Preparation method of Cu-doped BiVO4 porous nano-tube photocatalyst

A photocatalyst and nanotube technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of easy control, good repeatability and high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using polymer polyacrylonitrile (PAN) as the reaction reagent, using N,N-dimethylformamide (DMF) as the solvent, stirring at room temperature for 8 to 10 hours, sucking the above-mentioned mixed solution into a 5mL syringe, Electrospinning was carried out in a certain electric field (positive electric field was 15KV, negative electric field was -2KV), the distance between positive and negative electrodes was 15cm, and the advancing speed was 0.3mL·h -1 , and the obtained one-dimensional PAN nanofiber precursor was collected and dried in an oven at 80°C for 12h.

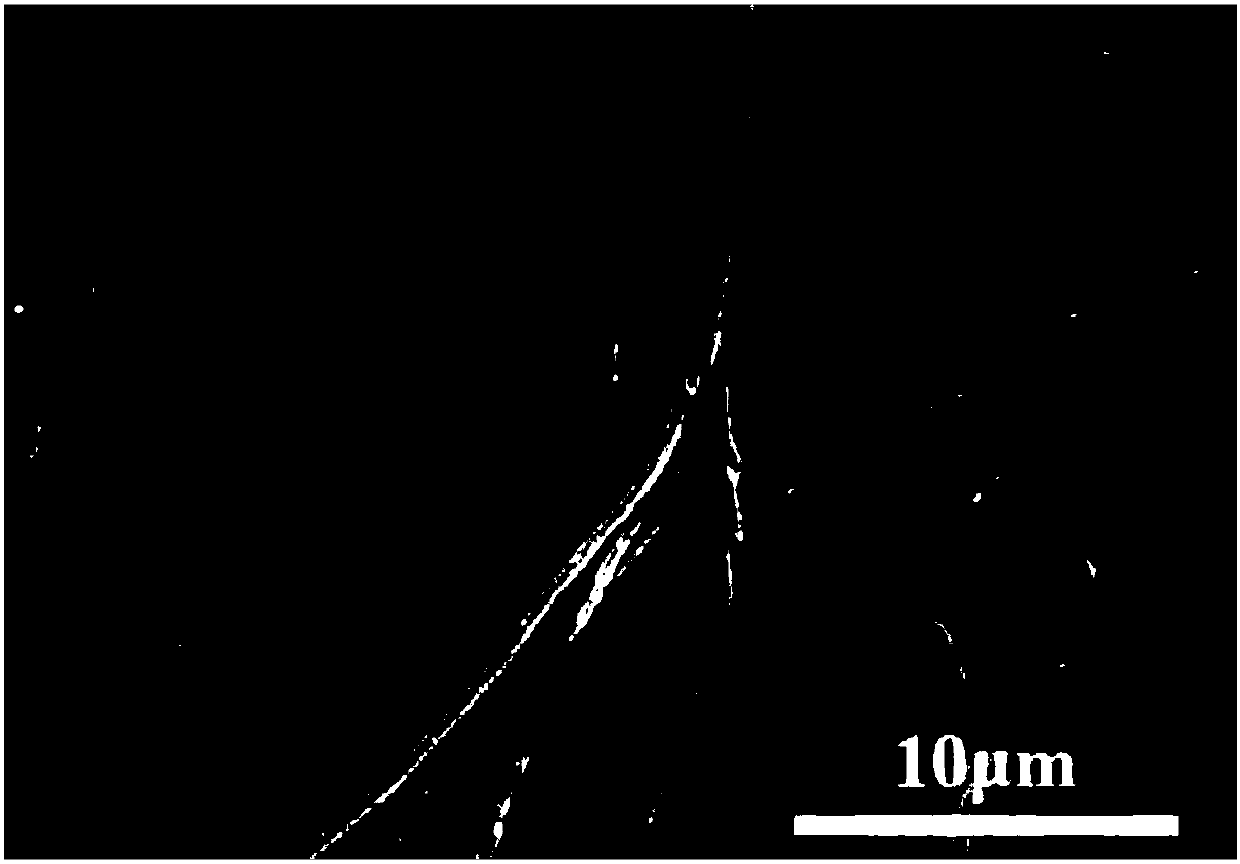

[0024] For a Cu-doped BiVO prepared in this example 4 Porous nanotube photocatalyst is analyzed by field emission scanning electron microscope, and the obtained electron microscope pictures are as follows: figure 2 , it can be seen that the spun silk has uniform shape and size, with a diameter of 400nm to 450nm.

Embodiment 2

[0026] Weigh 194mg (0.4mmol) bismuth nitrate (Bi(NO 3 )3 ) and 46.8mg (0.4mmol) ammonium metavanadate (NH 4 VO 3 ), add 10ml of ethylene glycol and 30ml of ethanol, form a homogeneous solution by ultrasonic dispersion, then fully stir for 30 minutes, then weigh the above obtained 15mg of PAN into the solution, put the mixed solution into the reaction kettle, and heat it at 160°C for 24 hours , after naturally cooling to room temperature, open the reactor, wash and centrifuge with deionized water and absolute ethanol, and dry the precipitate. Next, one-dimensional PAN@BiVO was obtained by calcining the above in air 4 For nanocomposite fiber products, heat up to 500°C with a heating rate of 2°C·min -1 , keep warm for 2 hours, get BiVO 4 Porous nanotube sample, labeled BiVO 4 . The products prepared in this example were analyzed by X-ray diffraction and field emission scanning electron microscopy.

[0027] For a Cu-doped BiVO prepared in this example 4 The porous nanotube...

Embodiment 3

[0029] Weigh 194mg (0.4mmol) bismuth nitrate (Bi(NO 3 ) 3 ), 3mg (0.012mmol) copper sulfate (CuSO 4 ) and 46.8mg (0.4mmol) ammonium metavanadate (NH 4 VO 3 ), add 10ml of ethylene glycol and 30ml of ethanol, form a homogeneous solution by ultrasonic dispersion, then fully stir for 30 minutes, then weigh the above obtained 15mg of PAN into the solution, put the mixed solution into the reaction kettle, and heat it at 160°C for 24 hours , after naturally cooling to room temperature, open the reactor, wash and centrifuge with deionized water and absolute ethanol, and dry the precipitate. Next, one-dimensional PAN@Cu-doped BiVO was obtained by calcination in air 4 Nanocomposite fibers, heating up to 500°C, the heating rate is 2°C·min -1 , keep warm for 2 hours, get BiVO 4 Porous nanotube sample, designation Cu-BiVO4-3.0%. The products prepared in this example were analyzed by X-ray diffraction and field emission scanning electron microscopy.

[0030] For a Cu-doped BiVO pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com