Friction nanometer generator, preparation method thereof and application thereof

A technology of nano generators and generators, applied in the direction of friction generators, manufacturing electric generators, chemical instruments and methods, etc., can solve the problems of high manufacturing costs, limited applications, complicated preparation processes, etc., and achieve low price, wide field The effect of a wide range of occasions and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

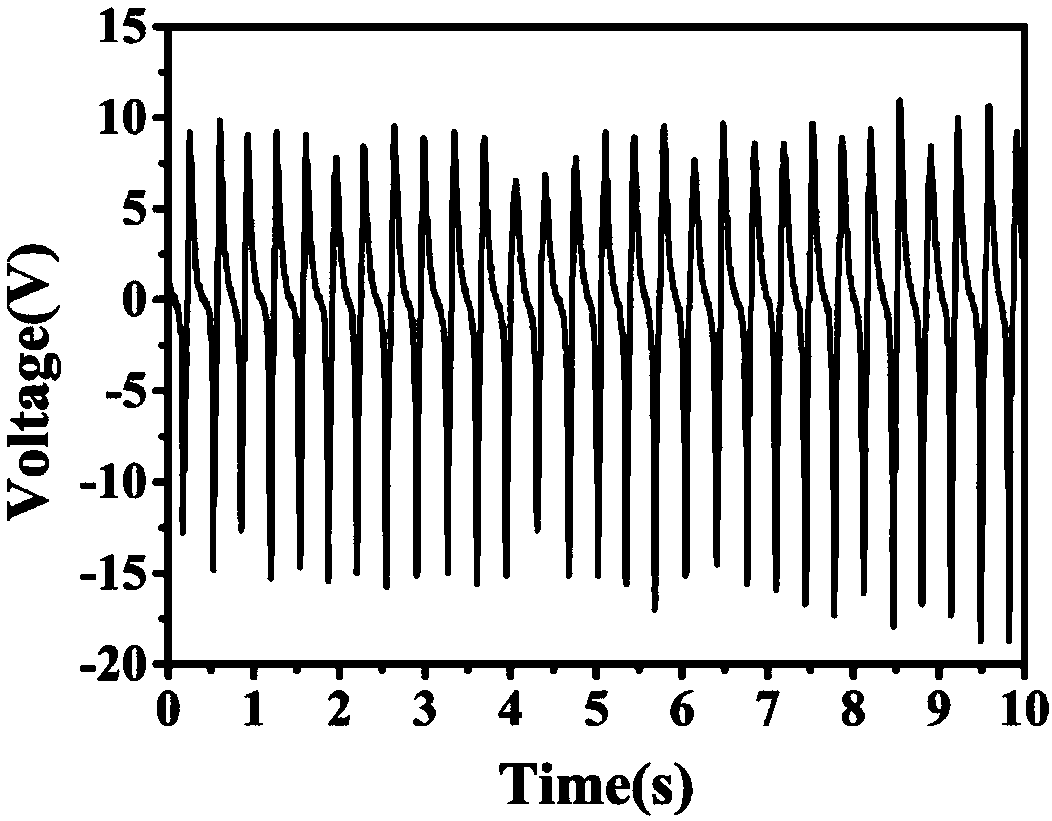

Image

Examples

Embodiment 1

[0060] A preparation method of a triboelectric nanogenerator, said preparation method comprising the following contents:

[0061] (1) Preparation of solution:

[0062] 5 g of ethyl cellulose was dissolved in a mixed solution of 30 ml of dichloromethane and 15 ml of absolute ethanol, and stirred for 5 h until the vaguely dissolved cellulose was fully dissolved to obtain a pale yellow ethyl cellulose solution;

[0063] Mix polydimethylsiloxane (PDMS) and curing agent (prepolymer with vinyl side chains) at a mass ratio of 3:1, and stir for 5 minutes until the two are fully mixed to obtain a white and transparent product without bubbles. Liquid, that is, the polydimethylsiloxane solution;

[0064] (2) Preparation of polyethylene terephthalate / ethyl cellulose film: the ethyl cellulose solution is spin-coated on a polyethylene terephthalate (PET) sheet as a supporting substrate , placed at room temperature for 5 hours to obtain a transparent polyethylene terephthalate / ethyl cellul...

Embodiment 2

[0080] The nanogenerator of the present embodiment and the preparation method thereof are basically the same as in Example 1, except that:

[0081] During the preparation of ethyl cellulose solution in step (1), the quality of ethyl cellulose is 9g; the volume of dichloromethane is 50ml; the volume of absolute ethanol is 25ml; the stirring time is 6h;

[0082] When preparing polydimethylsiloxane solution, the mass ratio of polydimethylsiloxane (PDMS) and curing agent (prepolymer with vinyl side chain) is 1:1;

[0083] The standing time described in step (2) is 5h;

[0084] The etching time described in step (3) is 60s;

[0085] The drying temperature described in step (4) is 60° C., and the drying time is 15 minutes;

[0086] The drying temperature in step (5) is 120°C; the drying time is 3h;

[0087] The etching time described in step (6) is 300s;

[0088] The drying temperature in step (7) is 60° C.; the drying time is 15 minutes.

[0089] The friction nanogenerator obt...

Embodiment 3

[0091] The generator of the present embodiment and the preparation method thereof are basically the same as in Embodiment 1, except that:

[0092] The friction nanogenerator obtained by the preparation method of this example has a thickness of 78 μm and a mass per unit area of 5 mg.cm -2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com