Redundant driving parallel machine tool executing mechanism with singularity-avoiding characteristic

An actuator and redundant technology, which is applied in the field of redundantly driven parallel machine tool actuators, achieves the effects of high rigidity, fast dynamic response, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A redundantly driven parallel machine tool actuator with singular avoidance characteristics of the present invention is further described in detail in conjunction with the accompanying drawings and embodiments.

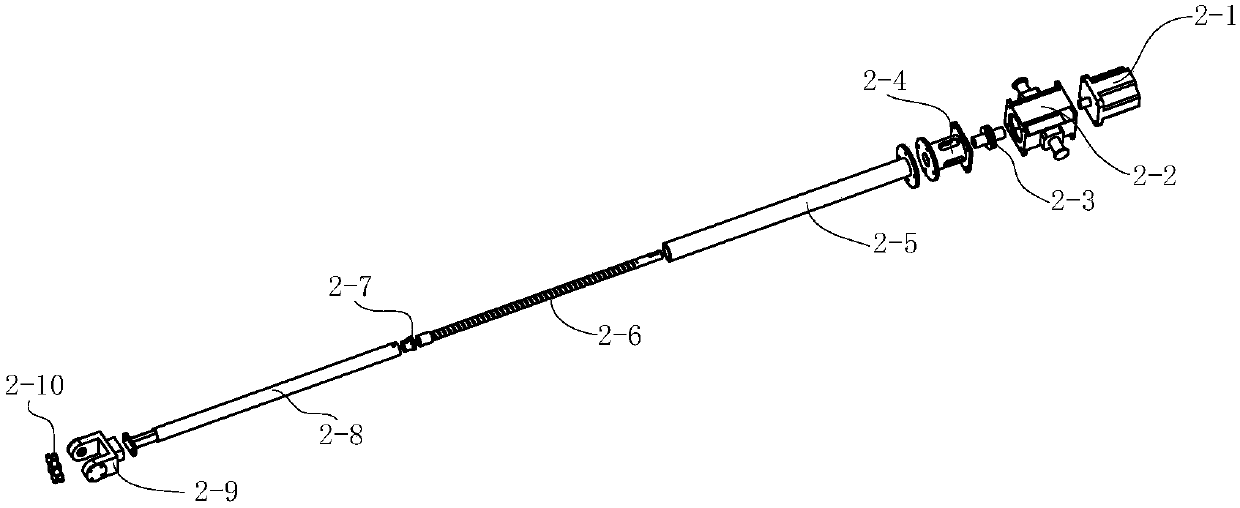

[0029] Such as figure 1 A schematic diagram of the overall structure of a redundant drive parallel machine tool actuator with singularity avoidance shown, which includes a fixed platform 1, a first drive branch chain 2, a second drive branch chain 3, a redundant drive branch chain 4, and a motion platform And the spindle cutter head assembly 5.

[0030] Such as figure 2As shown, the fixed platform 1 is equipped with a fixed bracket 1-1, the first drive branch chain support plate 1-2-1, the second drive branch chain support plate 1-2-2, the third drive branch chain support plate 1 -2-3 and the fourth drive branch chain support plate 1-2-4 are respectively fastened to the fixed bracket 1-1 through bolts, the first redundant drive branch chain support plate 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com