A kind of high-temperature-resistant silicone gel for high-power igbt encapsulation and its preparation method and application

A high-power, high-temperature-resistant technology, applied in the field of silicone gel, can solve the problem of difficult to meet the use temperature, and achieve the effect of improving heat resistance, tight cross-linking, good light transmittance and cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

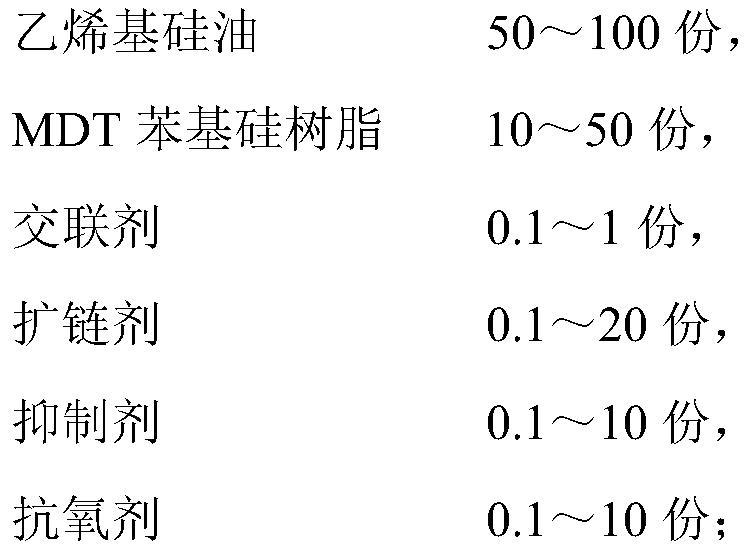

[0038] A high-temperature-resistant silicone gel for high-power IGBT packaging of the present invention includes component A and component B, wherein component A is formed by mixing the following raw materials by mass fraction:

[0039] Vinyl silicone oil 10kg;

[0040] Platinum catalyst 0.3kg;

[0041] Component B is made by mixing the following raw materials by mass:

[0042]

[0043] Among them, the vinyl silicone oil is methyl phenyl-terminated vinyl silicone oil with a vinyl content of 0.30%, the mass ratio of the phenyl content is 20%, the viscosity is 1000 mPa·s, and the purity is > 99.98%; Hydrogen silicone oil, its hydrogen content is 0.50%, the mass ratio of phenyl content is 15%, the purity is more than 99.98%, and the viscosity is 15mPa s; the chain extender is 0.10% hydrogen content and 10% phenyl content mass ratio- 50% (15%), purity>99.98%, methylphenyl hydrogen-containing silicone oil with viscosity of 10mPa·s; wherein the platinum catalyst is Shin-Etsu pl...

Embodiment 2

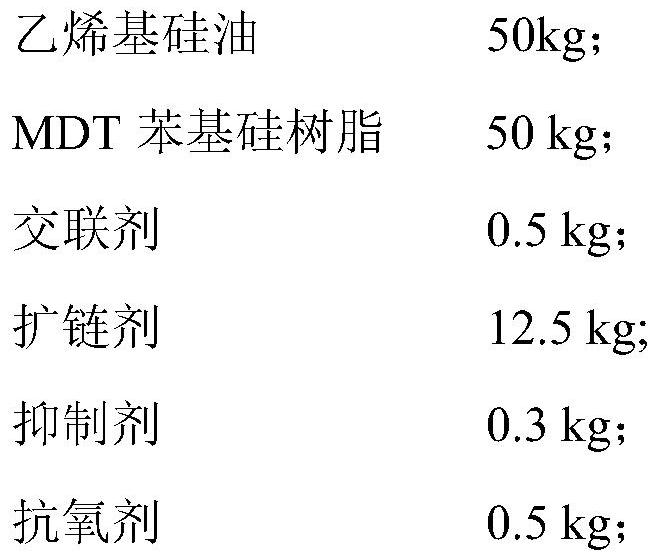

[0057] A high-temperature-resistant silicone gel for high-power IGBT packaging of the present invention includes component A and component B, wherein component A is formed by mixing the following raw materials by mass fraction:

[0058] Vinyl silicone oil 10kg;

[0059] Platinum catalyst 0.3kg;

[0060] Component B is made by mixing the following raw materials by mass:

[0061]

[0062] Among them, the vinyl silicone oil is methylphenyl-terminated vinyl silicone oil with a vinyl content of 0.23%, the mass ratio of the phenyl content is 10%, the viscosity is 1000mPa·s, and the purity is >99.98%; the crosslinking agent is the hydrogen content of 0.65% , methyl phenyl hydrogen-containing silicone oil with phenyl content mass ratio of 28%, purity > 99.98%, and viscosity of 30mPa s; chain extender is hydrogen content of 0.12%, phenyl content mass ratio of 25%, purity > 99.98% methylphenyl hydrogen-containing silicone oil with a viscosity of 20mPa·s; platinum catalyst is Shin-E...

Embodiment 3

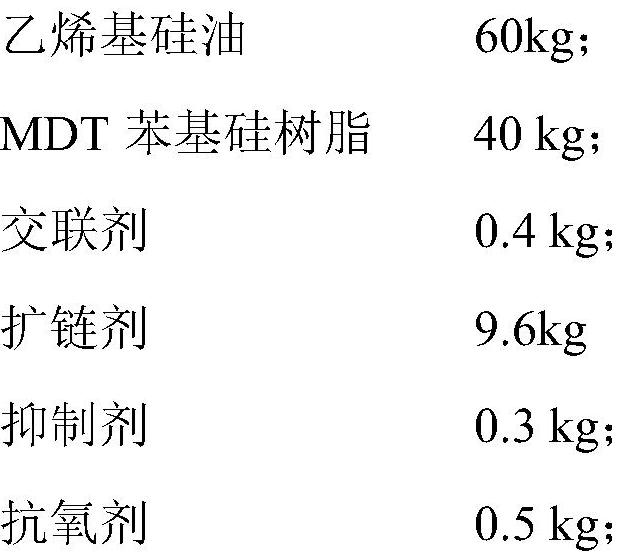

[0076] A high-temperature-resistant silicone gel for high-power IGBT packaging of the present invention includes component A and component B, wherein component A is formed by mixing the following raw materials by mass fraction:

[0077] Vinyl silicone oil 10kg;

[0078] Platinum catalyst 0.3kg;

[0079] Component B is made by mixing the following raw materials by mass:

[0080]

[0081] Among them, the vinyl silicone oil is methylphenyl-terminated vinyl silicone oil with a vinyl content of 0.32%, the mass ratio of the phenyl content is 20%, the viscosity is 1000mPa·s, and the purity is >99.98%; the crosslinking agent is a hydrogen content of 0.52% %, the phenyl content mass ratio is 25%, the purity is >99.98%, the viscosity is 20mPa·s methyl phenyl hydrogen-containing silicone oil, the chain extender is the hydrogen content 0.18%, the phenyl content mass ratio is 15%%, Methylphenyl hydrogen-containing silicone oil with purity >99.98% and viscosity of 15mPa·s; platinum cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com