Graphene modified inorganic material, preparation method and application

A technology of inorganic materials and graphene, applied in inorganic chemistry, chemical instruments and methods, silicon compounds, etc., can solve the problems that the performance of composite materials is affected by the degree of dispersion, time-consuming, high reduction temperature, etc., to achieve excellent composite effect, use The effect of long life and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

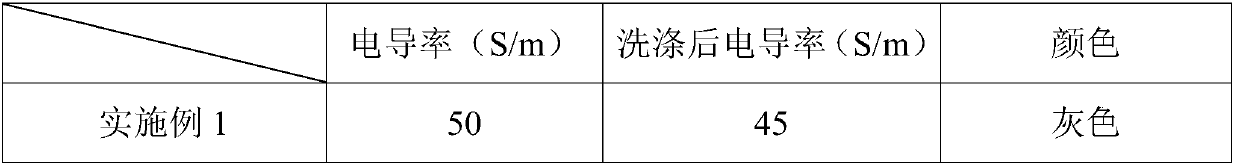

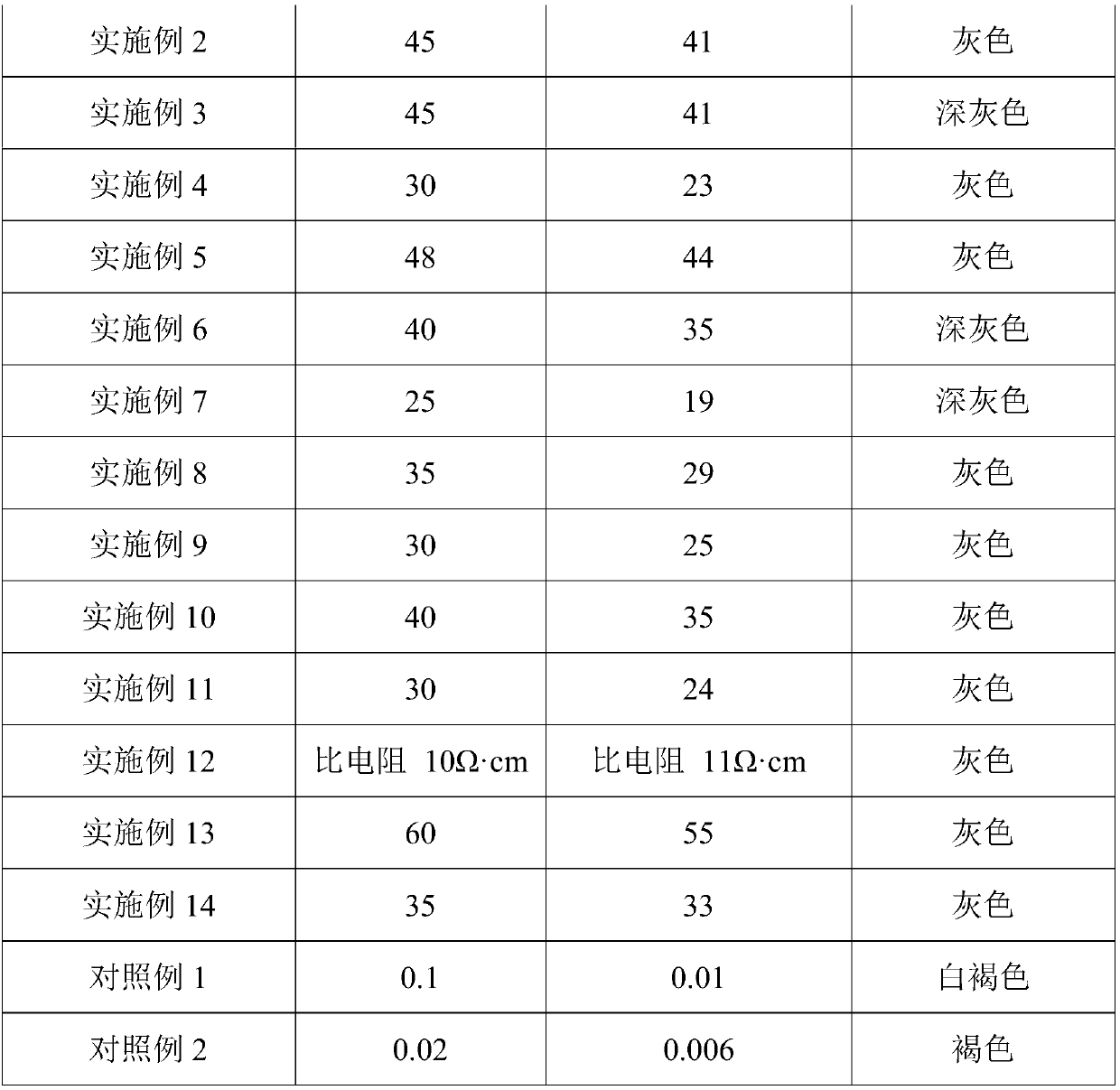

Examples

Embodiment 1

[0083] A method for preparing graphene composite mica sheets, comprising the steps of:

[0084] (1) Take 500g of mica flakes, soak them in 2L of deionized water, stir to remove surface impurities, and heat them up while stirring. The heat treatment temperature is 95°C, and the heat treatment time is 24 minutes;

[0085] (2) Take 2.5g of graphene oxide, disperse the graphene oxide in 500mL of ethanol to water solution with a volume ratio of 1:1, and use an ultrasonic pulverizer with a power of 1000W to supersonicate the graphene oxide solution for 10 minutes to obtain uniformly dispersed graphite oxide olefin dispersion;

[0086] (3) Take out the mica sheet in step (1), put it into the graphene oxide dispersion in step (2), stir the mixed solution slowly and raise the temperature to 98°C for compounding, the compounding time is 40min, and the compounded material dispersion;

[0087] (4) Filter the composite material dispersion obtained in step (3), take out the filter residue...

Embodiment 2

[0093] The difference with embodiment 1 is only: the heat treatment temperature in step (1) is 95 ℃;

[0094] Example 2 obtains mica flakes with reduced graphene loaded on the surface.

Embodiment 3

[0096] The difference with embodiment 1 is only: the weight of graphene oxide is 50g in the step (2);

[0097] Example 3 obtains mica flakes with surface-loaded reduced graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com