Automatic recovery processing device and method for plastic water bottle

An automatic recycling and processing device technology, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of complex structure, unreliable performance, troublesome recycling operation, etc., and achieve the effect of simple recycling operation and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

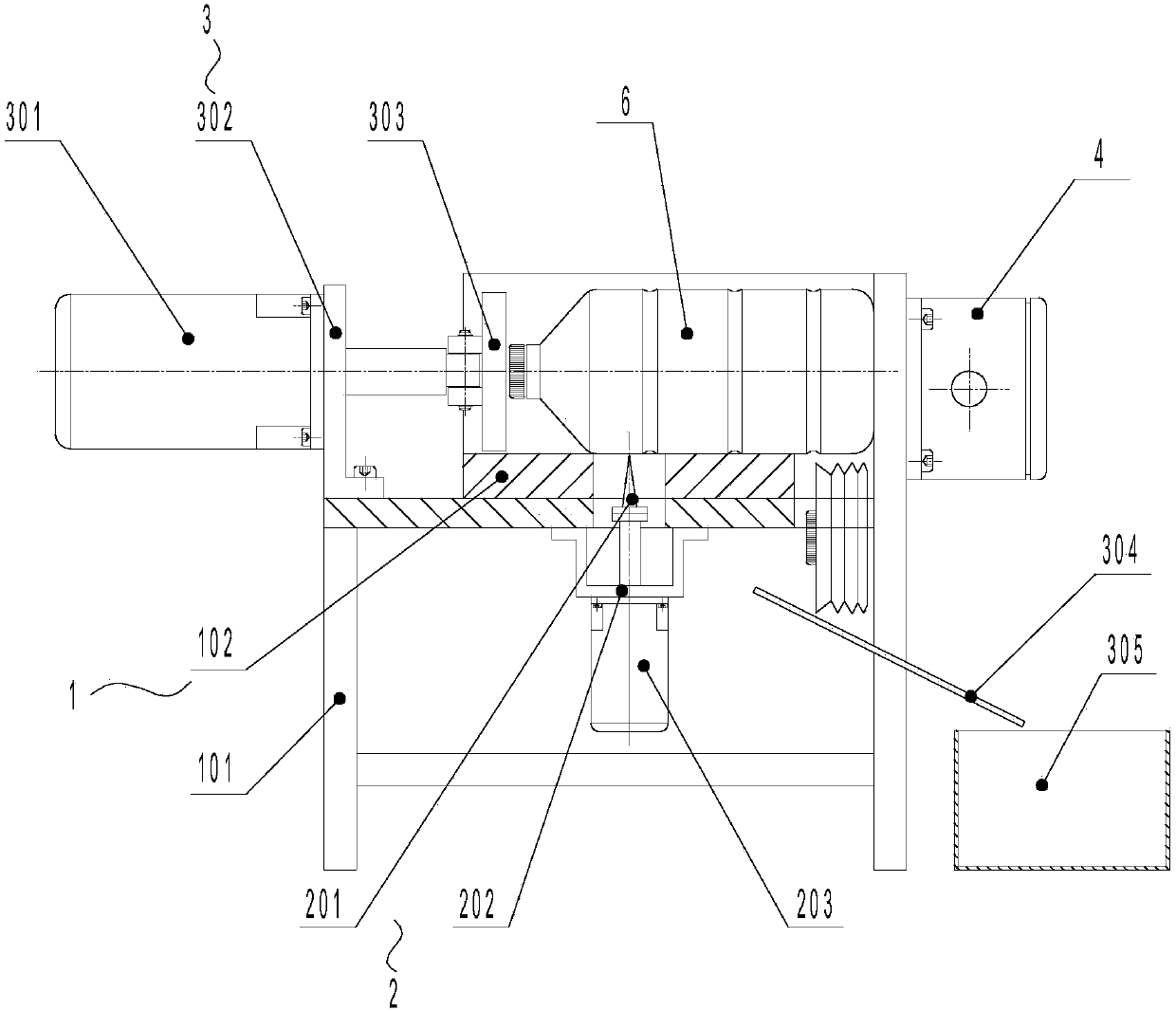

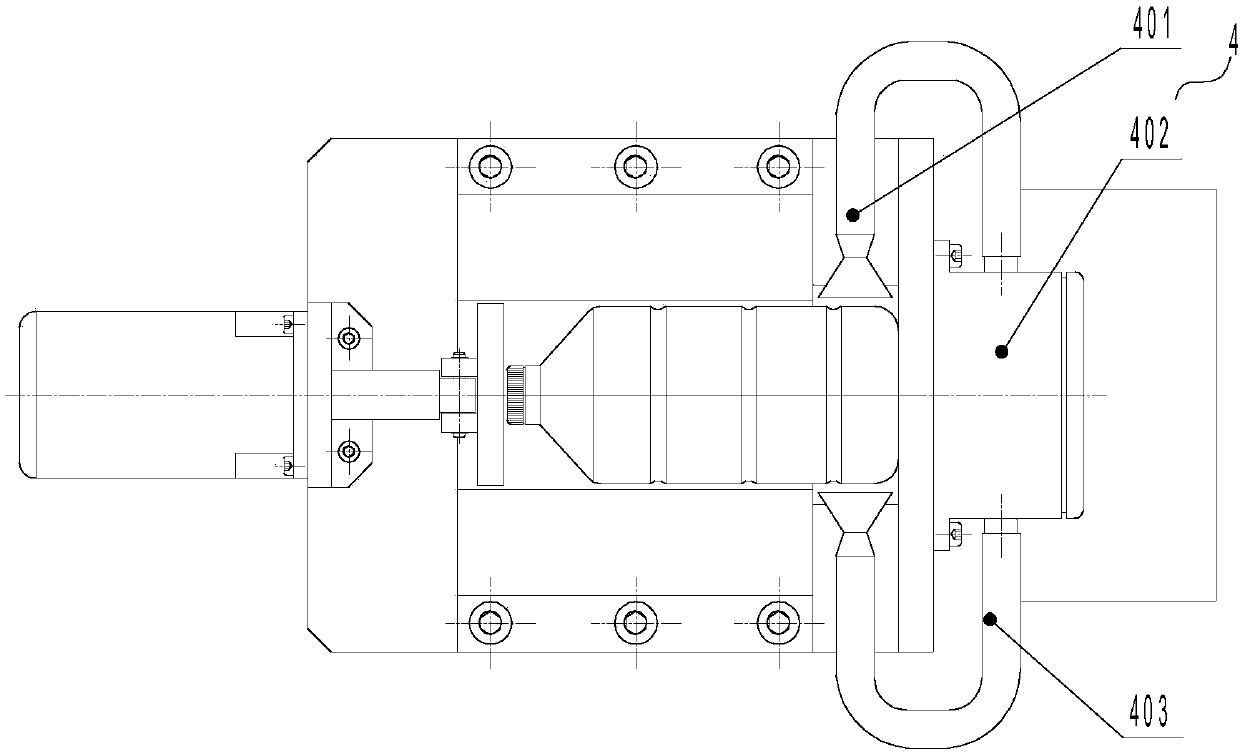

[0044] An automatic recycling and processing device for plastic water bottles, comprising a support mechanism 1, a drainage and exhaust mechanism 2 respectively installed on the support mechanism 1, a compression mechanism 3, a heating and shaping mechanism 4 and a control mechanism, and the plastic water bottles 6 to be recycled are fixed on the support On the mechanism 1, the drainage and exhaust mechanism 2 is connected to the bottom of the plastic water bottle 6, and the compression mechanism 3 and the heating and setting mechanism 4 are respectively connected to both sides of the plastic water bottle 6. The support mechanism 1, the drainage and exhaust mechanism 2, the compression mechanism 3. The heating and shaping mechanism 4 is respectively connected with the control mechanism. in:

[0045] Described support mechanism 1 comprises support frame 101, plastic water bottle support fixed frame 102, and plastic water bottle support fixed frame 102 is installed on the suppor...

Embodiment 2

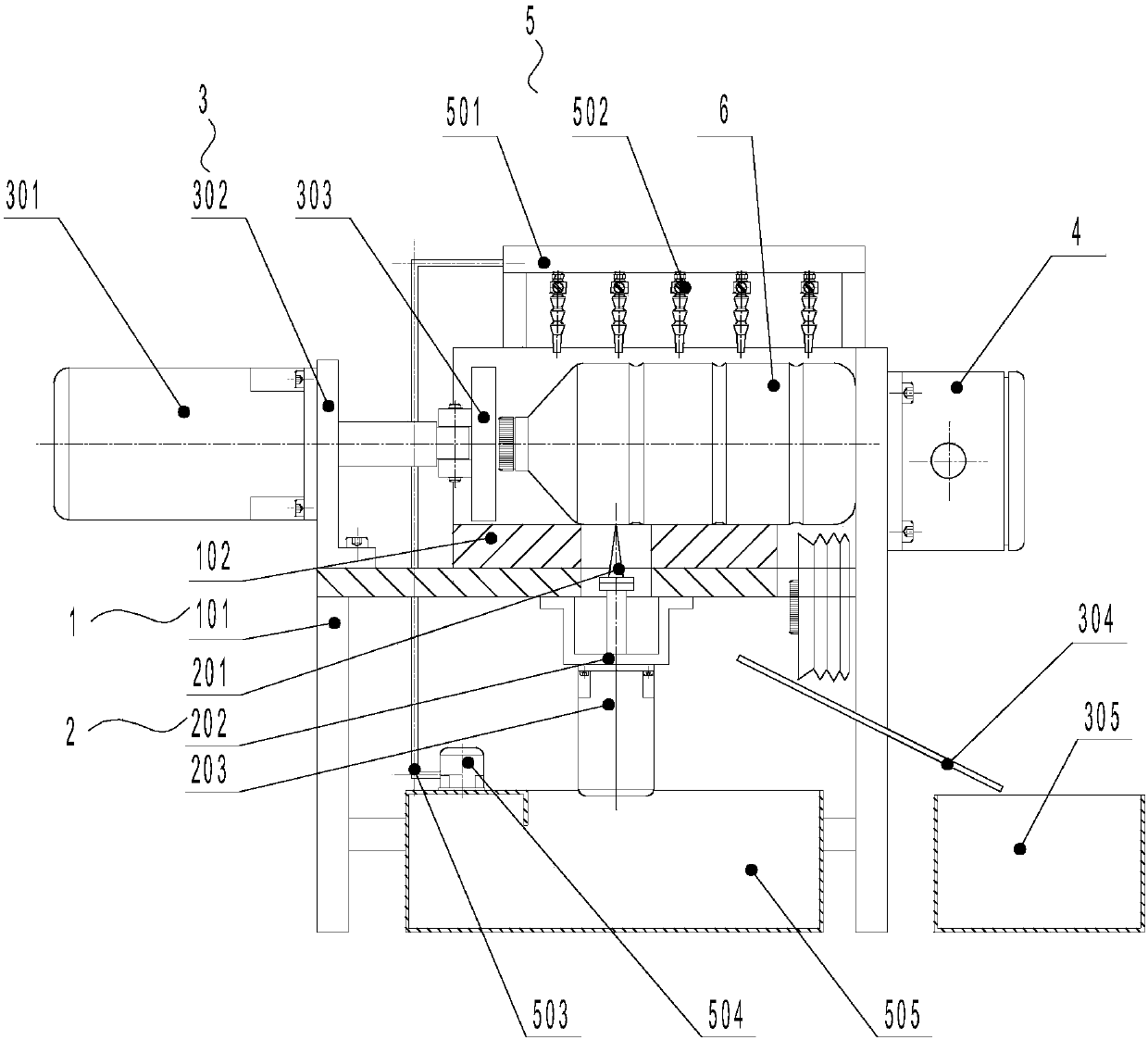

[0050] A plastic water bottle automatic recycling processing device, the basic structure of the device is the same as that of Embodiment 1, the difference is that the plastic water bottle automatic recycling processing device also includes a plastic water bottle cleaning mechanism 5, and the plastic water bottle cleaning mechanism 5 includes a nozzle support Frame 501, shower head 502, water pipe 503, water pump 504, water tank 505; Described shower head 502 is installed on the shower head support frame 501, and the nozzle of shower head 502 supports the plastic water bottle 6 in the plastic water bottle support fixed frame 102; Shower head support frame 501 Installed on the support frame 101, one end of the water pipe 503 is connected with each nozzle 502 on the nozzle support frame 501, and the other end of the water pipe 503 is connected with the output end of the water pump 504, and the water pump 504 is installed on the water tank 505; The spray head 502 and the water pump...

Embodiment 3

[0059] A plastic water bottle automatic recycling processing method realized by the plastic water bottle automatic recycling processing device described in the first embodiment, the method is to place the discarded plastic water bottle on the plastic water bottle supporting and fixing frame of the plastic water bottle automatic recycling processing device, and the plastic water bottle supports The fixing frame automatically fixes the plastic water bottle, and at the same time, the drainage needle bar of the drainage and exhaust mechanism at the bottom of the plastic water bottle punctures the plastic water bottle under the action of the drainage cylinder, and discharges the air and waste water in the plastic water bottle, and the control system then starts the compression The mechanism compresses the plastic water bottle into a cake shape, and keeps the compressed state not to loosen. At the same time, it starts the heating and setting mechanism to heat and shape the compressed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap