A kind of synthetic method of using iron tailings as raw material to prepare bismuth-doped lithium ferrous silicate cathode material

A technology of lithium ferrous silicate and cathode material, applied in silicate, alkali metal silicate, battery electrodes, etc., can solve the problem of not achieving full utilization of iron tailings, low economic benefits, and low added value of products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

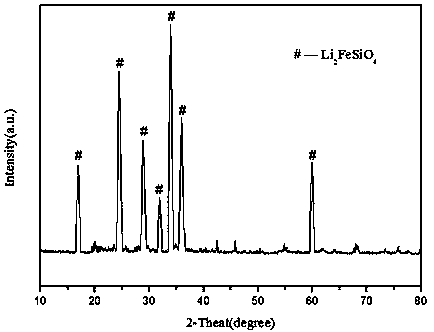

example 1

[0024] The iron tailings are ball milled to below 400 mesh, and the mass ratio iron tailings: caustic soda = 1:4 is used for batching and mixing. The obtained mixture is heated and activated in a microwave oven. The power of the microwave oven is adjusted to 1500MHz, the temperature is 810°C, and the heating time After the mixture is activated, quickly pour it into water according to the mass ratio of mixture: water = 1:25, put the above mixed solution in a silicone oil bath at 160°C, stir and react for 6 hours, filter after the reaction, and the obtained filtrate is Sodium silicate solution; by molar ratio SiO 3 2- : Fe 2+ = 1:1, add ferric nitrite to the sodium silicate solution, then fully stir and react in a silicone oil bath at 120°C for 4 hours; And dry at 100°C for 8 hours to obtain a precipitate; then molar ratio of Fe 2+ : Li + : Bi 3+ =1:2:0.01, mix lithium oxide and bismuth trioxide into the sediment, and after mixing thoroughly, put the mixture in a muffle f...

example 2

[0026] The iron tailings are ball milled to below 400 mesh, and the mass ratio of iron tailings: caustic soda = 1:3 is used for batching and mixing. The obtained mixture is heated and activated in a microwave oven. The power of the microwave oven is adjusted to 2000MHz, and the temperature is 850°C. After the mixture is activated, quickly pour it into water according to the mass ratio of mixture: water = 1:25, put the above mixed solution in a silicone oil bath at 160°C, stir and react for 6 hours, filter after the reaction, and the obtained filtrate is Sodium silicate solution; by molar ratio SiO 3 2- : Fe 2+ = 1:1, add ferric nitrite to the sodium silicate solution, then fully stir and react in a silicone oil bath at 120°C for 4 hours; And dry at 100°C for 8 hours to obtain a precipitate; then molar ratio of Fe 2+ : Li + : Bi 3+ =1:2:0.015, mix lithium oxide and bismuth trioxide into the sediment, after mixing thoroughly, put the mixture in a muffle furnace for calcin...

example 3

[0028] Ball mill the iron tailings to less than 400 mesh, and carry out batching and mixing according to the mass ratio of iron tailings: caustic soda = 1:3. The obtained mixture is heated and activated in a microwave oven. The power of the microwave oven is adjusted to 2500MHz, and the temperature is 850°C. After the mixture is activated, quickly pour it into water according to the mass ratio of mixture: water = 1:25, place the above mixture in a 160°C methyl silicone oil bath, stir and react for 6 hours, filter after the reaction, and obtain the filtrate It is sodium silicate solution; by molar ratio SiO 32- : Fe 2+ =1:1, add ferric nitrite to the sodium silicate solution, then fully stir and react in a silicone oil bath at 120°C for 4 hours; and dried at 100°C for 7 hours to obtain a precipitate; then molar ratio of Fe 2+ : Li + : Bi 3+ =1:2:0.02, mix lithium oxide and bismuth trioxide into the sediment, after mixing thoroughly, place the mixture in a muffle furnace f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com