Acryl binder for lithium-sulfur secondary battery cathode

A sulfur secondary battery and binder technology, which is applied in the positive electrode field of lithium-sulfur secondary batteries, can solve the problems of high solubility of lithium sulfide, low life characteristics and output characteristics, poor stability, etc., to ensure electrochemical characteristics, excellent Cycling characteristics, effect of preventing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0134] [Resin production example 1] - Production of acrylic adhesive (A1)

[0135]In a 250 mL round bottom flask, charge 7.5 g of polyethylene oxide methyl ether methacrylate, 6.0 g of N-vinyl-2-pyrrolidone, 1.5 g of acrylonitrile, and 60 g of water, and seal the inlet. Oxygen was removed by nitrogen bubbling for 30 minutes, the reaction flask was immersed in an oil bath heated to 60° C., and then 0.03 g of V-50 (Wako Chemical) was added to initiate the reaction. When the monomer conversion rate was 87% within 24 hours, the reaction was terminated to obtain an acrylic adhesive having a weight average molecular weight of about 300,000.

manufacture example 2~4

[0136] [Resin production examples 2 to 4] Production of acrylic adhesives (A2, A3, A4)

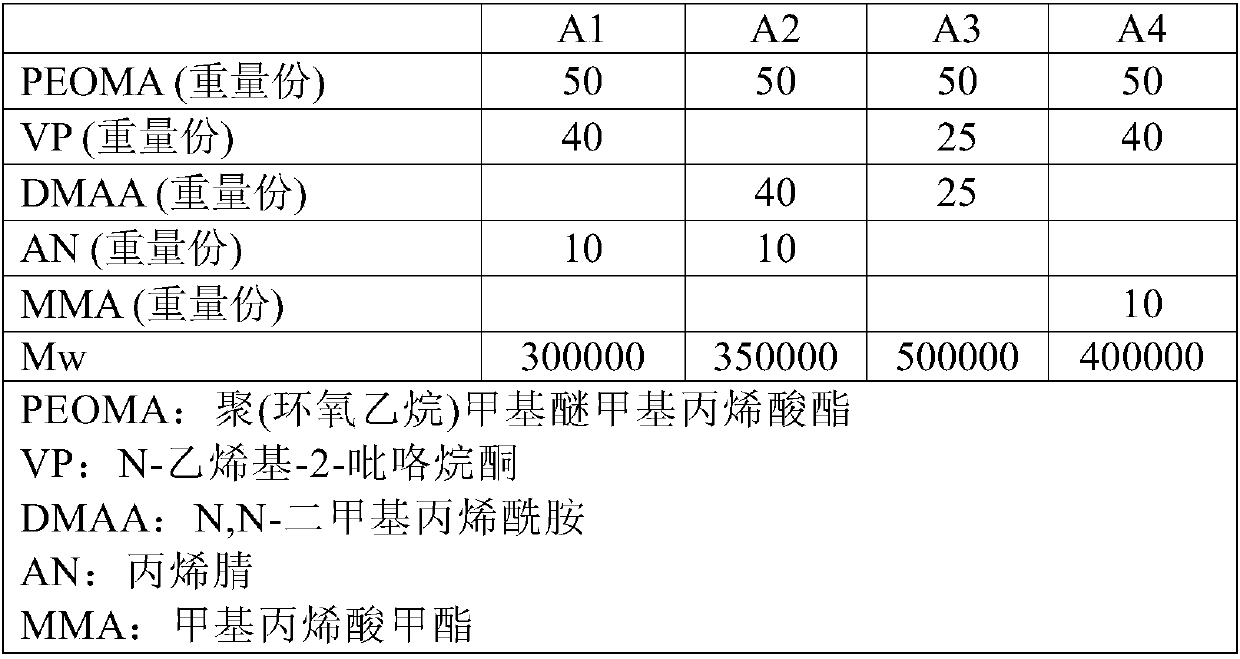

[0137] An acrylic adhesive was prepared in the same manner as in Production Example 1 except that the kind and content of monomers used at the time of polymerization were adjusted as shown in Table 1 below.

[0138] [Table 1]

[0139]

Embodiment 1

[0140] [Example 1] Manufacture of lithium-sulfur secondary battery

[0141] A lithium-sulfur secondary battery was fabricated using a positive electrode having an active layer containing the acrylic binder (A1) prepared according to Production Example 1 above. Charge / discharge was evaluated by performing 50 cycles between 1.5V and 2.8V at 0.1C / 0.1C, and then the remaining capacity in the second cycle and the remaining capacity in the 50th cycle were calculated relative to the initial capacity. The remaining capacity was measured to measure the capacity retention rate, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap