Preparation technology of 6-series aluminum alloy friction stir welding member

A friction stir welding and friction stir technology, which is applied in the field of aluminum alloy components, can solve the problems of large strength loss of aluminum alloy materials, and achieve the effects of better mechanical properties, small strength loss and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

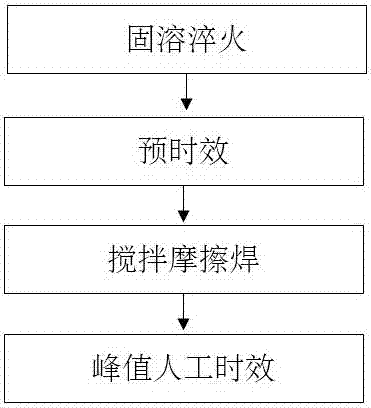

[0025] Please refer to figure 1 , the present embodiment provides a preparation process of a 6-series aluminum alloy friction stir welded component, comprising the following steps:

[0026] 1) On-line solution quenching: 4 mm thick, 6-series aluminum alloy profiles to be treated are subjected to on-line solution quenching.

[0027] Among them, the composition and mass percentage of the 6-series aluminum alloy are: Mg: 1.2%, Si: 1.2%, Mn: 1%, Fe: 0.8%, Cu: 0.8%, Cr: 0.4%, and contain one of the following: Or more than one element: Zn≤0.30%, Ti≤0.25%, V≤0.25%, Hf≤0.25%, Sc≤0.25%, Zr≤0.25%, and the rest are Al and unavoidable impurities.

[0028] The online solution quenching process parameters are as follows: the heat treatment temperature is 500°C, the cooling method is air cooling, and the cooling rate is 120°C / s.

[0029] 2) Pre-aging: pre-aging the 6-series aluminum alloy profiles after on-line solution quenching.

[0030] The aging temperature for pre-aging is 90°C, and ...

Embodiment 2

[0045] Please refer to figure 1 , the present embodiment provides a preparation process of a 6-series aluminum alloy friction stir welded component, comprising the following steps:

[0046] 1) Offline solution quenching: 5 mm thick, 6-series aluminum alloy profiles to be treated are subjected to offline solution quenching.

[0047] Among them, the composition and mass percentage of the 6 series aluminum alloy are: Mg: 1.5%, Si: 1.5%, Mn: 1.2%, Fe: 1%, Cu: 1.2%, Cr: 0.5%, and contain one of the following Or more than one element: Zn≤0.30%, Ti≤0.25%, V≤0.25%, Hf≤0.25%, Sc≤0.25%, Zr≤0.25%, and the rest are Al and unavoidable impurities.

[0048] Off-line solution quenching process parameters are: heat treatment temperature is 540°C, cooling method is air cooling, and cooling rate is 150°C / s.

[0049] 2) Pre-aging: pre-aging the 6-series aluminum alloy profiles after on-line solution quenching.

[0050] The aging temperature for pre-aging is 130°C, and the holding time is 1h. ...

Embodiment 3

[0057] Please refer to figure 1 , the present embodiment provides a preparation process of a 6-series aluminum alloy friction stir welded component, comprising the following steps:

[0058] 1) Off-line solution quenching: 6 mm thick, 6-series aluminum alloy profiles to be processed are subjected to off-line solution quenching.

[0059] Among them, the composition and mass percentage of the 6-series aluminum alloy are: Mg: 1%, Si: 1%, Mn: 0.8%, Fe: 6%, Cu: 0.8%, Cr: 0.3%, and contain one of the following: Or more than one element: Zn≤0.30%, Ti≤0.25%, V≤0.25%, Hf≤0.25%, Sc≤0.25%, Zr≤0.25%, and the rest are Al and unavoidable impurities.

[0060] The off-line solution quenching process parameters are as follows: heat treatment temperature is 480°C, cooling method is water cooling, and cooling rate is 150°C / s.

[0061] Stretch and straighten 6-series aluminum alloy profiles or plates with a stretch rate of 0.5%.

[0062] 2) Pre-aging: pre-aging the 6-series aluminum alloy profi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com