 are arranged in turn on one side of the conveying track 2 Group 4 and the second roller group 5, a roller in the first roller group 4 and a roller in the second roller group 5 are connected to each other through a connecting shaft 6, and one end of the connecting shaft 6 is provided with a rotating gear 7, and the rotating gear 7 is driven Chain 8 connects drive gear 9, and drive gear 9 one end is connected with the drive motor 10 that is fixed on the frame 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com