Epitaxial filling method for groove

A filling method and trench technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

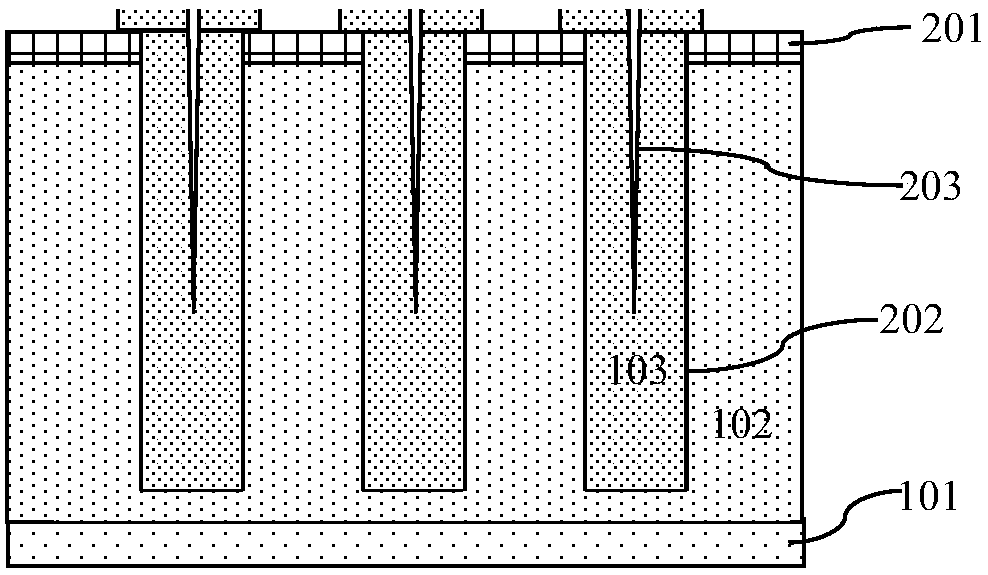

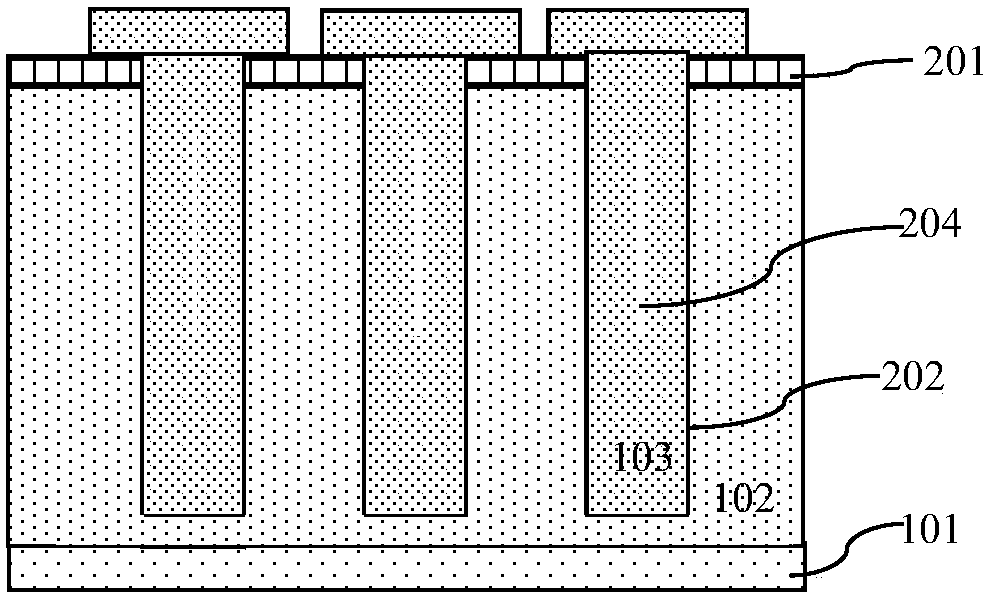

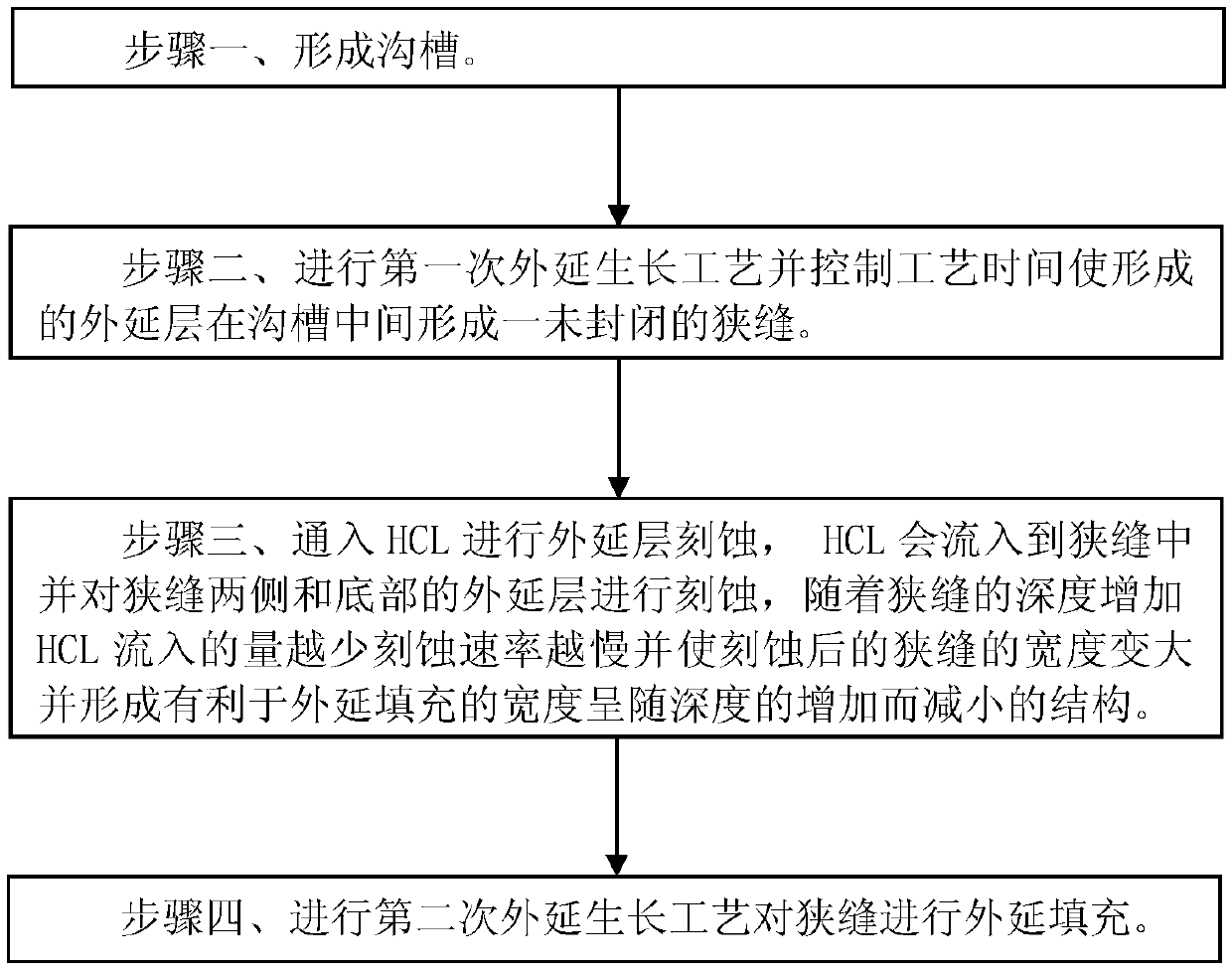

[0026] First introduce the problems that the existing methods have. The method of the embodiment of the present invention has made specific improvements to these technical problems, such as Figure 1A to Figure 1B As shown, it is a schematic diagram of the device structure in each step of the epitaxial filling method of the existing trench; the trench as a superjunction trench is used as an example for illustration, and the existing method includes the following steps:

[0027] Step 1, such as Figure 1A As shown, a semiconductor wafer 101 is provided, and a first conductivity type epitaxial layer 102 is formed on the surface of the semiconductor wafer 101 . Form a hard mask layer 201 on the surface of the epitaxial layer 102 of the first conductivity type, use photolithography to define the formation area of the groove of the super junction, and sequentially apply the hard mask layer in the formation area of the groove 201 and the first conductivity type epitaxial layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com