A printing and forming device and method for a colorful hollow glass structure

A kind of colorful and glass technology, applied in glass molding, decorative structure, glass manufacturing equipment, etc., can solve the problems of limited complex shape, long production cycle, high cost, etc., achieve low cost, reduce processing cost, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

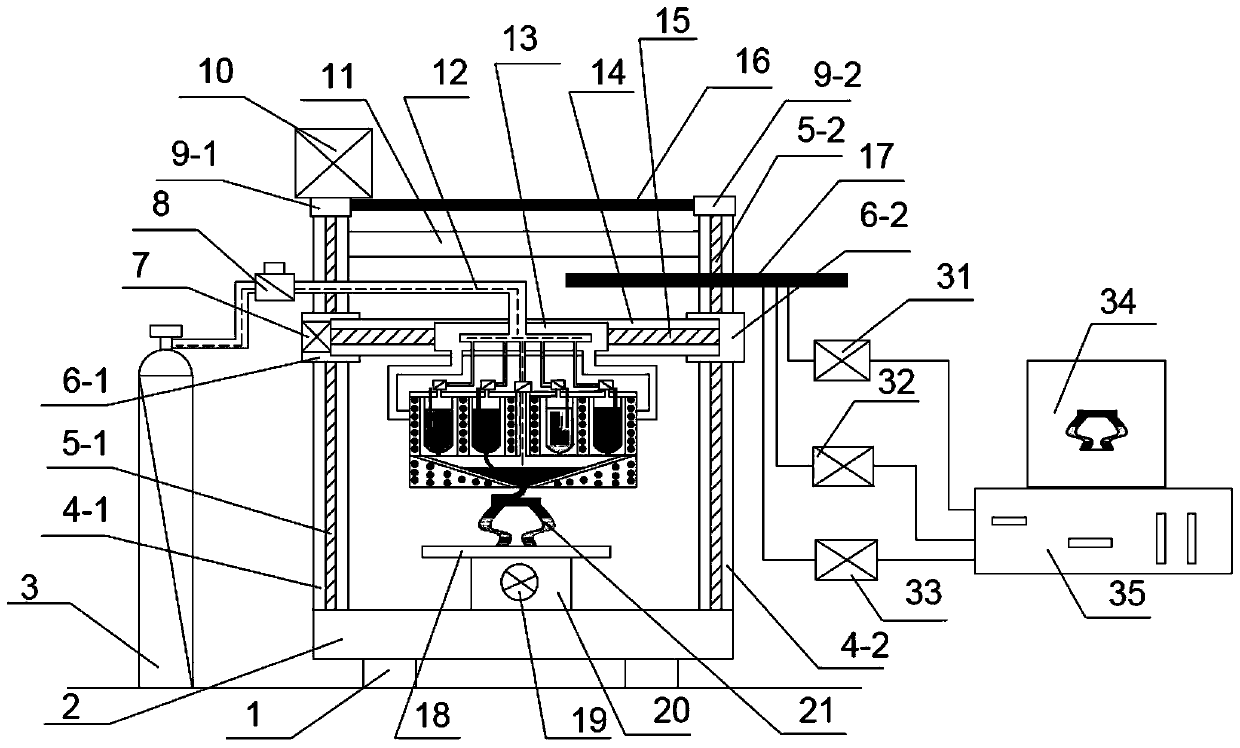

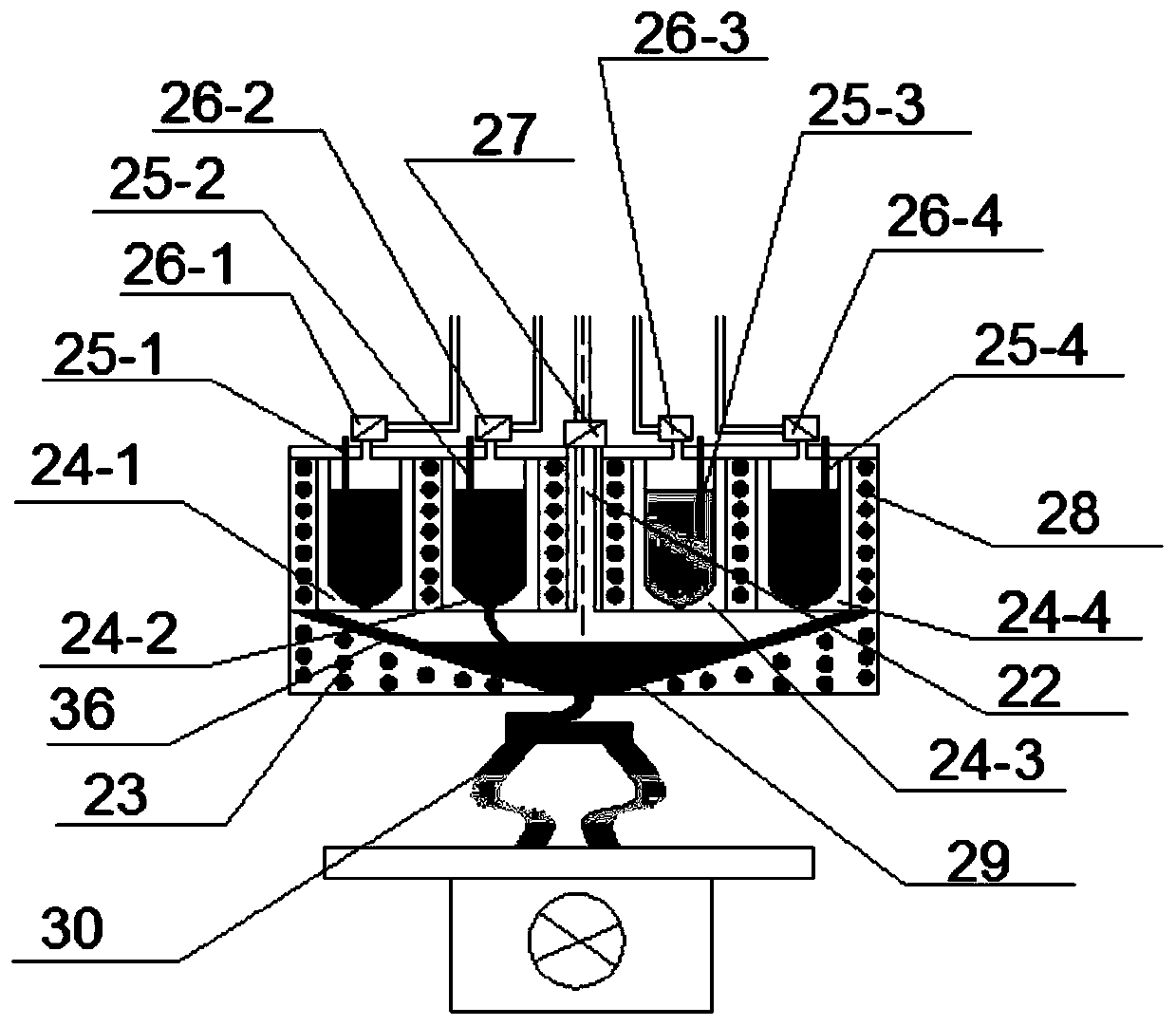

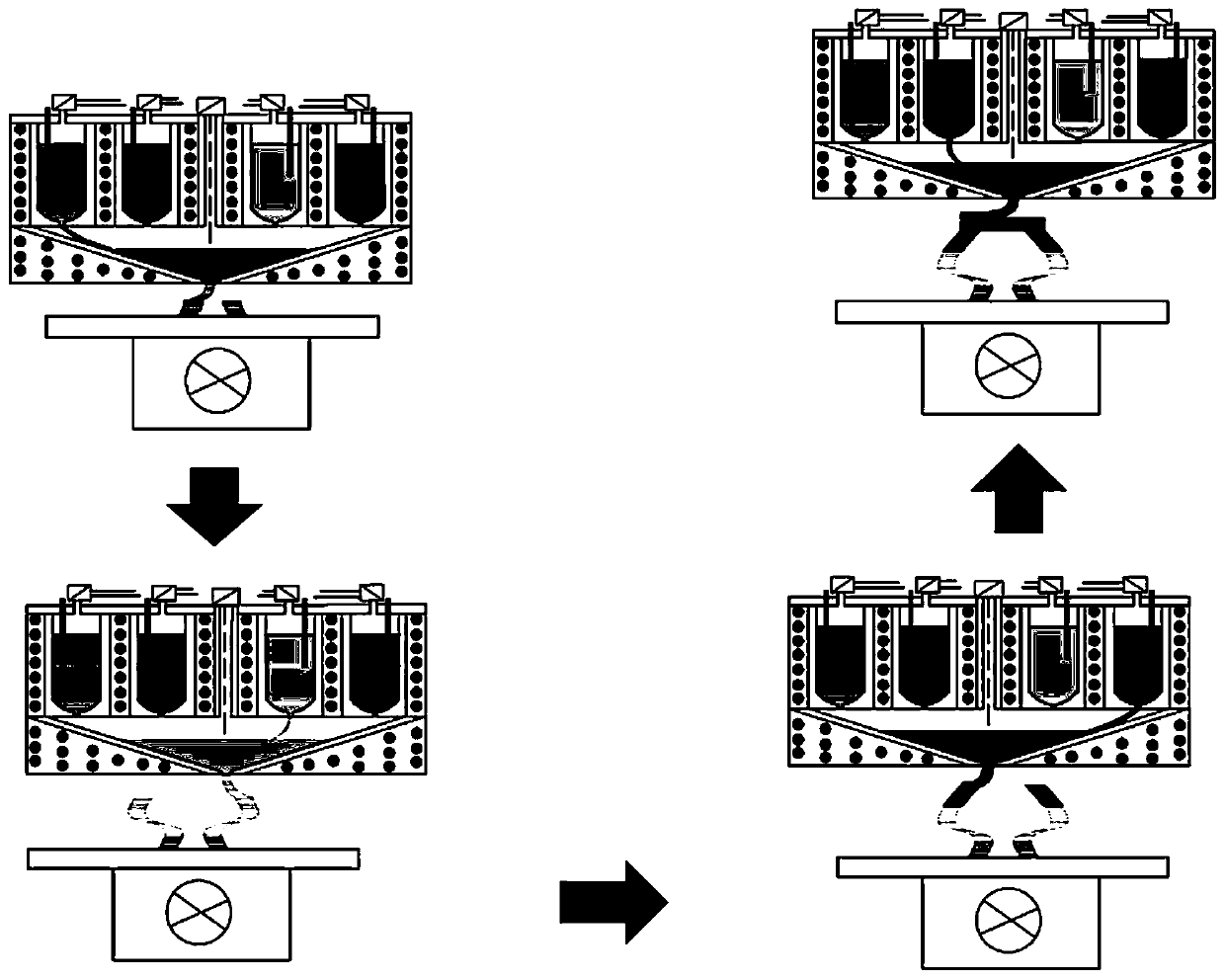

[0064] Example 1: Four-color hollow glass structure printing

[0065] According to the size and color requirements of the printed colorful hollowed-out glass structure 21, select yellow, red, blue and white four-color glass balls as printing materials, select glass melting crucible 1 24-1, glass melting crucible 2 24-2, glass melting crucible The diameter of the nozzle at the bottom of No. 3 24-3 and glass melting crucible No. 4 24-4 is 1.5 mm, and the diameter of the nozzle at the bottom of extrusion chamber crucible 36 is 1 mm, and put the four-color glass raw materials into glass melting crucible No. 1 24-1 respectively. , glass melting crucible two 24-2, glass melting crucible three 24-3 and glass melting crucible four 24-4; start computer control system 35 and multi-axis motion controller 32, open touch screen man-machine interface 34, to X Axis servo motor 7, Y-axis servo motor 19 and Z-axis servo motor 10 perform servo power-on debugging to ensure that X-axis linear sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com