Engine cover with good sound-insulating and high-temperature-resisting property

An engine cover, high temperature resistance technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve problems such as affecting the engine cover's protection effect on the engine, easy deformation of plastic materials, and inability to isolate noise. Compression resistance, reasonable structure design, and the effect of blocking heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

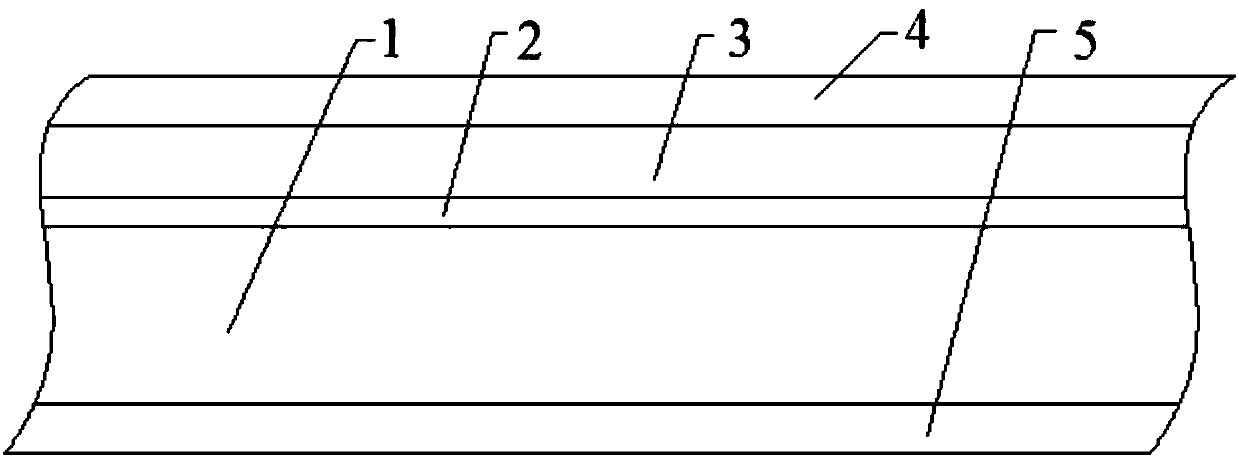

[0014] An engine cover with good sound insulation and high temperature resistance as shown in the accompanying drawing, the cover includes: a honeycomb composite material layer 1, a soundproof aluminum film bonded to the upper part of the honeycomb composite material layer 1 by a high temperature resistant adhesive Layer 2, the glass fiber fabric resin composite material layer 3 bonded to the upper part of the soundproof aluminum film layer 2 by a high temperature resistant adhesive, respectively bonded to the top of the glass fiber fabric resin composite material layer 3 and the honeycomb composite layer by a high temperature resistant adhesive An upper nonwoven layer 4 and a lower nonwoven layer 5 at the bottom of the material layer 1 .

[0015] It is further defined that the honeycomb holes of the honeycomb composite material layer 1 in the above technical solution are axially arranged along the longitudinal direction, and the thickness of the honeycomb composite material la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com