Preparation method of medicinal controlled-release coating having pH response on surface of titanium implant

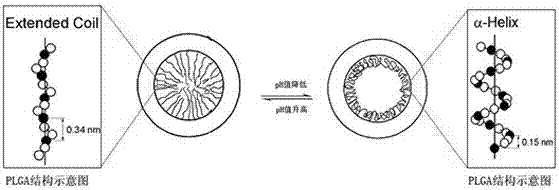

A technology of controlled drug release and titanium implants, applied in surface reaction electrolytic coatings, coatings, prostheses, etc., can solve the problem of inability to respond to local tissue inflammation, failure to achieve antibacterial effects, antibiotic-resistant strains, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

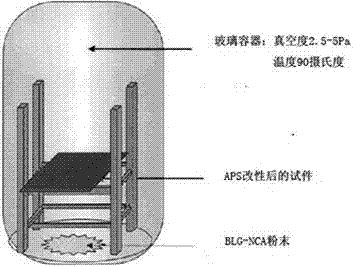

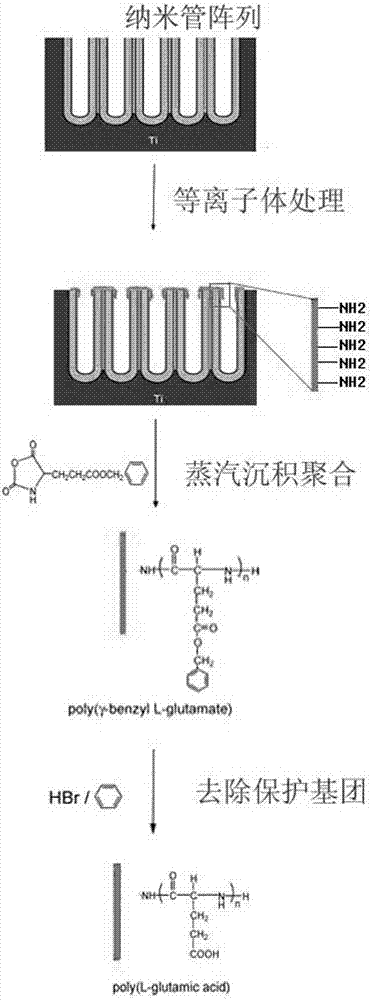

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Preparation of TiO on the surface of titanium material 2 nanotube:

[0029]a. Pretreatment of pure titanium sheet: firstly polish a 10mm×10mm×1mm pure titanium sheet with SiC sandpaper, and then ultrasonically clean it in acetone, ethanol, and deionized water for 2 minutes respectively. Processing 2min, described polishing fluid is made of HF, H 3 PO 4 and H 2 O is composed according to the volume ratio of 1:2:7. After polishing, it is washed with deionized water and dried naturally.

[0030] b. Preparation of organic electrolyte: NH 4 F and deionized water were added to 50 mL of glycerol to give NH 4 F mass concentration is 0.50wt%, and deionized water mass concentration is the glycerin solution of 10wt%;

[0031] c. A two-electrode system is adopted, with pure titanium sheet as the anode and platinum sheet as the cathode, and the distance between the electrodes is 1cm. Under magnetic stirring and 30°C, the DH1715A~5 DC stabilized voltage supply provides ...

Embodiment 2

[0037] Step 1. Preparation of TiO on the surface of titanium material 2 nanotube:

[0038] a. Pretreatment of pure titanium sheet: firstly polish a 10mm×10mm×1mm pure titanium sheet with SiC sandpaper, and then ultrasonically clean it in acetone, ethanol, and deionized water for 2 minutes respectively. Processing 2min, described polishing fluid is made of HF, H 3 PO 4 and H 2 O is composed according to the volume ratio of 1:2:7. After polishing, it is washed with deionized water and dried naturally.

[0039] b. Preparation of organic electrolyte: NH 4 F and deionized water were added to 60 mL of glycerol to give NH 4 F mass concentration is 0.60wt%, and deionized water mass concentration is the glycerin solution of 12wt%;

[0040] c. A two-electrode system is adopted, with pure titanium sheet as the anode and platinum sheet as the cathode, and the distance between the electrodes is 1cm. Under magnetic stirring and 30°C, the DH1715A~5 DC stabilized voltage supply provides...

Embodiment 3

[0046] Step 1. Preparation of TiO on the surface of titanium material 2 nanotube:

[0047] a. Pretreatment of pure titanium sheet: firstly polish a 10mm×10mm×1mm pure titanium sheet with SiC sandpaper, and then ultrasonically clean it in acetone, ethanol, and deionized water for 3 minutes respectively. Processing 3min, described polishing fluid is made of HF, H 3 PO 4 and H 2 O is composed according to the volume ratio of 1:2:7. After polishing, it is washed with deionized water and dried naturally.

[0048] b. Preparation of water-based electrolyte: dilute sulfamic acid with 50mL deionized water to prepare a solution with a mass percentage of 2%, then add hydrofluoric acid to the above solution to prepare a solution containing hydrofluoric acid with a mass percentage of 0.5% water-based electrolyte.

[0049] c. Preparation of organic electrolyte: NH 4 F and deionized water were added to 50 mL of glycerol to give NH 4 F mass concentration is 0.80wt%, and deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com