Heating head capable of detecting hot-melting piece and heater

A technology of hot-melt sheet and heating head, applied in induction heating, induction heating device and other directions, can solve the problems of easy burnout of electromagnetic heating coil, damage to heating head, affecting normal welding work, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

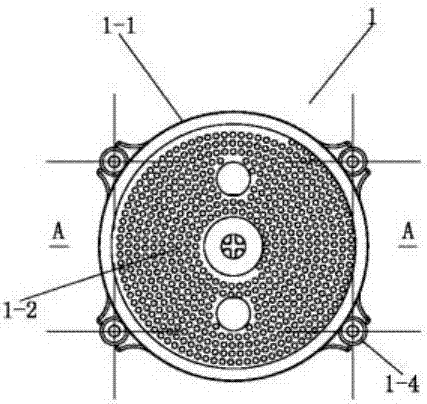

[0174] Such as Figure 1 to Figure 2 with Figure 40 As shown, this embodiment provides a thermal head 1 capable of detecting thermal melts, and the thermal head 1 capable of detecting thermal melts is equipped with a thermal melt detector 1-4.

[0175] Various improvements as this embodiment are described below.

[0176] The hot melt detectors 1-4 are metal detectors.

[0177] The metal detector is an electromagnetic induction type metal detector, an X-ray detection type metal detector, or an ultrasonic detection type metal detector.

[0178] The metal detector is a magnetoelectric sensor.

[0179] The magnetoelectric sensor is a proximity switch.

[0180] The shape of the hot melt detector 1-4 is columnar.

[0181] There is at least one thermal melt detector 1-4.

[0182] There are four thermal melt detectors 1-4.

[0183] The four thermal fuse detectors 1-4 are distributed on the side of the heating head 1 at the shield outside the magnetic core wall.

[0184] The dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com