Method for extracting hyaluronic acid from rana chensinensis skin

A technology of hyaluronic acid and frog skin, applied in the biological field, can solve the problems of complicated steps, low HA extraction rate and low HA extraction rate, and achieve the effects of improving extraction rate, high purity and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

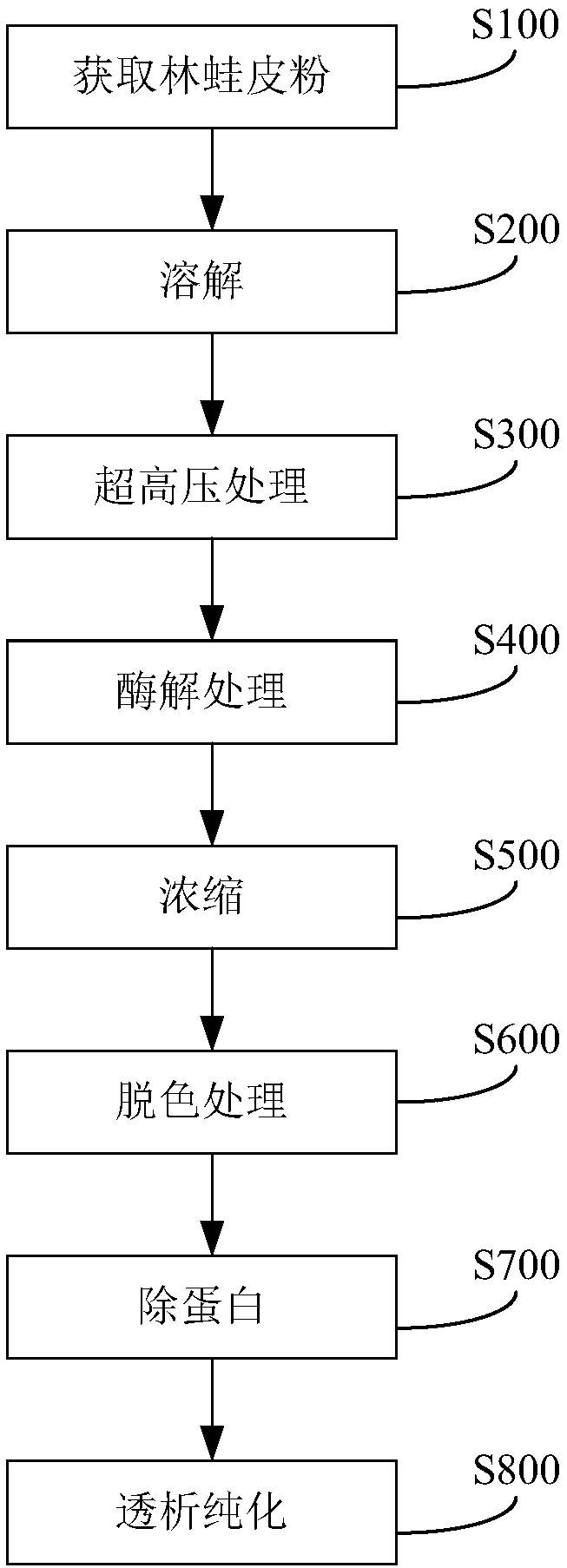

Image

Examples

Embodiment 1

[0098] (1) Obtain freshly stripped Rana skin, remove subcutaneous tissue and adhesions, wash, dry at room temperature, and pulverize to obtain Rana skin powder;

[0099] (2) Dissolution: Weigh 10 g of Rana skin powder and dissolve it in 100 ml of distilled water, stir with a magnetic stirrer for 6 hours, and put it in a refrigerator at 4°C overnight to fully dissolve it.

[0100] (3) Ultrasonic treatment: the dissolved Rana skin was made into a solution, and treated with ultrasonic waves, specifically at 20KHz-35KHz, 100W-300W, for 20min-30min.

[0101] (4) Ultra-high pressure treatment: put the solution after ultrasonic treatment in an ultra-high pressure container, start the high-pressure oil pump, keep it at 200-400Mpa for 2-5min at this pressure, then quickly open the valve controlling the high-pressure oil circuit, The pressure is released within 2s, and the sample after ultra-high pressure treatment is ready for use.

[0102] (5) Enzymatic hydrolysis: adopt protease ste...

Embodiment 2

[0110] (1) Obtain freshly stripped Rana skin, remove subcutaneous tissue and adhesions, wash, dry at room temperature, and pulverize to obtain Rana skin powder;

[0111] (2) Dissolution: Weigh 10g of Rana skin powder and dissolve it in 150ml of distilled water, stir it with a magnetic stirrer for 8 hours, and put it in a refrigerator at 4°C overnight to fully dissolve it.

[0112] (3) Ultrasonic treatment: the dissolved Rana skin was made into a solution, and treated with ultrasonic waves, specifically at 20KHz-35KHz, 100W-300W, for 20min-30min.

[0113] (4) Ultra-high pressure treatment: put the solution after ultrasonic treatment in an ultra-high pressure container, start the high-pressure oil pump, keep it at 200-400Mpa for 2-5min at this pressure, then quickly open the valve controlling the high-pressure oil circuit, The pressure is released within 2s, and the sample after ultra-high pressure treatment is ready for use.

[0114] (5) Enzymolysis: adopt protease step-by-ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com