Ship flue gas desulfurization and denitration device and technology

A flue gas and ship technology, applied in the field of atmospheric environmental protection, can solve the problems of lack of flue gas denitrification treatment systems for small ships, and achieve the effects of low construction cost, convenient construction or reconstruction, and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

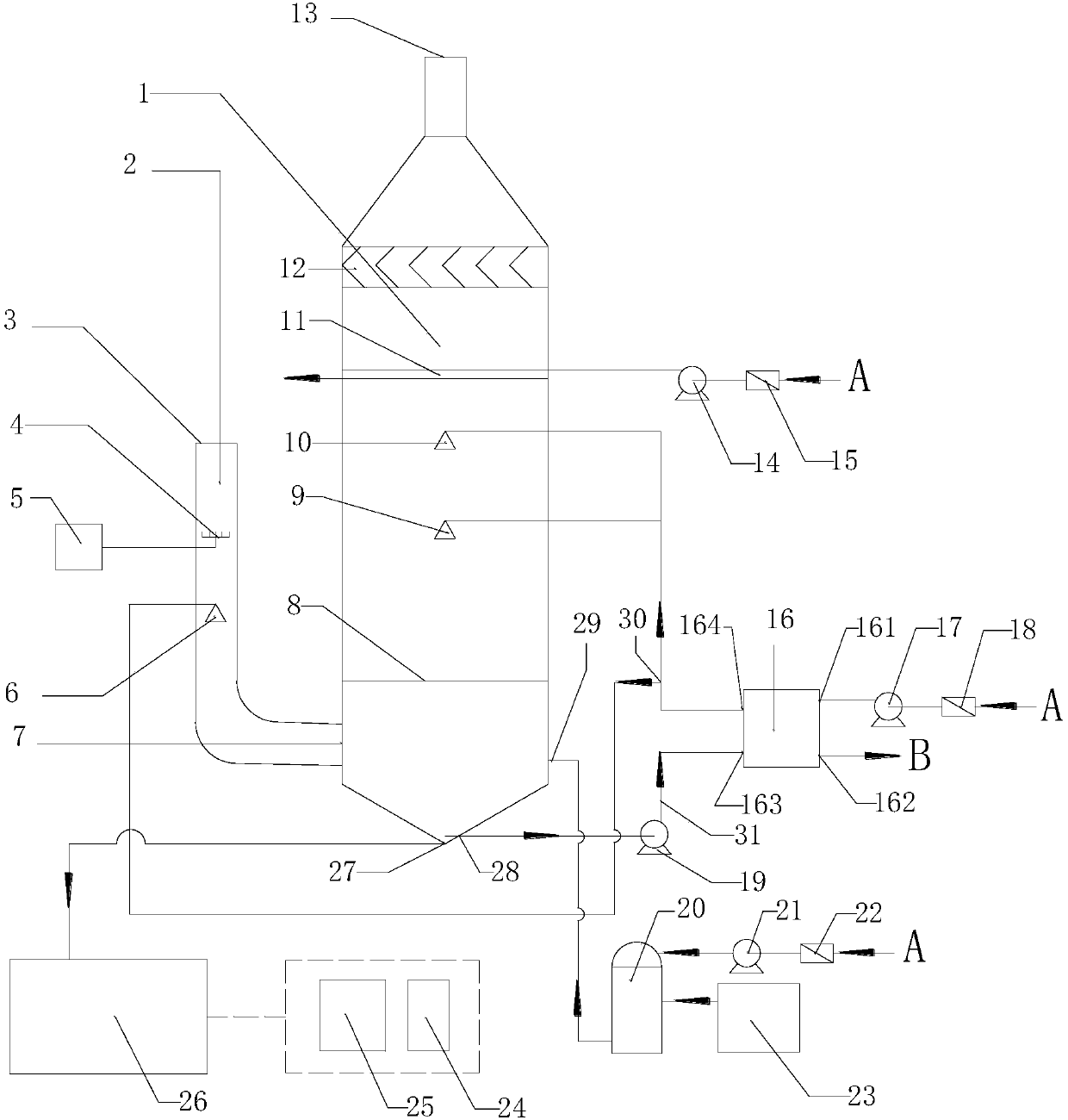

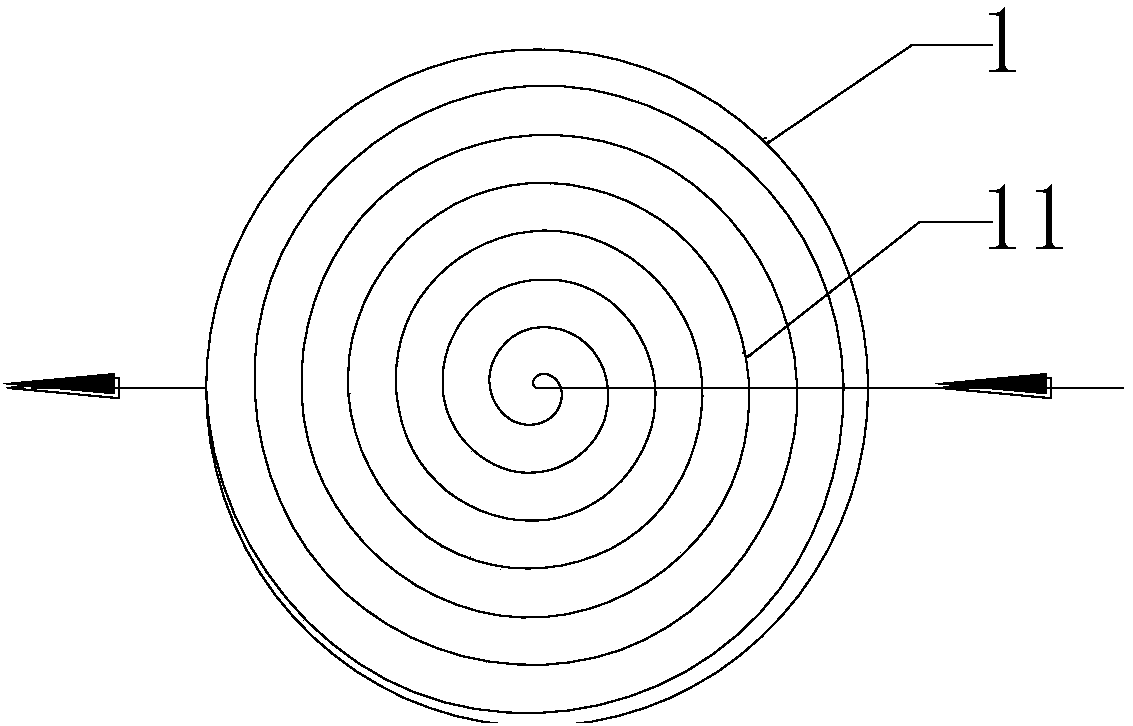

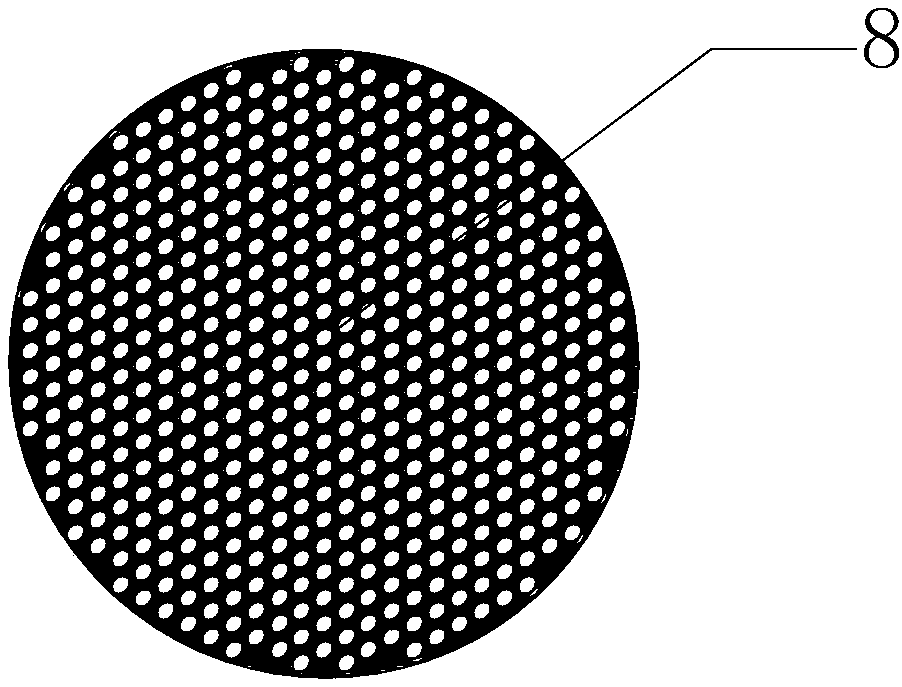

[0033] A ship flue gas desulfurization and denitrification device, such as figure 1 As shown, its main structure is the spray tower 1 and the flue 2 connected to it, the connection port between the spray tower 1 and the flue 2 is the air inlet 7 of the spray tower, and the passage before the air inlet 7 of the spray tower is A certain slope is inclined towards the tower body to prevent liquid from accumulating in the flue. A flue air inlet 3 is arranged at one end of the flue 2, and an ozone injector 4 and a first nozzle 6 are arranged in sequence along the movement direction of the flue gas, and the ozone injector 4 is connected to the ozone generator 5 through a pipe. The ozone generator 4 generates ozone, and the ozone is sprayed reversely to the flue gas in the flue 2 through the ozone injector 4. The ozone can oxidize low-valent nitrogen oxides and part of sulfur dioxide, which is convenient for subsequent spray absorption and removal. The ozone-treated flue gas enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com