Manufacturing method of 8-byte grating steel frame

The technology of grid steel frame and manufacturing method, which is applied in the field of grid steel frame production, can solve the problems that the grid steel frame cannot be realized, and achieve the effect of less manufacturing steps, high production efficiency and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

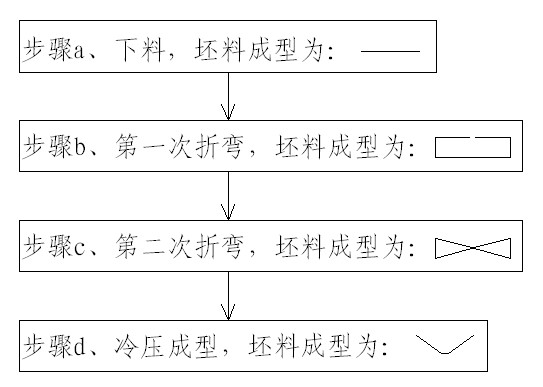

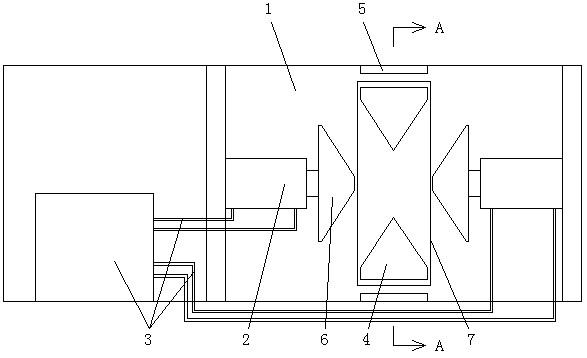

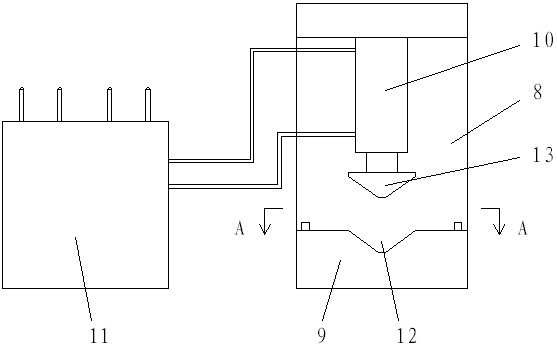

[0017] figure 1 It is the production flowchart of the production method of the 8-byte grid steel frame of the present invention; figure 2 It is a schematic diagram of the structure of the cold bending device; image 3 It is a schematic diagram of the structure of the cold pressing device.

[0018] As shown in the figure, the manufacturing method of the 8-byte grid steel frame in this embodiment includes the following steps:

[0019] a. Cutting the material, using a cutting machine to cut the steel bar into the specified size;

[0020] b. For the first bending, the steel bar is bent into a rectangular blank by a cold bending machine;

[0021] c. For the second cold bending, the rectangular blank is cold-finished by the cold bending device to complete the 8-byte grid blank;

[0022] d. Cold-press forming, the 8-byte grid blank is cold-pressed into a v-shape by a cold-pressing device.

[0023] The manufacturing method of the 8-byte grid steel frame has few manufacturing ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com