Melt electrostatic spinning device

A spinning device, fusion electrostatic technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of spinning properties, impact, time and cost consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

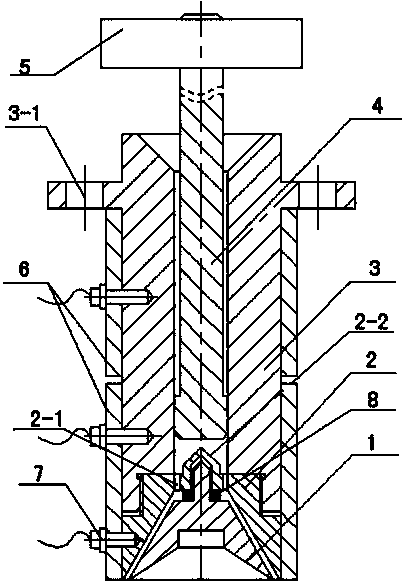

[0046] The spinning device mainly includes a spinning nozzle 1, a spinning nozzle kit 2, a nozzle sleeve 3, a plunger 4, a counterweight plate 5, a heating device 6, a temperature sensor 7, and an elastic sealing ring 8. The spinning nozzle 1 and the spinning nozzle kit 2 and the upper part of the nozzle kit 2 and the nozzle sleeve 3 are all connected by threads, and can be automatically centered through concentricity during installation. The plunger 4 is placed inside the nozzle sleeve 3, Its upper end is connected with the counterweight plate 5 through threads to apply pressure to the melt in the sleeve. The nozzle sleeve 3 is fixed on the spinning frame through uniformly distributed bolt holes 3-1, and the heating device 6 is placed on the nozzle. The periphery of the sleeve 3 can be easily disassembled, the temperature sensor 7 is placed inside the nozzle sleeve, the heating device 6 is connected with the temperature sensor 7 and the temperature control box, and the elastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com