Projectile explosive charge expansion pressure simulation test system and method

A technology of expansion pressure and pressure testing, which is applied to the measurement of blasting force and the measurement of the change force of the optical properties of the material when it is stressed, which can solve the problem that the expansion characteristics of the projectile explosive charge and semi-solid state explosives cannot be satisfied. Accurate measurement and other issues, to achieve the effect of large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

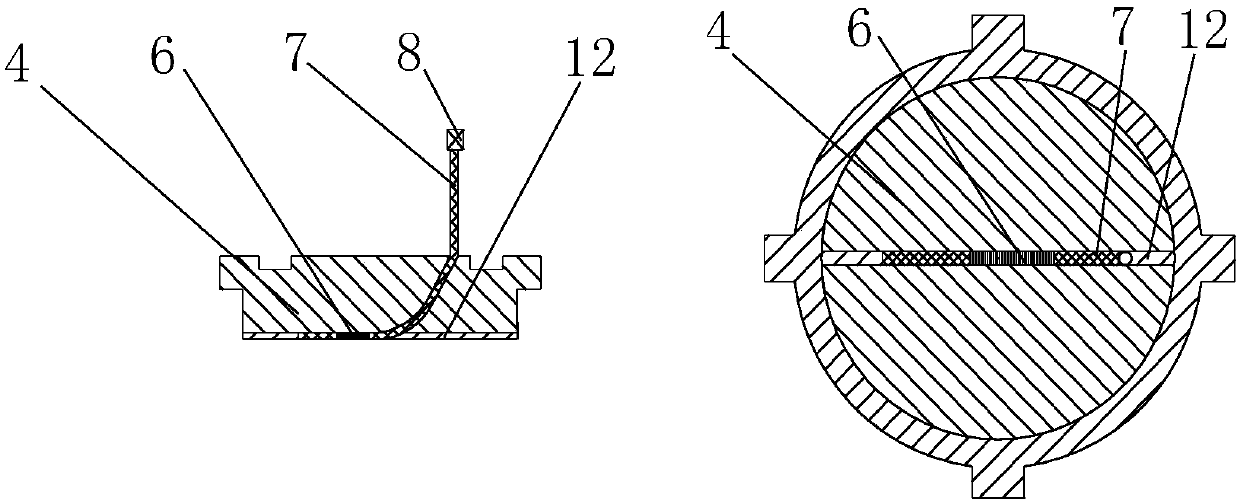

[0025] as figure 1 As shown, the projectile explosive charge expansion pressure simulation test system provided by the present invention includes a charge simulation chamber 2, an expansion pressure sensor assembly, a sealing compression nut 5, an explosive charge test piece 3, a constant temperature system 1, a temperature compensation Fiber grating 16, fiber demodulation system 14, measurement control system 15, etc. The combination of the explosive simulation chamber 2, the expansion pressure sensor assembly, the sealing compression nut 5, and the explosive charge test piece 3 constitutes a scaled simulation projectile. is 30mm. The charging simulation chamber 2 is in the shape of a barrel, which is made of stainless steel. The inner wall of the barrel is smooth and flat, with an inner diameter of about 31mm and an outer diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com