Wet fermentation protein feed for beef cattle and preparation method of wet fermentation protein feed

A beef cattle and protein technology, applied in the field of animal breeding, can solve the problems of inability to guarantee the quality, safety, hygiene and feeding effect of biological protein feed, unfavorable digestion and comprehensive nutrient absorption of beef cattle, and inability to make full use of straw resources, etc., so as to improve the utilization value. and breeding benefits, reducing the addition of dust and the loss of trace components, and improving the effect of feed utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

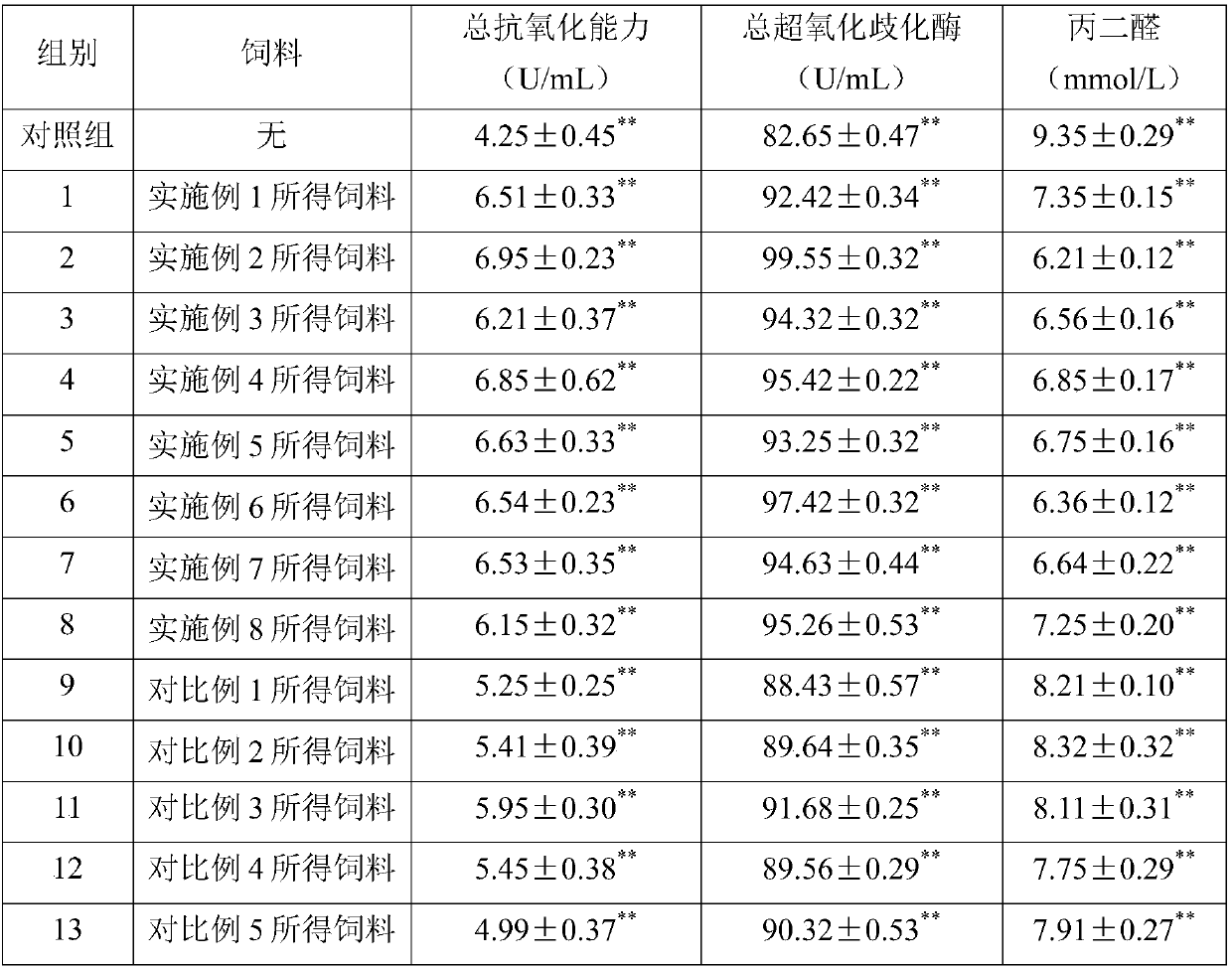

Examples

Embodiment 1

[0027] The embodiment of the present invention provides a method for preparing beef cattle feed of wet fermented protein, comprising the following steps:

[0028] (1) After mixing Saccharomyces cerevisiae and Kluyveromyces marx in a weight ratio of 1:1 to obtain a mixed yeast, the mixed yeast and deionized water are mixed in a weight ratio of 0.05:100 to obtain a yeast bacteria liquid.

[0029] In parts by weight, after mixing 20 parts of mixed yeast liquid, 60 parts of corn bran, 1 part of ammonium sulfate, 0.5 part of potassium dihydrogen phosphate, and 0.5 part of magnesium sulfate, use a mass concentration of 5% ammonia water Adjust the pH to 5.0, then place it in a sterile fermentation room, and carry out anaerobic fermentation at a temperature of 30°C and a relative humidity of 80% for 48 hours, then send the fermented material into a drying room, and dry it at a constant temperature of 40°C. Place in a pulverizer, pulverize to particles with a particle size of 2mm, and...

Embodiment 2

[0035] The embodiment of the present invention provides a method for preparing beef cattle feed of wet fermented protein, comprising the following steps:

[0036] (1) After mixing Saccharomyces cerevisiae and Kluyveromyces marx in a weight ratio of 1.5:1 to obtain a mixed yeast, the mixed yeast and deionized water are mixed in a weight ratio of 0.1:100 to obtain a yeast bacteria liquid.

[0037] In parts by weight, get 27 parts of mixed yeast liquid, 65 parts of corn bran, 2 parts of ammonium sulfate, 1 part of potassium dihydrogen phosphate, and 1 part of magnesium sulfate. After mixing evenly, adopt a mass concentration of 5% Adjust the pH to 5.5 with ammonia water, and then place it in a sterile fermentation room for anaerobic fermentation at a temperature of 31°C and a relative humidity of 80% for 60 hours. The fermented material is sent to a drying room and dried at a constant temperature of 40°C. Then place it in a pulverizer, pulverize to particles with a particle diam...

Embodiment 3

[0043] The embodiment of the present invention provides a method for preparing beef cattle feed of wet fermented protein, comprising the following steps:

[0044] (1) After mixing Saccharomyces cerevisiae and Kluyveromyces marx in a weight ratio of 2:1 to obtain a mixed yeast, the mixed yeast and deionized water are mixed in a weight ratio of 0.1:100 to obtain a yeast bacteria liquid.

[0045] In parts by weight, get 25 parts of mixed yeast liquid, 70 parts of corn bran, 3 parts of ammonium sulfate, 2 parts of potassium dihydrogen phosphate, and 1 part of magnesium sulfate. Adjust the pH to 6.0 with ammonia water, then place it in a sterile fermentation room, and perform anaerobic fermentation at a temperature of 33°C and a relative humidity of 85% for 60 hours, then send the fermented material to a drying room, and dry it at a constant temperature of 40°C. Then place it in a pulverizer, pulverize to particles with a particle diameter of 2 mm, and prepare a yeast culture for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com