Resource utilization method of waste alkali liquid of viscose

A technology of viscose fiber and waste lye, applied in chemical instruments and methods, multi-stage water/sewage treatment, natural water treatment, etc., can solve the problems of less dosage of chemicals, hemicellulose fouling, and xylose recovery rate Low-level problems, to achieve the effect of promoting cooperation, high recovery rate, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

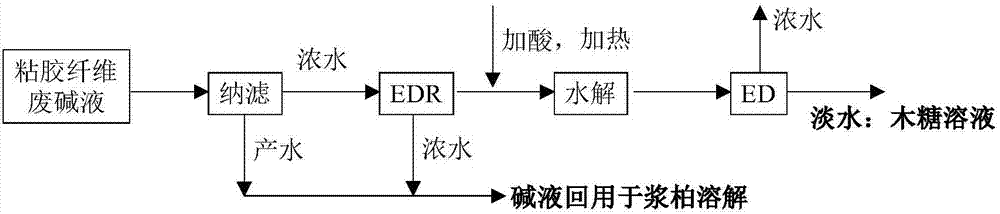

[0029] Refer to the attached figure 2 , First, according to the use of Dow alkali-resistant nanofiltration membrane, the molecular weight cut off is 200-1000, the viscose fiber waste alkali liquor is recovered, and the alkali liquor recovery rate is 60%. Then the mixed solution was dealkalized by EDR, and the final waste lye was dealkalized until the alkali content was 0.35wt%, the overall lye recovery rate and hemicellulose recovery rate could reach more than 97.5%, and no occurrence of fouling phenomenon.

[0030] Then, the pH of the mixed solution obtained after the above-mentioned dealkalization is adjusted with sulfuric acid, so that the pH of the mixed solution is 2, and the mixed solution is hydrolyzed at 150° C. for 30 minutes to obtain a fully hydrolyzed xylose solution. The hydrolyzed solution contains 1wt% sulfuric acid and 1 wt% sodium sulfate; then the hydrolyzed solution is desalted by ED, and desalted to conductivity=1ms / cm to obtain a xylose solution with a p...

Embodiment 2

[0035] Refer to the attached figure 2, First, according to the use of Dow alkali-resistant nanofiltration membrane, the molecular weight cut-off is 200-500, the alkali recovery of viscose fiber waste lye, the alkali recovery rate is 40%, and the mixture containing 12wt% hemicellulose and 12wt% NaOH is obtained. solution. Next, the mixed solution is dealkalized by EDR, and the final waste alkali liquor is dealkalized to an alkali content of 0.1 wt%, the overall alkali recovery rate and hemicellulose recovery rate can reach more than 99%, and no fouling phenomenon occurs.

[0036] Then, the pH of the above-mentioned dealkalized mixed solution is adjusted with sulfuric acid, so that the pH of the mixed solution is 4, and then the mixed solution is hydrolyzed at 160° C. for 20 min to obtain a fully hydrolyzed xylose solution. The hydrolyzed solution contains 0.5wt% of Sulfuric acid and 0.7 wt% sodium sulfate; then use ED to desalt the hydrolyzed solution to conduct conductivity=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com