Novel DLP-3D printer

A DLP-3D and printer technology, applied in the field of 3D printing, can solve the problems of inconvenient transportation, installation and processing, limited size, etc., and achieve the effect of convenient transportation and installation, convenient processing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

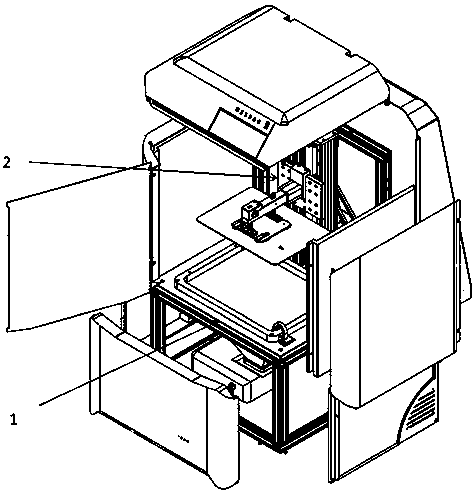

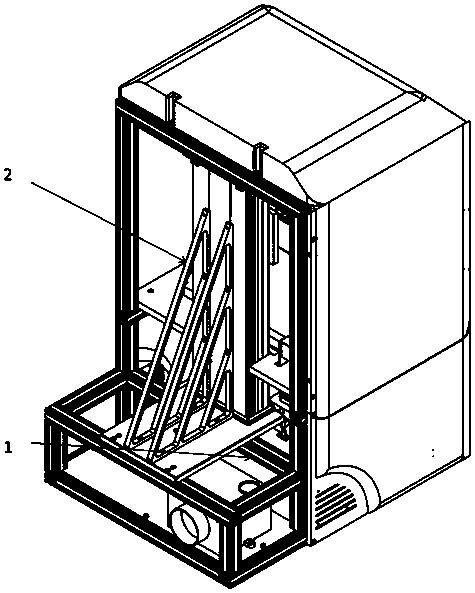

[0050] This embodiment provides a new type of DLP-3D printer, such as Figure 1~2 , including liquid surface forming system 1 and Z-axis motion system 2.

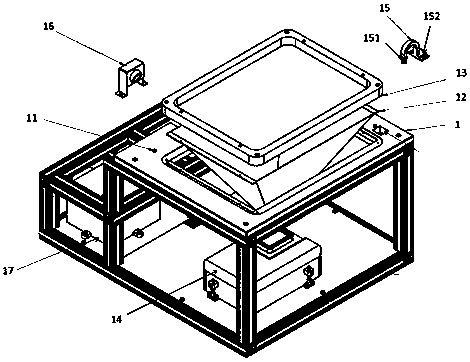

[0051] Such as image 3 The liquid surface forming system 1 includes an intermediate plate 11, a light source cover 12 disposed on the intermediate plate 11, a liquid tank 13 disposed on the light source cover 12, a light source 14, and a liquid outlet device 15 for delivering printing materials to the liquid tank 13 , an infrared camera 16 for monitoring the liquid level state of the liquid tank 13 and a temperature controller 17 for monitoring the temperature of the liquid tank 13 .

[0052]Specifically, the light source 14 is a DLP projector, and an adjustment seat is provided at the bottom thereof to adjust the horizontal accuracy of the light source. The liquid outlet device 15 includes a liquid outlet 151 and a liquid level detection device 152. The liquid level detection device 152 is a laser detection device for d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com