Full-automatic template high-speed sewing equipment

A fully automatic, template technology, used in sewing equipment, sewing machine components, program-controlled sewing machines, etc., can solve the problems of poor stability and reliability, difficult maintenance of sewing machines, and thread take-up levers Great difficulty, increasing smoothness of movement, and maintaining stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

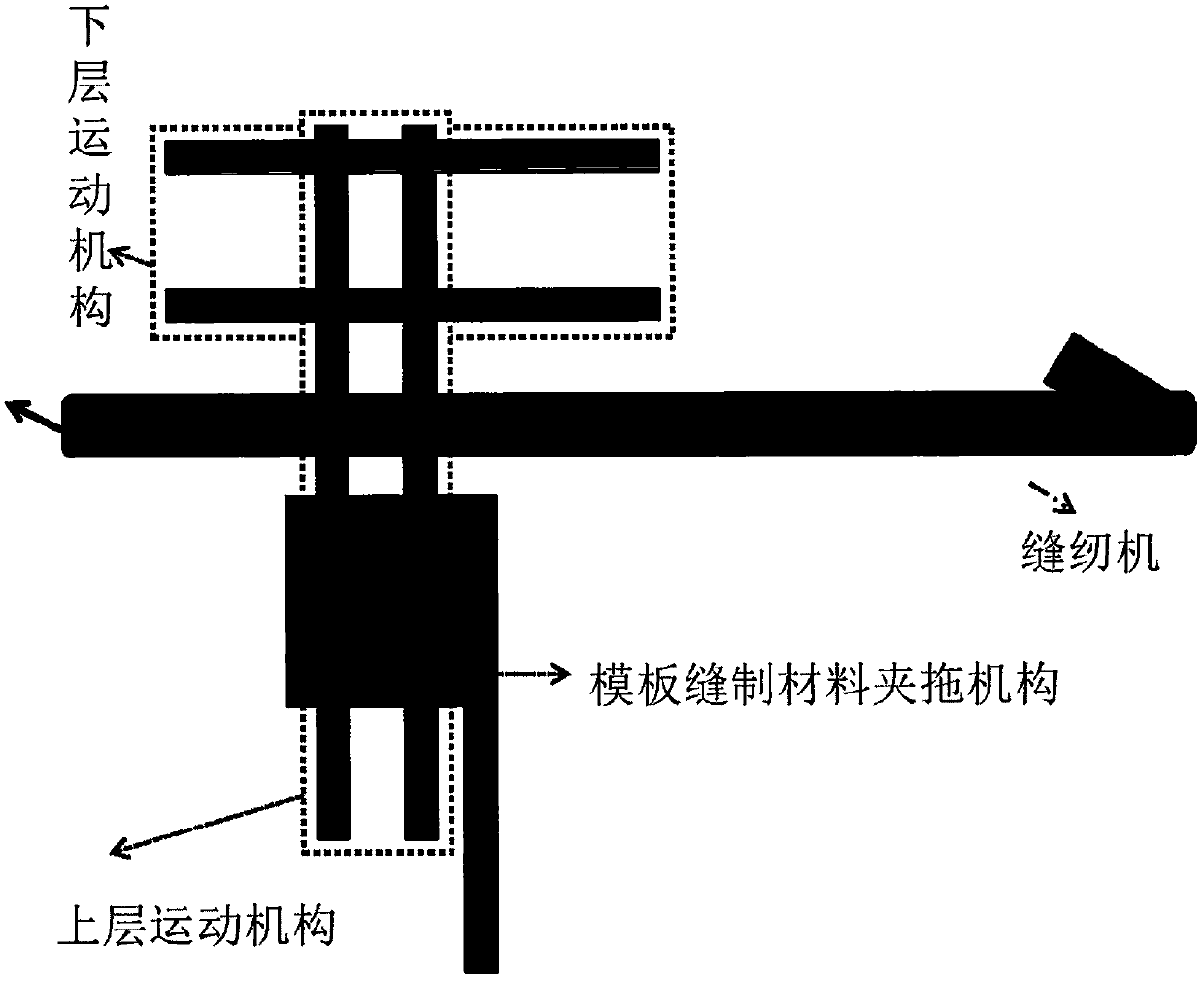

[0008] Such as figure 1 As shown, a fully automatic template high-speed sewing equipment includes a sewing machine, a template sewing material clamping and dragging mechanism, an upper-layer moving mechanism, and a lower-layer moving mechanism. The sewing machine adopts a double-moving knife thread-cutting structure. The sewing machine performs independent real-time motion control on the presser foot through a motor connected to a crank connecting rod structure. The sewing machine adjusts the tightness of the sewing thread in real time through an electronically controllable thread elastic mechanism according to the characteristics of the sewing material, thread and sewing speed. The modularization of the upper layer motion mechanism and the lower layer motion mechanism is independent of the sewing machine. The upper and lower moving mechanisms are clamped on the linear optical axis by roller bearings with U-shaped grooves or V-shaped grooves and are driven by an adjustable e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com