Method of improving luster and anti-wrinkle property of cotton fabric by steaming dyeing method

A dyeing method and cotton fabric technology, applied in the field of textile printing and dyeing, can solve the problems of high energy consumption and long production process, and achieve the effects of reduced water consumption, improved quality, and high color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

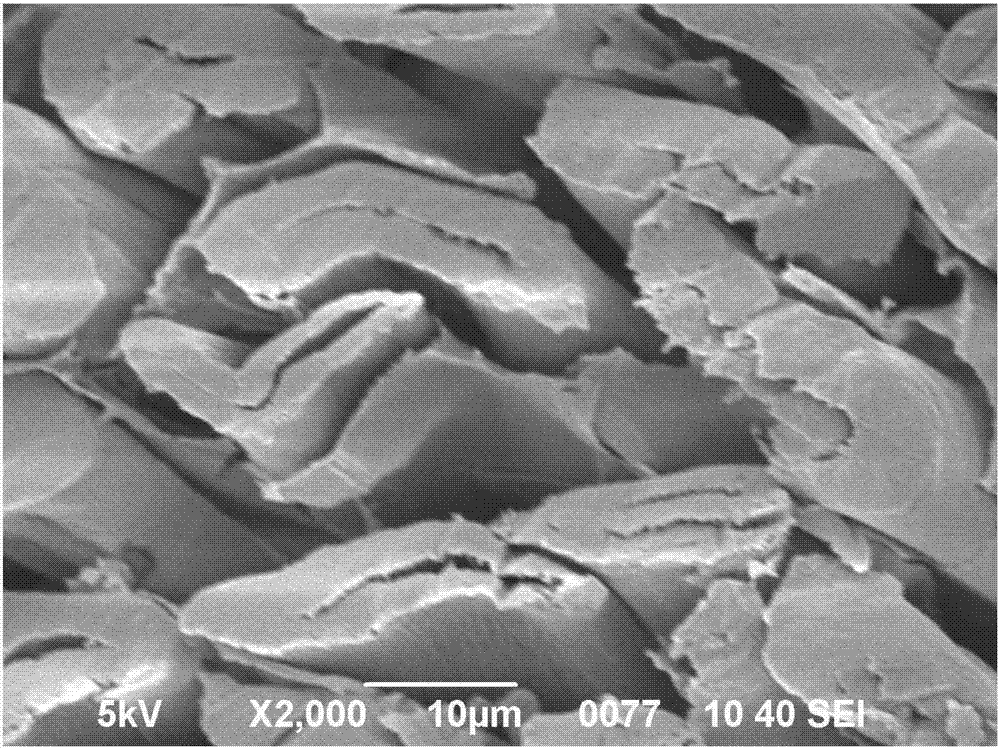

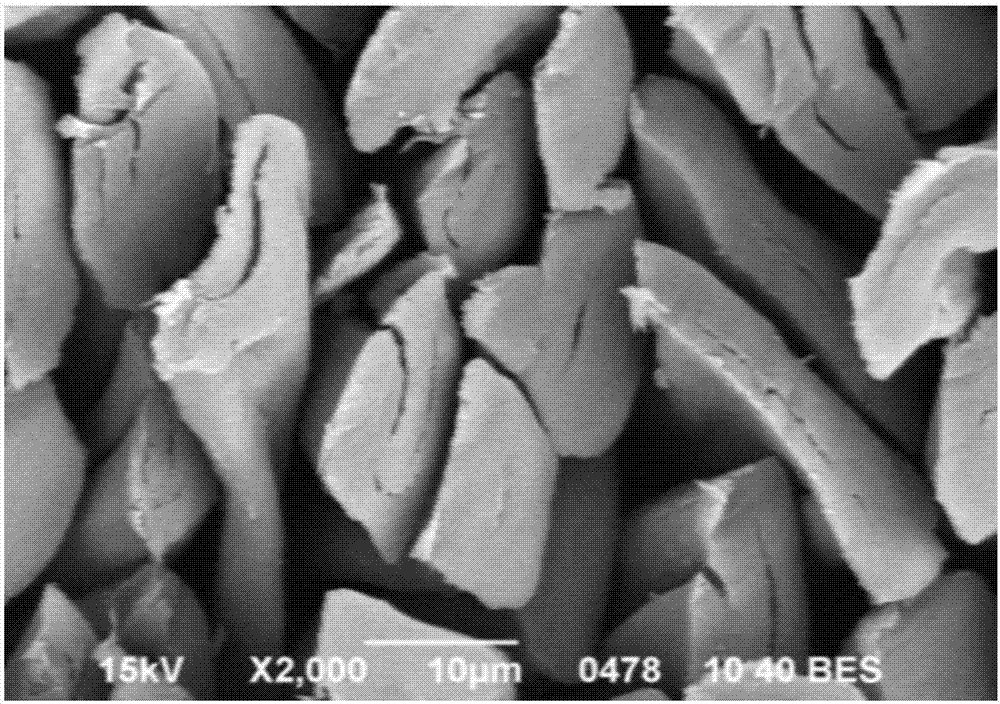

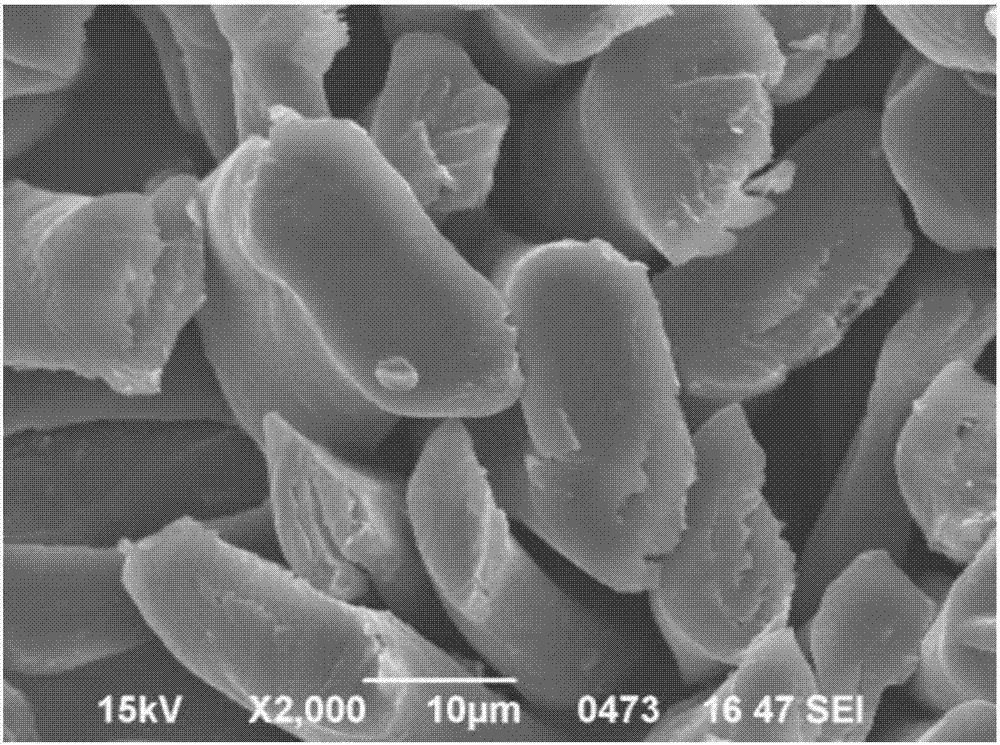

Image

Examples

Embodiment 1

[0036] A method for improving the luster and wrinkle resistance of cotton fabrics by steam dyeing, comprising the following main steps:

[0037] Step 1: according to fatty acid methyl ester ethoxylate compound, 10g / L, reactive blue 19 are 5g / L preparation dye aqueous solution, and sodium silicate is 30g / L, secondary alkyl sodium sulfonate is 70g / L preparation alkaline agent aqueous solution;

[0038] Step 2: According to the ratio of the volume ratio of dye solution: alkaline agent solution is 4:1, fully mix and add to the dyeing tank, the fabric passes through the dyeing tank and is pad-rolled with a uniform padding machine, and the excess rate is 50-100%;

[0039] Step 3: within 30-600s, the fabric after padding enters a steam box with a temperature of 100±1°C and contains saturated steam for 30-180s;

[0040] Step 4: Wash and soap with water and dry to complete the dyeing process.

Embodiment 2

[0042] A method for improving the luster and wrinkle resistance of cotton fabrics by steam dyeing, comprising the following main steps:

[0043] Step 1: prepare the aqueous dye solution according to 7g / L of fatty alcohol ether sodium sulfate, g / L of reactive black 5, 15g / L of sodium metasilicate, 1g / L of sodium hydroxide, and 1,3,5-tripropylene Amide hexahydro-s-triazine is 60g / L to prepare alkaline agent aqueous solution;

[0044] Step 2: According to the ratio of the volume ratio of dye solution: alkaline agent solution is 4:1, fully mix and add to the dyeing tank, the fabric passes through the dyeing tank and is pad-rolled with a uniform padding machine, and the excess rate is 50-100%;

[0045] Step 3: within 30-600s, the fabric after padding enters a steam box with a temperature of 100±1°C and contains saturated steam for 30-180s;

[0046] Step 4: Wash and soap with water and dry to complete the dyeing process.

Embodiment 3

[0048] A method for improving the luster and wrinkle resistance of cotton fabrics by steam dyeing, comprising the following main steps:

[0049] Step 1: According to sodium lauryl sulfate 5g / L, active yellow 1 is 15g / L preparation dye aqueous solution, trisodium phosphate is 10g / L, sodium bicarbonate is 10g / L, 2,4-disubstituted dichloro 30 g / L of s-triazinebenzenesulfonic acid is used to prepare aqueous alkali solution;

[0050] Step 2: According to the ratio of the volume ratio of dye solution: alkaline agent solution is 4:1, fully mix and add to the dyeing tank, the fabric passes through the dyeing tank and is pad-rolled with a uniform padding machine, and the excess rate is 50-100%;

[0051] Step 3: within 30-600s, the fabric after padding enters a steam box with a temperature of 100±1°C and contains saturated steam for 30-180s;

[0052] Step 4: Then wash and soap with water and dry to complete the dyeing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com