Gene-induced suspending liquid fertilizer and preparation method thereof

A technology of gene induction and suspending liquid, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of poor disease resistance, soil impact, etc., and achieve the effects of reducing losses, transporting finished products, and no discharge of three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

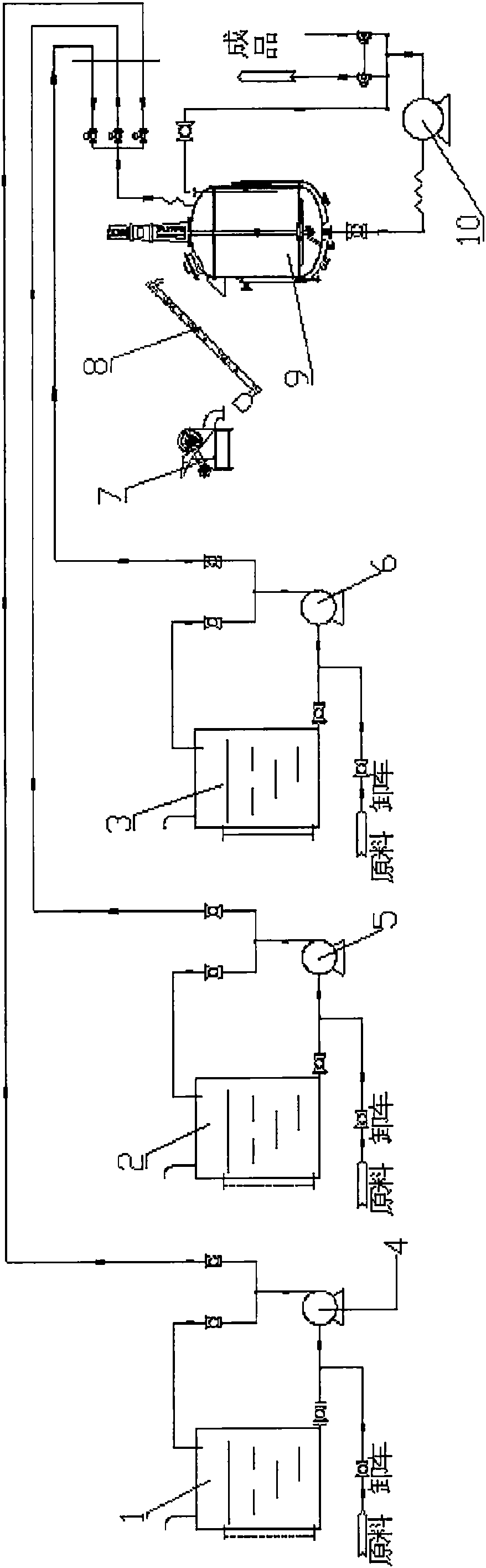

Method used

Image

Examples

Embodiment 1

[0028] In the embodiment of the present invention, a gene-induced suspension liquid fertilizer is composed of the following raw materials in parts by weight: 3 parts of gene-induced components, 5 parts of humic acid, 35 parts of nitrogen, phosphorus and potassium compound fertilizers, 5 parts of ammonium polyphosphate, 15 parts of water, 1 part of suspending agent, and 1 part of defoamer, wherein the gene induction component is composed of alginic acid and oligomeric acid.

[0029] The preparation method of the gene-inducible suspension liquid fertilizer comprises the following steps:

[0030] In the first step, the NPK compound fertilizer is mixed and pulverized to 200 mesh in a pulverizer.

[0031] In the second step, water and ammonium polyphosphate are added into the shear emulsifier, the rotational speed of the shear emulsifier is 1000r / min, and the shear treatment time is 10min.

[0032] In the third step, put the suspending agent into the shear emulsifier, and the shea...

Embodiment 2

[0036] In the embodiment of the present invention, a gene-induced suspension liquid fertilizer is composed of the following raw materials in parts by weight: 15 parts of gene-induced components, 25 parts of humic acid, 55 parts of nitrogen, phosphorus and potassium compound fertilizer, 25 parts of ammonium polyphosphate, 35 parts of water, 5 parts of suspending agent, and 3 parts of defoamer, wherein the gene induction component is composed of alginic acid and oligomeric acid.

[0037] The preparation method of the gene-inducible suspension liquid fertilizer comprises the following steps:

[0038] In the first step, the NPK compound fertilizer is mixed and pulverized to 200 mesh in a pulverizer.

[0039] In the second step, water and ammonium polyphosphate are added to the shearing emulsifier, the rotational speed of the shearing emulsifier is 6000r / min, and the shearing treatment time is 30min.

[0040] In the third step, the suspending agent is put into the shear emulsifier...

Embodiment 3

[0044] In the embodiment of the present invention, a gene-induced suspension liquid fertilizer is composed of the following raw materials in parts by weight: 5 parts of gene-induced components, 10 parts of humic acid, 40 parts of nitrogen, phosphorus and potassium compound fertilizer, 10 parts of ammonium polyphosphate, 20 parts of water, 2 parts of suspending agent, and 1 part of defoamer, wherein the gene induction component is composed of alginic acid and oligomeric acid.

[0045] The preparation method of the gene-inducible suspension liquid fertilizer comprises the following steps:

[0046] In the first step, the NPK compound fertilizer is mixed and pulverized to 200 mesh in a pulverizer.

[0047] In the second step, water and ammonium polyphosphate are added into the shear emulsifier, the rotational speed of the shear emulsifier is 3000r / min, and the shear treatment time is 15min.

[0048] In the third step, put the suspending agent into the shearing emulsifier, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com