Method for recovering aluminum foil and positive active material from waste lithium ion battery

A positive electrode active material and lithium ion battery technology, applied in the chemical industry, can solve the problem of high loss rate of positive electrode active material, and achieve the effects of high screening efficiency, high separation efficiency and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

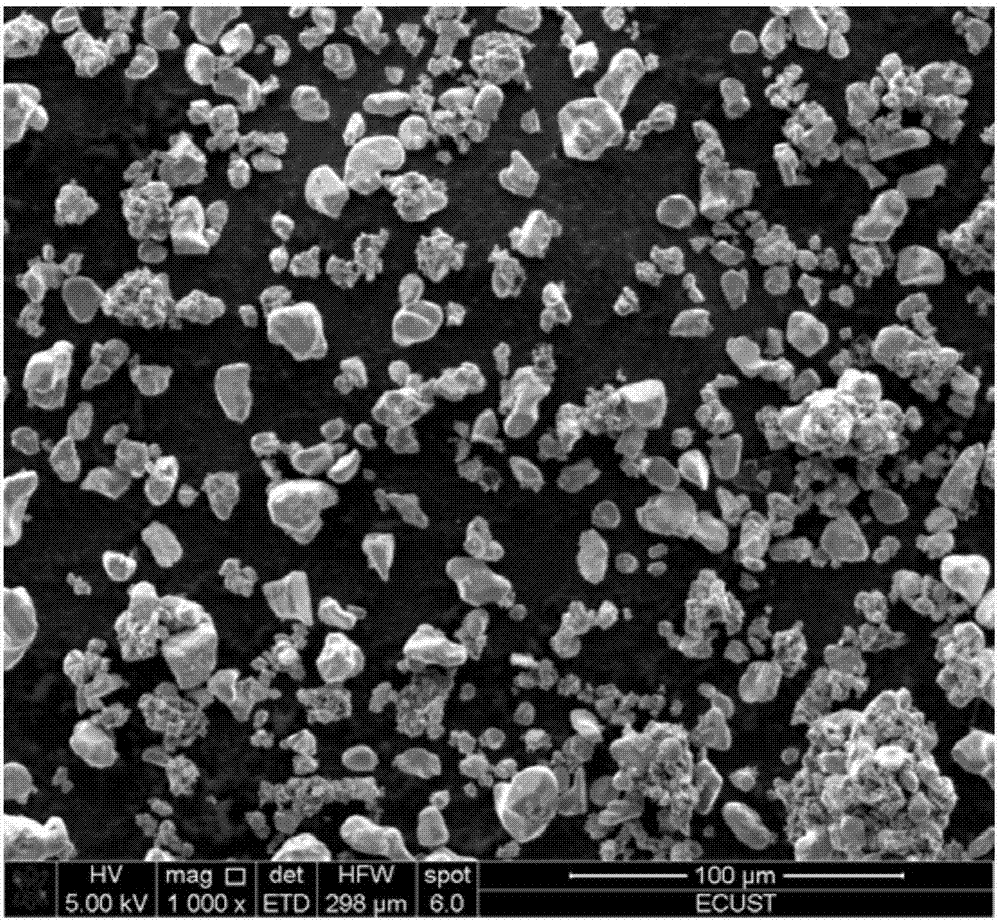

[0047] like figure 1 As shown, the recovery route is as follows:

[0048] Fully discharge the waste lithium cobalt oxide battery, physically disassemble and remove the shell in the glove box, and take out the positive electrode piece; cut the positive electrode piece into a size of 2cm×2cm, put it into the conical flask; add N,N -After dimethylacetamide, put it into an ultrasonic cleaning machine, control the temperature at 60°C, and ultrasonic frequency at 20KHz, and wash for 30 minutes; filter, and recycle the separated organic solvent. The material is the current collector aluminum foil, and the undersize is the positive electrode active material and the conductive agent. In this example, the removal rate of the positive electrode active material was 71.71%.

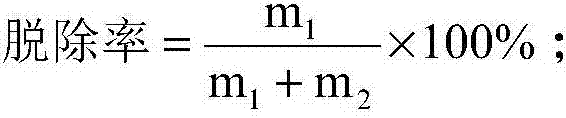

[0049] The calculation formula of removal rate is as follows (hereinafter the same):

[0050]

[0051] In the formula, m 1 is the mass of the separated positive electrode material (positive electrode active mater...

Embodiment 2

[0053] Fully discharge the waste lithium cobalt oxide battery, physically disassemble and remove the shell in the glove box, and take out the positive electrode piece; cut the positive electrode piece into a size of 2cm×2cm, put it into the conical flask; add N,N -After dimethylformamide, put it into an ultrasonic cleaning machine, control the temperature at 60°C, and ultrasonic frequency at 40KHz, and wash for 30 minutes; filter, the separated solvent is recycled, and the solid matter is dried and passed through a 50 μm sieve. It is the current collector aluminum foil, and the undersize is the positive electrode active material and the conductive agent. In this example, the removal rate of positive electrode active material is 62.11%.

Embodiment 3

[0055] Fully discharge the waste lithium cobalt oxide battery, physically disassemble and remove the shell in the glove box, and take out the positive electrode piece; cut the positive electrode piece into a size of 2cm×2cm, put it into the conical flask; add dimethyl to the conical flask After sulfoxide, put it into an ultrasonic cleaning machine, control the temperature at 40°C, and ultrasonic frequency at 20KHz, and wash for 30 minutes; filter, the separated solvent is recycled, and the solid matter is dried and passed through a 50 μm sieve, and the sieve is the current collector aluminum foil , the undersieve is positive electrode active material and conductive agent. In this example, the removal rate of positive electrode active material is 45.31%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com