Composite high-refractive spectacle lens

A spectacle lens and coating technology, which is applied in the field of optical lenses, can solve the problems of low refractive index, inferior to resin lenses, and fragile market share, and achieve the effects of good pressure resistance, reduced thickness, and overcoming fragility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

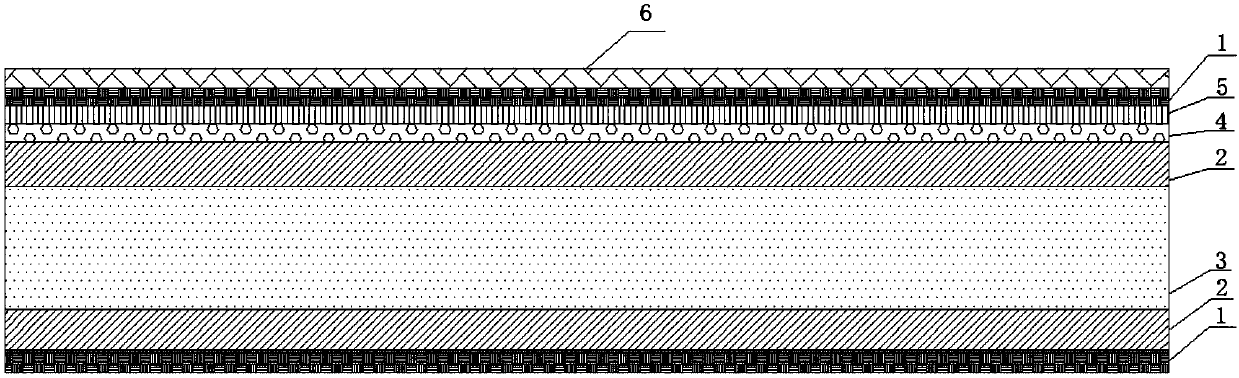

[0013] A composite high-fold eyeglass lens, graphene fiber coating 1, PMMA soft film layer 2, chemically strengthened aluminum silicate glass layer 3, PMMA soft film layer 2, zirconium dioxide coating 4, and titanium dioxide arranged sequentially from the inside to the outside Coating layer 5, graphene fiber coating layer 1 and anti-fouling film 6; the chemically strengthened aluminum silicate glass layer 3 is made of "Dragontrail" glass; the thickness of the PMMA soft film layer 2 is the thickness of the chemically strengthened aluminum silicate glass layer 3 1 / 8-1 / 10. The thickness of the graphene fiber coating 1, the zirconium dioxide coating 4, and the titanium dioxide coating 5 are all less than 50nm. In this embodiment, the above-mentioned coatings are all set to 45nm. If the coating thickness is too thick, it will easily affect the transmittance and refractive index of the lens. Optical performance. The antifouling film 6 is a vacuum-plated fluoride film with a thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com