Bowl-shaped carbon material and preparation method thereof, and point-line-plane three-phase composite conductive paste

A technology of composite conductive and carbon materials, used in circuits, electrical components, battery electrodes, etc., can solve the problem of not being able to build a three-dimensional conductive network, and achieve the effect of improving performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

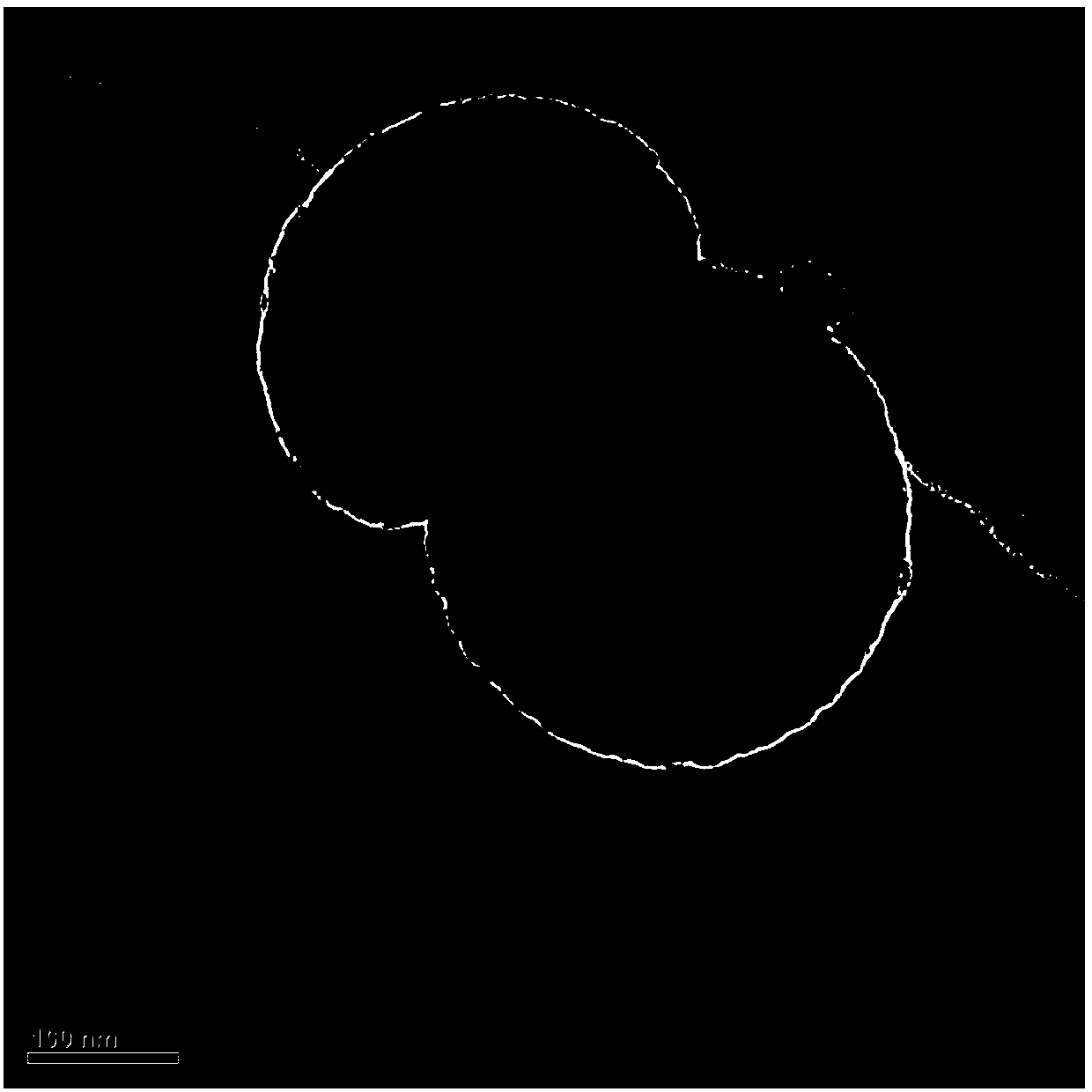

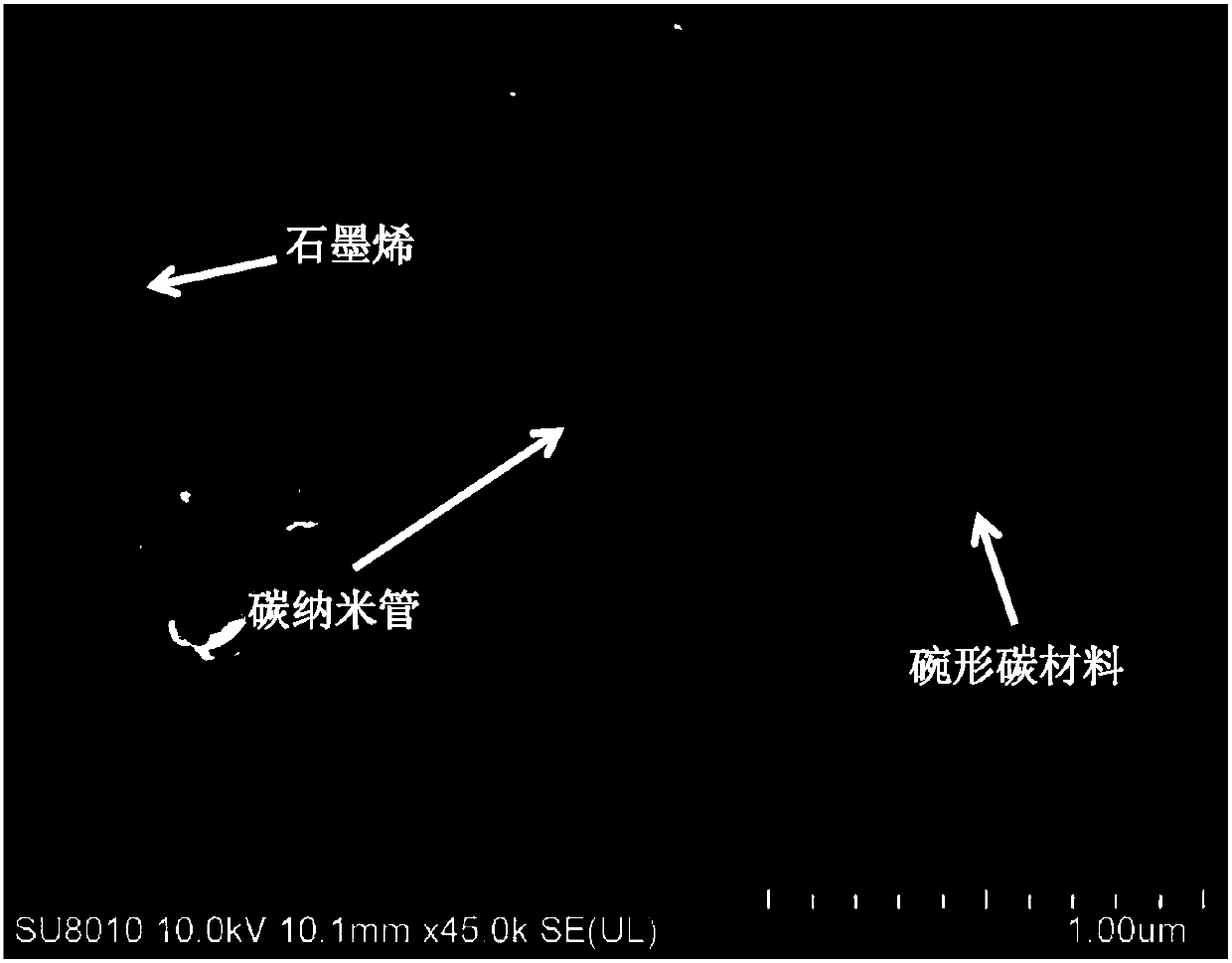

[0045] The present embodiment provides a kind of preparation method of bowl-shaped carbon material, it comprises the following specific steps:

[0046] (1), Weigh 2.0g block copolymer F127 and 3.0g dopamine hydrochloride and add in the mixed solution of 200mL deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1) successively, then add 5.0mL Mesitylene was dropped into it, and 10.0 mL of ammonia water was added dropwise while stirring at room temperature. After stirring for 2 h, the mixed solution of deionized water and ethanol (the volume ratio of water and ethanol was 0.8:1) was washed several times to remove the active agent. F127;

[0047] (2), uniformly disperse the washed polydopamine particles in a mixed solution of deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1), place in a sealed hydrothermal kettle for hydrothermal reaction, set The oven temperature is 120°C, and the hydrothermal reaction time is 24h;

[0048] (3) ...

Embodiment 2

[0050] The present embodiment provides a kind of preparation method of bowl-shaped carbon material, it comprises the following specific steps:

[0051] (1), Weigh 2.0g block copolymer F127 and 3.0g dopamine hydrochloride and add in the mixed solution of 200mL deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1) successively, then add 5.0mL Mesitylene was dropped into it, and 10.0 mL of ammonia water was added dropwise while stirring at room temperature. After stirring for 2 h, the mixed solution of deionized water and ethanol (the volume ratio of water and ethanol was 0.8:1) was washed several times to remove the active agent. F127;

[0052] (2), uniformly disperse the washed polydopamine particles in a mixed solution of deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1), place in a sealed hydrothermal kettle for hydrothermal reaction, set The oven temperature is 120°C, and the hydrothermal reaction time is 24h;

[0053] (3) ...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of bowl-shaped carbon material, it comprises the following specific steps:

[0056] (1), Weigh 2.0g block copolymer F127 and 3.0g dopamine hydrochloride and add in the mixed solution of 200mL deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1) successively, then add 5.0mL Mesitylene was dropped into it, and 10.0 mL of ammonia water was added dropwise while stirring at room temperature. After stirring for 2 h, the mixed solution of deionized water and ethanol (the volume ratio of water and ethanol was 0.8:1) was washed several times to remove the active agent. F127;

[0057] (2), uniformly disperse the washed polydopamine particles in a mixed solution of deionized water and ethanol (the volume ratio of water and ethanol is 0.8:1), place in a sealed hydrothermal kettle for hydrothermal reaction, set The oven temperature is 120°C, and the hydrothermal reaction time is 24h;

[0058] (3) ...

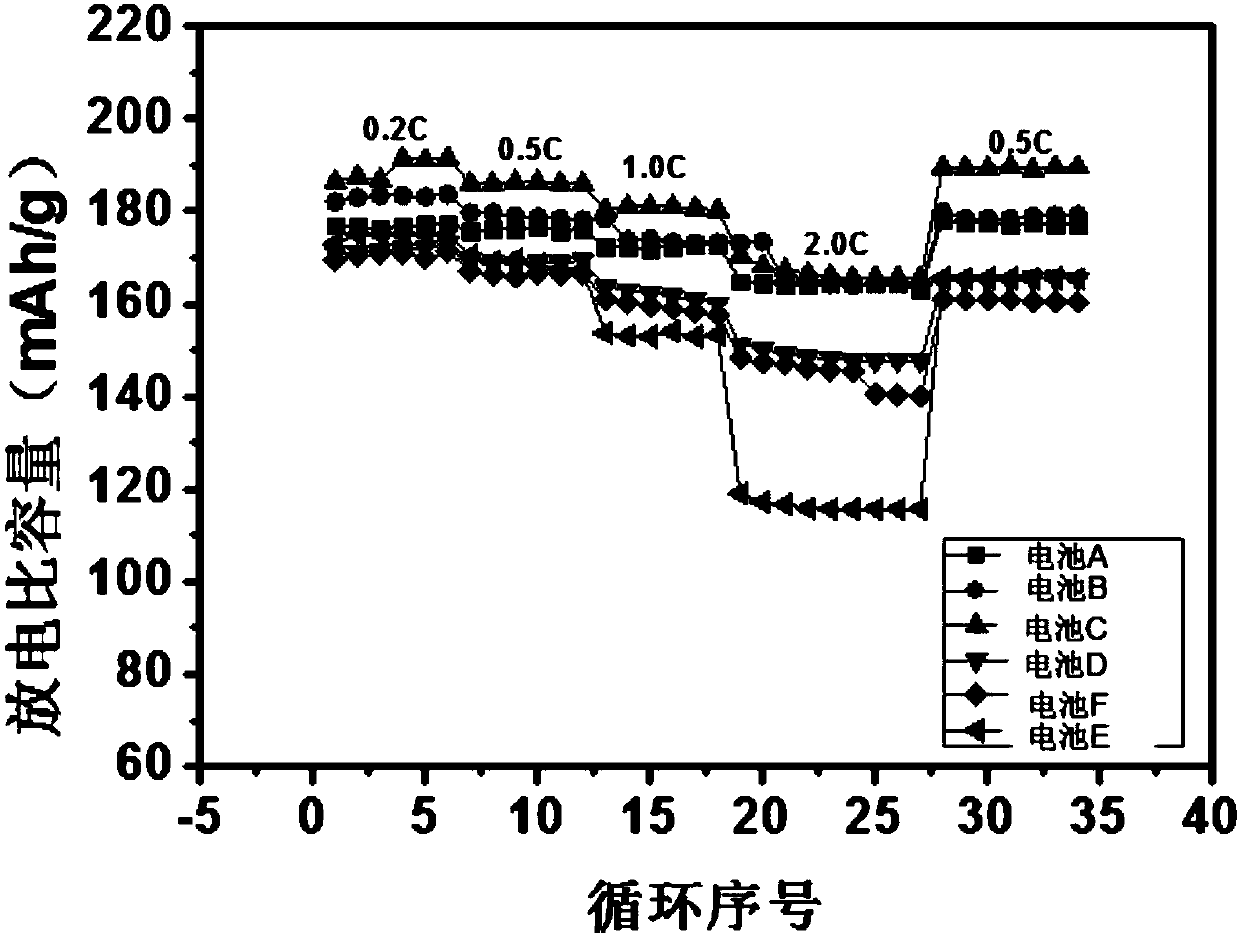

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com