NiCuZn Ferrite material and preparation method and application thereof

A technology of ferrite materials and main materials, which is applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, waveguide devices, etc., can solve the problems of high ferromagnetic resonance line width, easy to appear porous structure, low density, etc. achieve performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a kind of preparation method of above-mentioned NiCuZn ferrite material, it comprises:

[0027] The main material is mixed with deionized water and ball milled for the first time to obtain a slurry.

[0028] Among them, in a preferred embodiment of the present invention, the main material and deionized water are mixed at a weight ratio of 1:1.5 and then ball milled for the first time. Under this ratio, dust is effectively avoided, waste of raw materials is avoided, and Fe 2 o 3 , CuO, ZnO and NiO are fully mixed and uniform, and the solid phase reaction is sufficient during pre-burning. Preferably, the first ball milling time is 1-4 hours, so that the main ingredients are fully mixed and even. At the same time, deionized water is used to effectively avoid the introduction of impurities and prevent the performance of the final NiCuZn ferrite material from being affected.

[0029] Preferably, in a preferred embodiment of the present ...

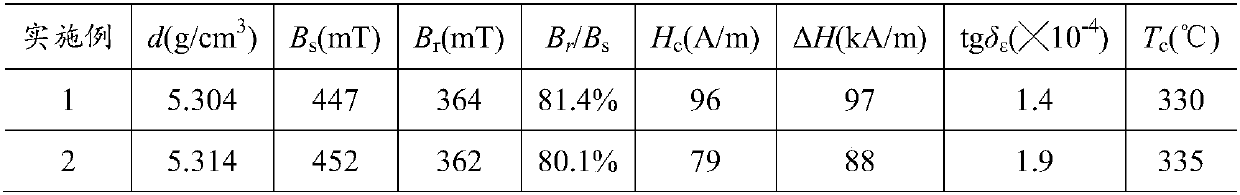

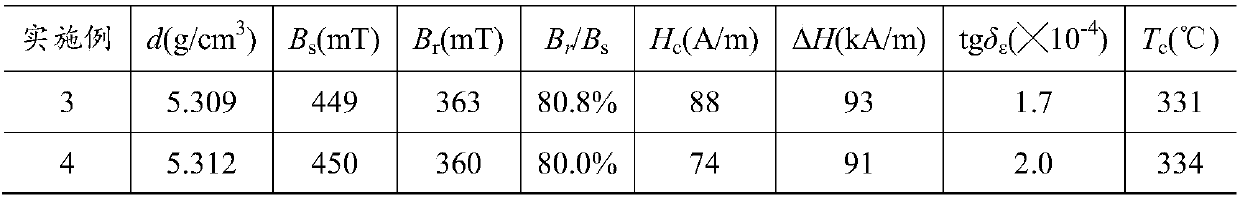

Embodiment 1

[0048] A kind of NiCuZn ferrite material, it is made by following method:

[0049] After the main material is mixed with deionized water, steel balls are used in the ball mill for the first time for 3 hours to mix the powder evenly to obtain a slurry. After drying, it is placed in a pre-calcined furnace and kept at 900°C for 2.5 hours to obtain the pre-calcined main material. material.

[0050] The calcined main material is mixed with the dopant to obtain the first mixed material.

[0051] The first mixed material is ball-milled for the second time in a ball mill with zirconium balls for 6 hours to a particle size of 0.8-1.2 μm, then mixed evenly with the binder, granulated, pressed into a blank, and placed in a sintering furnace Debinding, heat preservation at 1040°C for 4 hours under air atmosphere.

[0052] Among them, the main material contains 49mol% Fe in terms of oxide content 2 o 3 , 6mol% of CuO, 19.5mol% of ZnO, 25.5mol% of NiO; the dopant contains 0.15wt% of Bi ...

Embodiment 2

[0054] A kind of NiCuZn ferrite material, it is made by following method:

[0055] After the main material is mixed with deionized water, steel balls are used in the ball mill for the first time for 3 hours to mix the powder evenly to obtain a slurry. After drying, it is placed in a pre-calcined furnace and kept at 900°C for 2.5 hours to obtain the pre-calcined main material. material.

[0056] The calcined main material is mixed with the dopant to obtain the first mixed material.

[0057] The first mixed material is ball-milled for the second time in a ball mill with zirconium balls for 6 hours to a particle size of 0.8-1.2 μm, then mixed evenly with the binder, granulated, pressed into a blank, and placed in a sintering furnace Debinding and heat preservation at 1080°C for 4 hours in an air atmosphere.

[0058] Among them, the main material contains 49mol% Fe in terms of oxide content 2 o 3 , 6mol% of CuO, 19.5mol% of ZnO, 25.5mol% of NiO; the dopant contains 0.15wt% of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com