Method for preparing polycarbonate based on high-efficiency catalysis by ionic liquid

A technology of ionic liquid and polycarbonate, which is applied in the field of polycarbonate prepared by melt transesterification reaction, can solve the problems of low activity, low molecular weight of polycarbonate, metal residue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

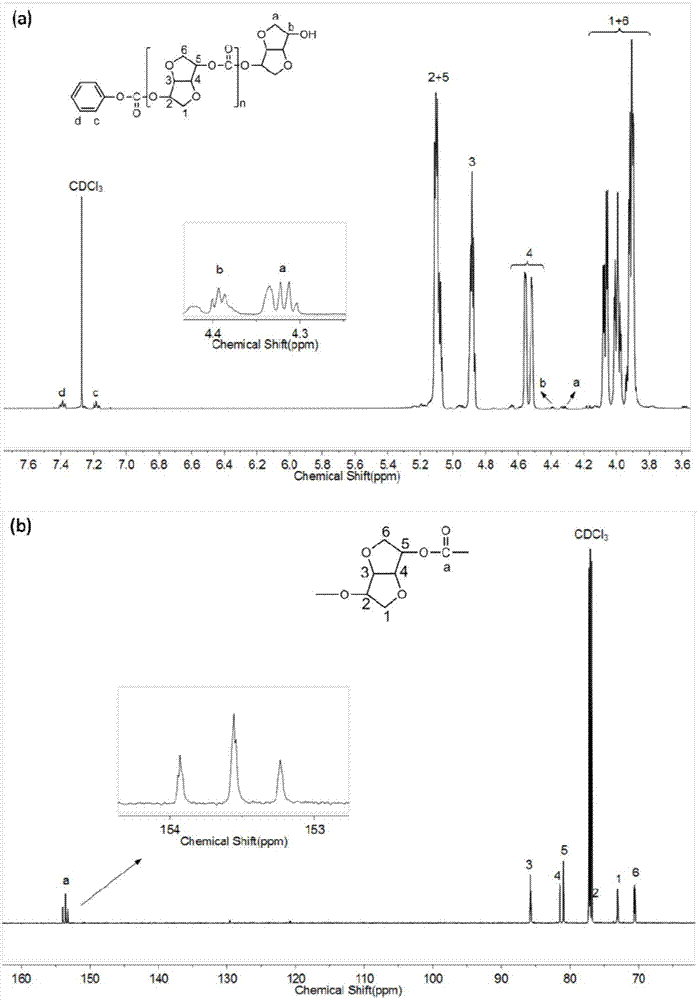

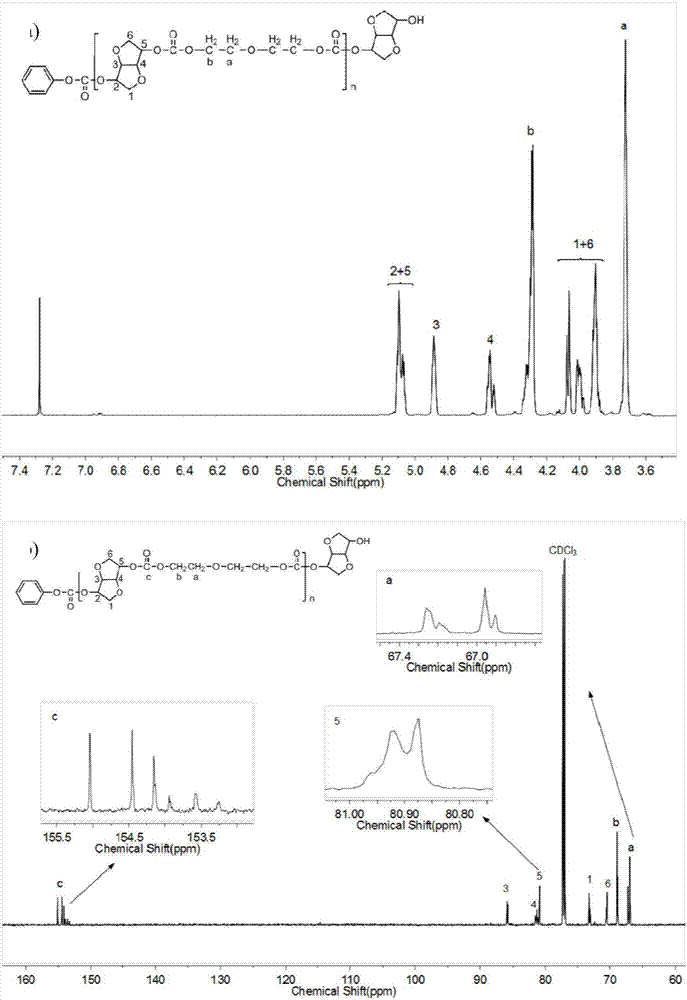

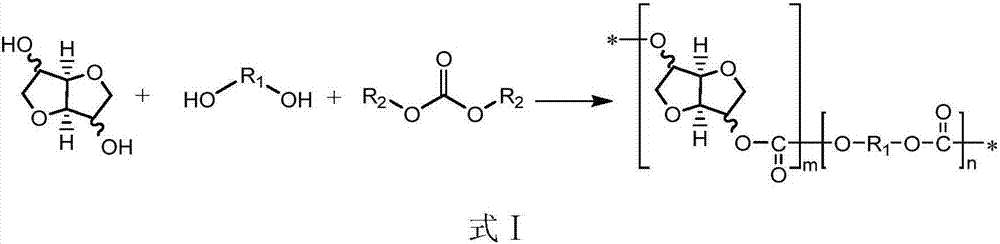

Method used

Image

Examples

Embodiment 1

[0028]

[0029] Under a nitrogen atmosphere, add 4.38g (0.03mol) isosorbide, 6.42g (0.03mol) diphenyl carbonate to a 250ml glass flask, melt at 100°C, add 3.42×10 -3 g (5×10 of the amount of isosorbide substance -2 %) 1-butyl-3-methylimidazole lactate ([Bmim][CH 3 CHOHCOO]), its structural formula is The transesterification reaction was carried out under normal pressure for 5h to synthesize the prepolymer. Then the reaction temperature was slowly raised to 240° C., the vacuum degree was slowly raised to 0.1 MPa, and the polycondensation reaction was carried out for 0.5 h to finally obtain the polycarbonate shown in formula I. The yield was 99%, the number average molecular weight was 61700 g / mol, and the glass transition temperature was 174°C.

Embodiment 2

[0031] With embodiment 1, catalyst used is 6.28 * 10 -3 g (5×10 of the amount of isosorbide substance -2 %) 1-butyl-3-methylimidazolium bis(trifluoromethanesulfonyl)imide salt ([Bmim][NTf 2 ]), whose structural formula is The polycondensation reaction time is 3h, and other conditions remain unchanged. The yield was 96%, the number average molecular weight was 12000 g / mol, and the glass transition temperature was 152°C.

Embodiment 3

[0033] With embodiment 1, catalyst used is 2.34 * 10 -3 g (5×10 of the amount of isosorbide substance -2 %) Hydroxide 1-butyl-3-methylimidazole ([Bmim][OH]), its structural formula is Other conditions remain unchanged. The yield was 98%, the number average molecular weight was 46000 g / mol, and the glass transition temperature was 172°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com