Device for purifying waste gas from kitchen wastes

A technology for waste gas purification and kitchen waste, which is applied in the direction of chemical instruments and methods, the use of liquid separation agents, and the separation of dispersed particles. It can solve the problems of low purification efficiency, single purified waste gas components, and inadequate treatment of composite waste gas. It is easy to manufacture , reduce adverse effects, and improve the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

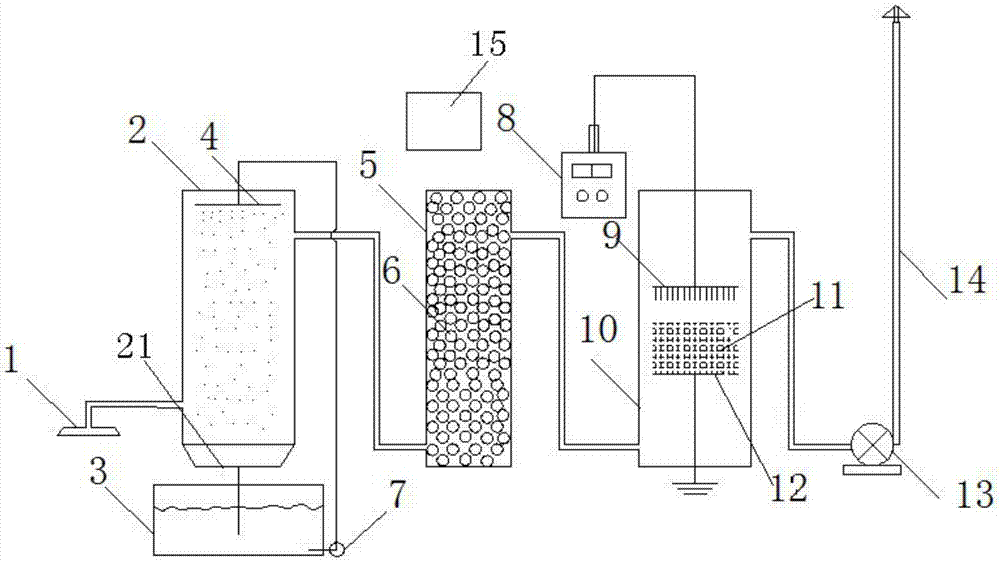

[0014] Embodiment 1: refer to figure 1 . A device for cleaning waste gas from food waste, comprising a gas collecting hood 1, an exhaust cylinder 14, an induced draft fan 13, a water circulation spray device, a drying device, a cooperative catalytic reaction device and a power supply device 15; the water circulation spray device It includes a spray tube 2, a water nozzle 4, a water storage tank 3 and a water pump 7. The top of the spray tube 2 is provided with a water nozzle 4, and the bottom of the spray tube 2 is a water outlet port 21, and the bottom of the water outlet port 21 is provided with The water storage tank tank 3 and the pumping port of the water pump 7 communicate with the water storage tank tank 3 through a pipe fitting, and the water outlet end communicates with the water nozzle 4 through a pipe fitting; the drying device includes a drying cylinder 5 and a desiccant 6, the drying cylinder 5 A desiccant 6 is provided inside; the high-voltage corona discharge s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com