Drying device for printing plate making of packaging bag

A drying device and packaging bag technology, applied in printing, printing plate preparation, etc., can solve problems such as uneven drying of layers, and achieve the effect of overcoming uneven drying

Active Publication Date: 2018-01-12

广德美好包装科技股份有限公司

View PDF6 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention aims at the above existing technical problems, and provides a drying device for packaging bag printing and plate making, so as to solve the problem of uneven drying of the layer when the existing oven dries the film blank

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the technical scheme of the present invention will be further described:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

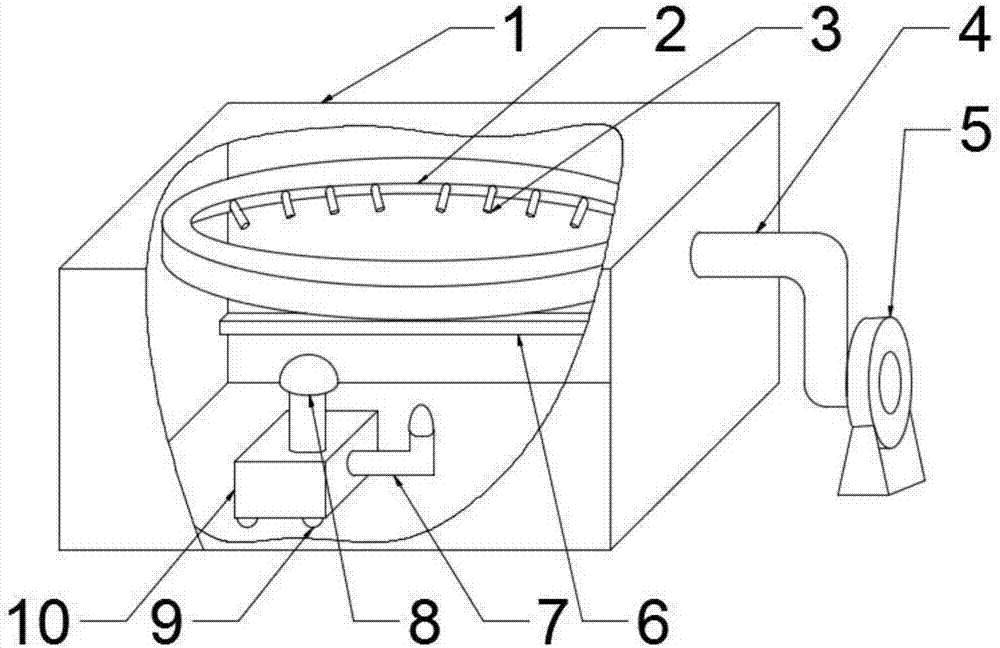

The invention discloses a drying device for printing plate making of a packaging bag in the field of printing equipment. The drying device comprises a box body and a heating mechanism, wherein articleplacing strips are arranged on two opposite side walls in the box body; the heating mechanism comprises a hot air heating assembly and a microwave heating assembly; the hot air heating assembly is located above the article placing strips; the hot air heating assembly comprises a vent pipe; the vent pipe communicates with an air inlet pipe and air outlet pipes; a heating wire is arranged in the air inlet pipe; one end, far away from the vent pipe, of the air inlet pipe penetrates through the box body and is connected with a fan; the multiple air outlet pipes are inclined obliquely below the inner side of the vent pipe; and the microwave heating assembly is located below the article placing strips. According to the drying device for the printing plate making of the packaging bag, hot air blowing is adopted above a film blank, and heating through the microwave penetration effect is adopted below the film blank; water starts evaporate from the inside of the object through heating, and water starts evaporate from the surface of the object through hot air blowing; in this way, through interior and exterior combination, a pattern layer painted inside a pattern is uniformly dried, and thetechnical problem that an existing drying box is not uniform in drying is solved.

Description

technical field [0001] The invention relates to the field of printing equipment, in particular to a drying device for printing and plate-making of packaging bags. Background technique [0002] Packaging bags are film containers used for packaging products. In order to meet the actual needs of sales, patterns are generally printed on packaging bags. The production process is planning, design, printing plate making, compounding, aging, cutting, bag making, product After inspection, the finished product is obtained. Among them, printing plate-making refers to making a graphic or text original into a printing plate, coating the plate with colorant printing ink, and transferring the colorant ink to paper or other substrates under pressure, and quickly copying in large quantities. craft. [0003] At present, the printed patterns on many food packaging bags are not strong in adhesion and stability, and they are easy to poke off after slight friction, resulting in incomplete patte...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B41C1/00

Inventor 张建平

Owner 广德美好包装科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com