Brazing auxiliary agent for tungsten steel plane welding and welding method thereof

A technology of plane welding and welding method, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc. It can solve the problems of poor weldability and easy seam retention of tungsten carbide, so as to improve welding efficiency and desoldering Less, avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

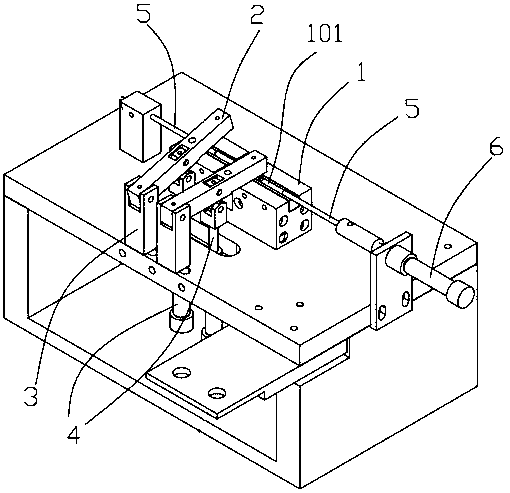

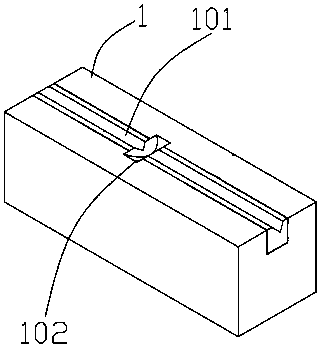

Image

Examples

Embodiment 1

[0027] This embodiment provides a brazing additive for plane welding of tungsten steel, which includes the following components in parts by weight: KF: 48 parts, B 2 O 3 :20 parts, CoCl 2 : 10 parts, composite fluoroborate: 8 parts, composite borate: 10 parts, surfactant: 6 parts, water: 63 parts. Among them, the composite fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate at a mass ratio of 2:1, the composite borate is a mixture of sodium borate and potassium borate at a mass ratio of 1:1, and the surfactant is a perfluoroalkane Base quaternary ammonium salt. Put the above-mentioned components into a crucible according to the proportion and mix them, boil them at a temperature of 150-180°C for 20 minutes, remove the water, and form a paste.

[0028] The brazing aid prepared in this embodiment is uniformly mixed, without delamination, and no visible inclusions, and the brazing aid has good spreadability on the solid silver solder sheet.

[0029] The braz...

Embodiment 2

[0037] This embodiment provides a brazing additive for plane welding of tungsten steel, which includes the following components in parts by weight: KF: 45 parts, B 2 O 3 :15 parts, CoCl 2 : 12 parts, composite fluoroborate: 10 parts, composite borate: 12 parts, surfactant: 9 parts, water: 52 parts. Among them, the composite fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate at a mass ratio of 3:1, the composite borate is a mixture of sodium borate and potassium borate at a mass ratio of 1:1, and the surfactant is a perfluoroalkane 基amine. Put the above-mentioned components into a crucible according to the proportions and mix them, and boil them at a temperature of 150-180°C for 15 minutes to remove the water and form a paste.

[0038] The brazing aid prepared in this embodiment is uniformly mixed, without delamination, and no visible inclusions, and the brazing aid has good spreadability on the solid silver solder sheet.

[0039] The method of welding two...

Embodiment 3

[0041] This embodiment provides a brazing aid for plane welding of tungsten steel, including the following components in parts by weight: KF: 50 parts, B 2 O 3 : 23 parts, CoCl 2 : 12 parts, composite fluoroborate: 8 parts, composite borate: 7 parts, surfactant: 4 parts, water: 68 parts. Among them, the composite fluoroborate is a mixture of potassium fluoroborate and ammonium fluoroborate at a mass ratio of 2:1, the composite borate is a mixture of sodium borate and potassium borate at a mass ratio of 1:1, and the surfactant is a perfluoroalkane 基amine. Put the above-mentioned components into a crucible according to the proportion and mix them, and boil them at a temperature of 150-180°C for 23 minutes to remove the water and form a paste.

[0042] The brazing aid prepared in this embodiment is uniformly mixed, without delamination, and no visible inclusions, and the brazing aid has good spreadability on the solid silver solder sheet.

[0043] The method of welding two tungsten st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com