Multi-rotation-direction reaction kettle

A reaction kettle and tank body technology, which is applied in the field of multi-rotation reaction kettles, can solve the problems of discounting the mixing and stirring effect of products, affecting the stirring effect of the reaction kettle, etc., and achieves efficient and stable power transmission process, ingenious overall structure design, and increased up and down tossing. the effect of the ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

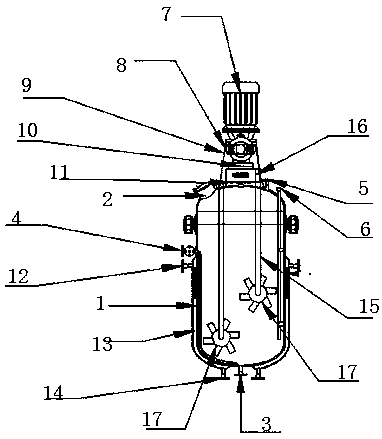

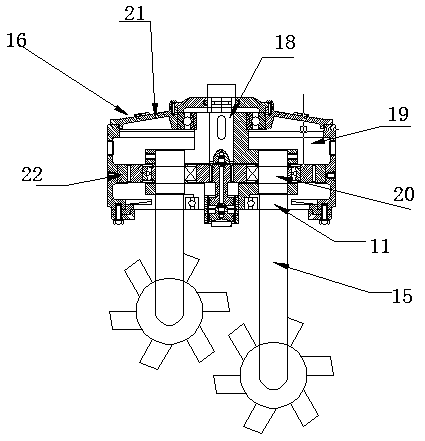

[0019] Embodiment 1: see Figure 1-Figure 2, a multi-rotation reaction kettle, the multi-rotation reaction kettle includes a tank assembly, a power assembly, a heating assembly and a stirring assembly; the power assembly is installed above the tank assembly; the heating assembly is installed on the tank assembly on the outer wall; the stirring assembly is installed inside the tank assembly, and the top is connected with the power assembly. The design structure is simple and clear, the components are closely connected and do not affect each other, the required parts are easy to replace, and it is easy to maintain the product during use in the future. The tank body components include tank body 1, manhole 2, outlet Liquid port 3, liquid inlet 4, pressure relief valve 5 and pressure outlet pipe 6; the manhole is installed on the left side of the top of the tank; the liquid inlet is located at the upper left side of the tank; the liquid outlet is located at the top of the tank The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com