Aspherical glass lens multi-station precision molding equipment

A glass lens and precision molding technology, applied in glass molding, glass manufacturing equipment, glass production, etc., can solve problems such as low efficiency, long molding time, and unsuitability for industrial scale mass production, so as to ensure product molding accuracy and improve Production efficiency and the effect of improving the overall performance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

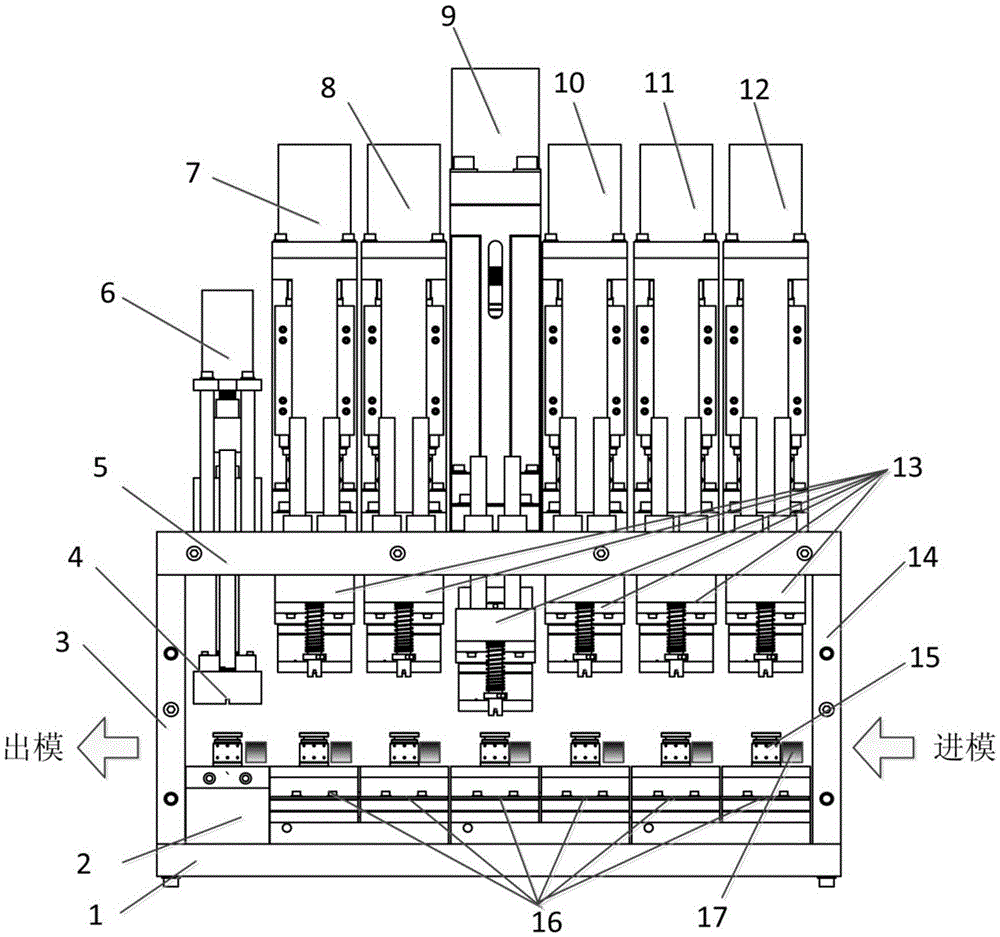

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

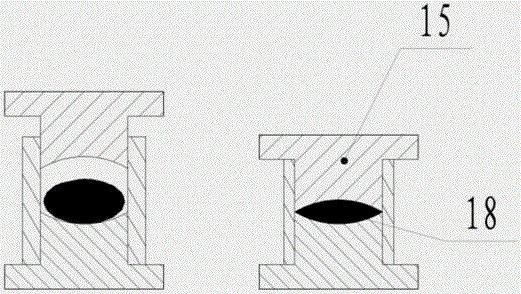

[0019] The present invention can realize high-precision thermocompression molding of aspheric glass lenses with different diameters, such as image 3 As shown, taking the processing of an aspheric glass lens with a caliber of 10 mm as an example, the positioning surface of the mold 15 has been finely ground, the molding surface has been ground and polished to nano-level roughness, and the inner surface of the mold is coated. The high-precision mold can guarantee High quality aspheric glass lens.

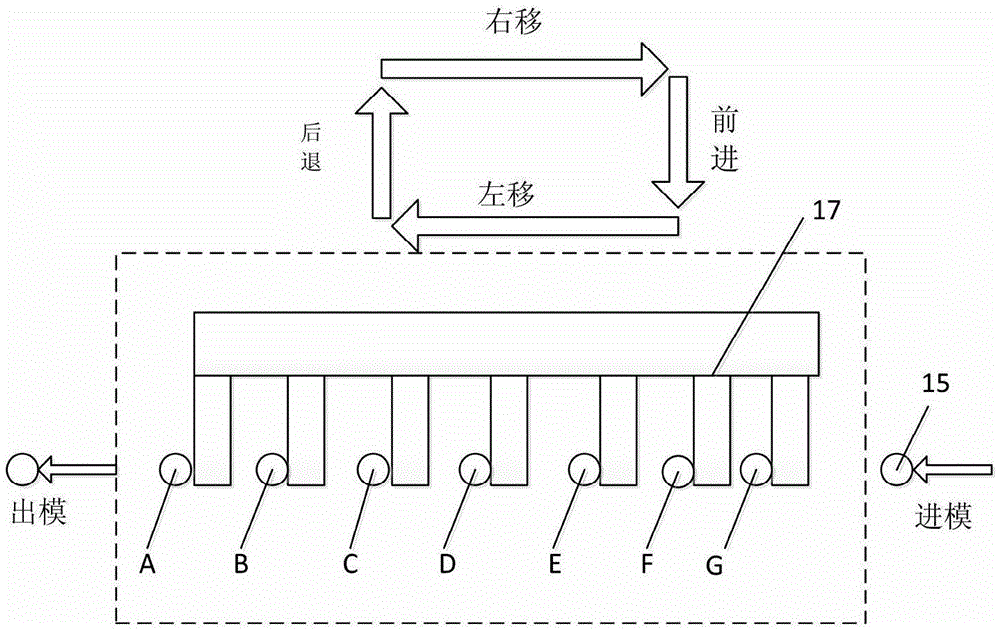

[0020] The multi-station precision molding process of the aspheric glass lens 18 is now described. First, the prefabricated glass blank is loaded into the mold 15, as figure 1 As shown, the mold 15 is then sent from the right plate 14 of the cavity to the low-temperature heating station, and the cylinder 12 of the low-temperature heating station driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com