A kind of method utilizing solid super base to prepare fatty amide dimethyl tertiary amine compound

A technology of solid super strong base and dimethyl tertiary amine, which is applied in the preparation of organic compounds, chemical instruments and methods, and the preparation of carboxylic acid amides. It can solve the problems of complex operation, difficult recovery, environmental hazards, etc. The effect of less amount, simple reaction process and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

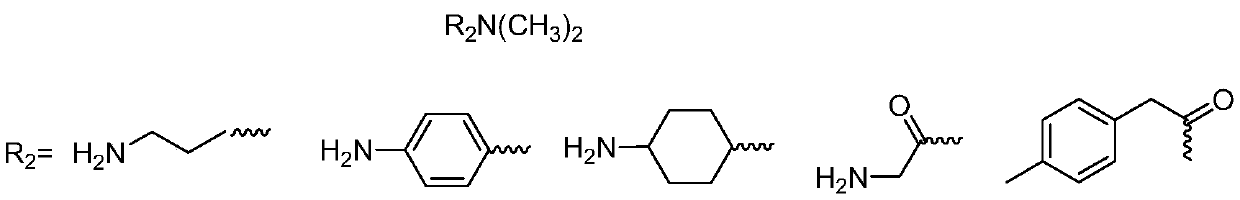

Method used

Image

Examples

Embodiment 1

[0016] In terms of molar ratio, stearic acid: N,N-dimethylpropylamine: KF / Al 2 o 3 =1.2:1:0.01 Prepare the raw materials. Add stearic acid, N,N‐dimethylpropylamine, KF / Al 2 o 3 , stirring and heating up to 60°C, keeping the temperature for reaction for 1 hour; stirring and heating up to 110°C, keeping the temperature for reaction for 8 hours; cooling to room temperature, the obtained reddish-brown viscous solid is stearamidopropyl dimethyl tertiary amine of the present invention , yield 98%.

[0017] IR (neat) ν: 3394, 2925, 2855, 1647, 1554, 1463, 1376, 1265, 723cm ‐1 ; 1 H NMR (400MHz, CDCl 3 ): δ=0.87(t,3H),1.21(t,28H),1.55‐1.67(m,4H),2.13(t,2H),2.22(s,6H),2.35(t,2H),3.30‐ 3.34(m,2H)..

Embodiment 2

[0019] In molar ratio, oleic acid: N,N‐dimethylpropylamine: K / γ‐Al 2 o 3 =1:1:0.01 Prepare the raw materials. Add oleic acid, N,N‐dimethylpropylamine, K / γ‐Al 2 o 3 , stirred and heated up to 60°C, kept the temperature for 1 hour; stirred and heated up to 110°C, kept the temperature for 8 hours; cooled to room temperature, the obtained reddish-brown viscous solid is the oleic acid amidopropyl dimethyl tertiary Amine, yield 99%

[0020] IR (neat) ν: 3392, 3081, 2925, 2855, 1645, 1552, 1461, 1375, 1263, 722cm ‐1 ; 1 H NMR (400MHz, CDCl 3 ): δ=0.88(t,3H),1.25‐1.30(m,20H),1.60‐1.67(m,4H),1.99‐2.05(m,4H),2.12(t,2H),2.22(s,6H ), 2.35(t,2H), 3.30‐3.35(m,2H), 5.34(t,2H).

Embodiment 3

[0022] In terms of molar ratio, stearic acid: oleic acid: N,N‐dimethylpropylamine: KNO 3 / ZrO 2 =1:1:2:0.02 Prepare the raw materials and add stearic acid, oleic acid, N,N‐ Dimethylpropylamine, KNO 3 / ZrO 2 , stirring and heating up to 40°C, keeping the temperature for 2 hours; stirring and heating up to 120°C, keeping the temperature for 9 hours; cooling to room temperature, the obtained reddish-brown viscous solid is stearamidopropyldimethyl tertiary stearamidopropyldimethyl of the present invention Amine and oleic acid amidopropyl dimethyl tertiary amine mixture, yield 98%.

[0023] IR (neat) ν: 3310, 3083, 2924, 2853, 1563, 1648, 1464, 1400, 1308, 1043, 721cm ‐1 ; 1 HNMR (400MHz, CDCl 3 ): δ=0.88(t,6H),1.21(t,28H),1.25‐1.30(m,20H),1.55‐1.67(m,8H),1.99‐2.05(m,4H),2.13(t,4H ), 2.22(s,12H), 2.35(t,4H), 3.30‐3.34(m,4H), 5.35(t,2H).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com