Cantilever beam impact pendulnm

An impact pendulum and cantilever beam technology, applied in the direction of using one impact force to test the strength of materials, using repeated force/pulse force to test the strength of materials, etc., can solve the impact test that cannot be done at the same time with multiple energy, heavy operation, single function, etc. problems, to achieve the effect of satisfying the use of multi-energy impact, convenient debugging, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

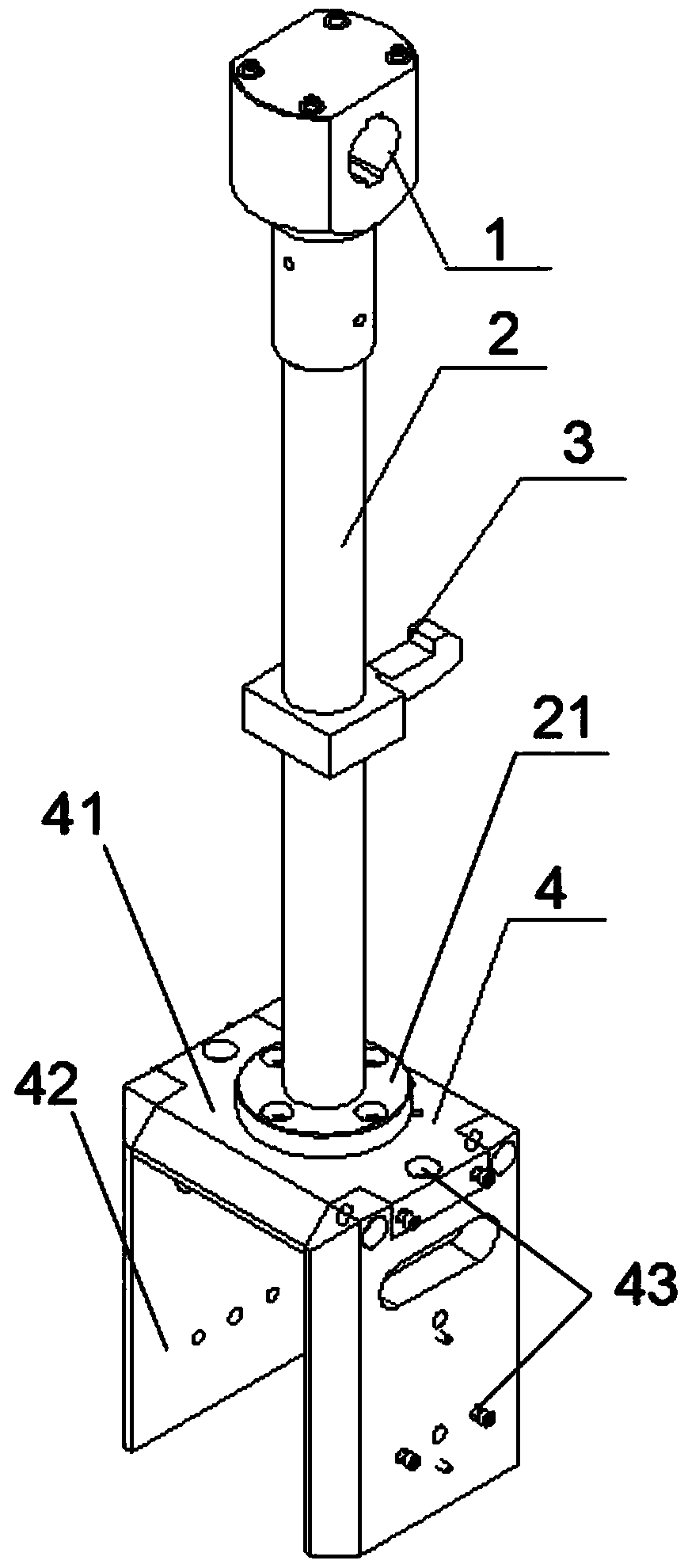

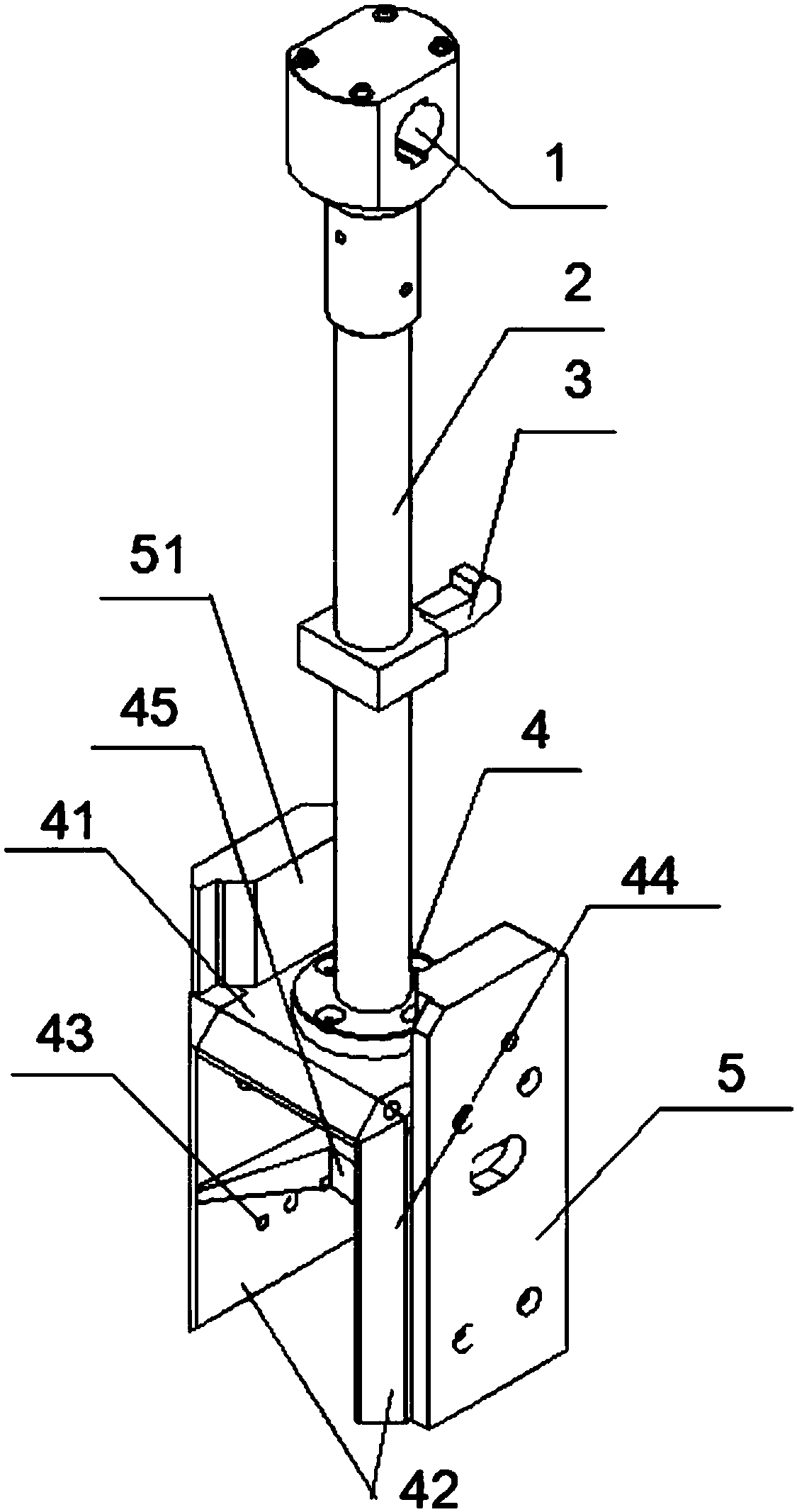

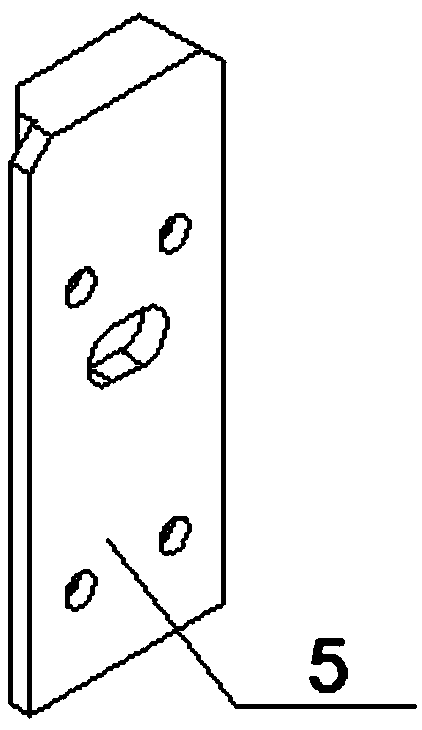

[0025] like figure 1 and figure 2 As shown, the cantilever beam impact pendulum designed in the present invention includes a pendulum suspension mechanism and a pendulum 4, and the pendulum suspension mechanism includes a pendulum 2, a pendulum shaft 1 sleeved on one end of the pendulum and a hook 3 on the pendulum, The pendulum 4 is a U-shaped structure and adopts a U-shaped pendulum arc surface structure 44; the other end of the pendulum 2 is provided with a support seat 21, and the support seat 21 is connected to the center of the pendulum top 41, The top 41 of the pendulum body and the two ends 42 of the pendulum body are all provided with counterweight holes 43 that can be assembled with counterweight weights 5, and the counterweight weights 5 are fitted and connected with the two ends 42 of the pendulum body, and the counterweight weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com