Preparation method of piezoelectric fiber composite material and piezoelectric fiber composite material

A technology of piezoelectric fiber composite and composite materials, which is applied in the preparation of piezoelectric fiber composite materials and the field of piezoelectric fiber composite materials, can solve the problem of reducing the flexibility and stability of composite materials, uneven polarization of piezoelectric fibers, and difficult issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of piezoelectric fiber composite material provided by the embodiment of the present invention, such as figure 1 Shown, the preparation method of this piezoelectric fiber composite material comprises:

[0048] S11: Alternately stacking piezoelectric thin layers and polymer thin layers, and coating polymer glue on adjacent surfaces to obtain a first laminated structure.

[0049] In this step, piezoelectric ceramics or piezoelectric single crystal thin layers can be prepared by cutting method or casting method to obtain piezoelectric thin layers with different thicknesses. The thermosetting resin can be prepared into polymer thin layers of different thicknesses by molding method, and the obtained polymer thin layer is cut to be consistent with the size of the piezoelectric thin layer, wherein the size includes length and width.

[0050] S12: curing the first laminated structure to obtain an unpolarized piezoelectric composite structure.

[00...

Embodiment 2

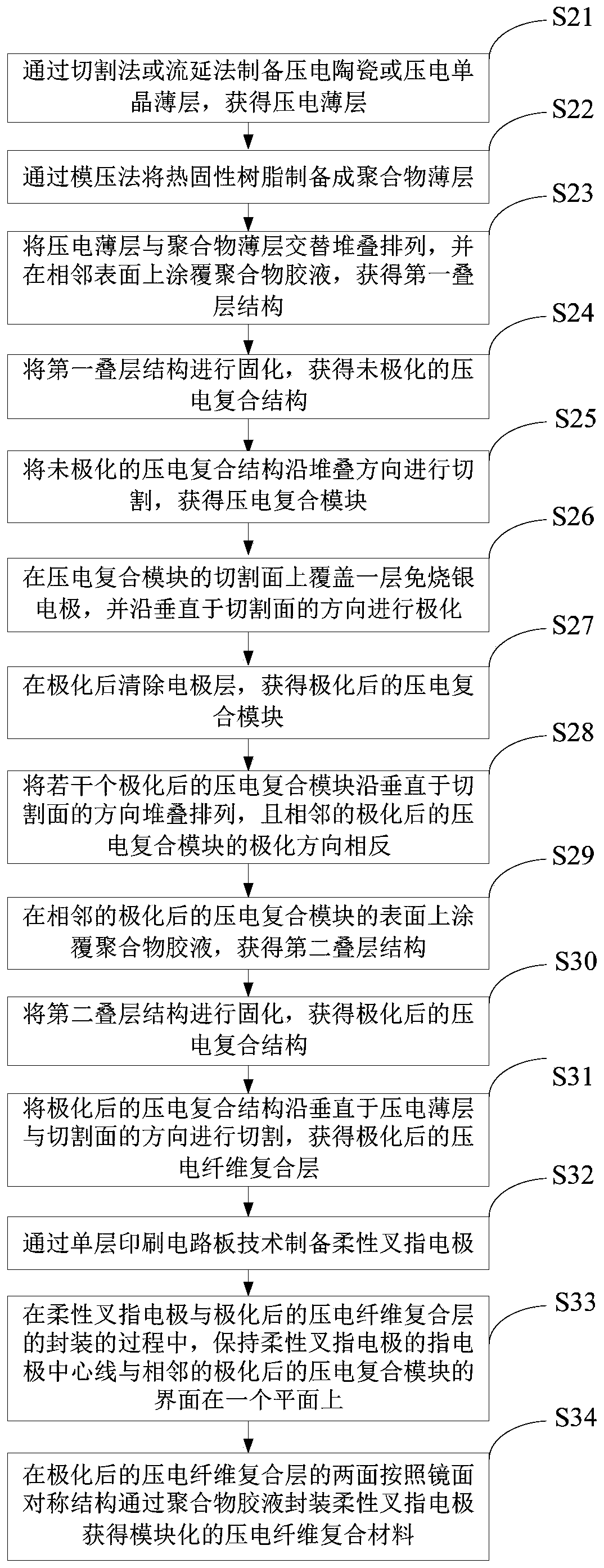

[0061] A kind of preparation method of piezoelectric fiber composite material provided by the embodiment of the present invention, such as figure 2 Shown, the preparation method of this piezoelectric fiber composite material comprises:

[0062] S21: Preparing piezoelectric ceramics or piezoelectric single crystal thin layers by cutting method or casting method to obtain piezoelectric thin layers.

[0063] In this step, if it is piezoelectric ceramics, lead zirconate titanate piezoelectric ceramics (Pb(Zr 1-x Ti x )O 3 , referred to as PZT) ceramic powder as the raw material, using the traditional solid-state method to prepare rectangular parallelepiped piezoelectric ceramics, the ceramic size is 50mm × 30mm × 20mm (length × width × height), the piezoelectric ceramics are cut into piezoelectric thin along the height direction layer, the size of the piezoelectric thin layer is 50mm×20mm×0.3mm (length×width×thickness), and the total number of piezoelectric thin layers can be ...

Embodiment 3

[0093] The embodiment of the present invention provides a piezoelectric fiber composite material, the piezoelectric fiber composite material can be made from the method for preparing the piezoelectric fiber composite material provided in the first or second embodiment above.

[0094] In this embodiment, PZT can be used as the piezoelectric phase, epoxy resin can be used as the polymer phase, and the piezoelectric fiber composite structure layer with gradient structure can be prepared by using the method for preparing the piezoelectric fiber composite material provided in the first or second embodiment above.

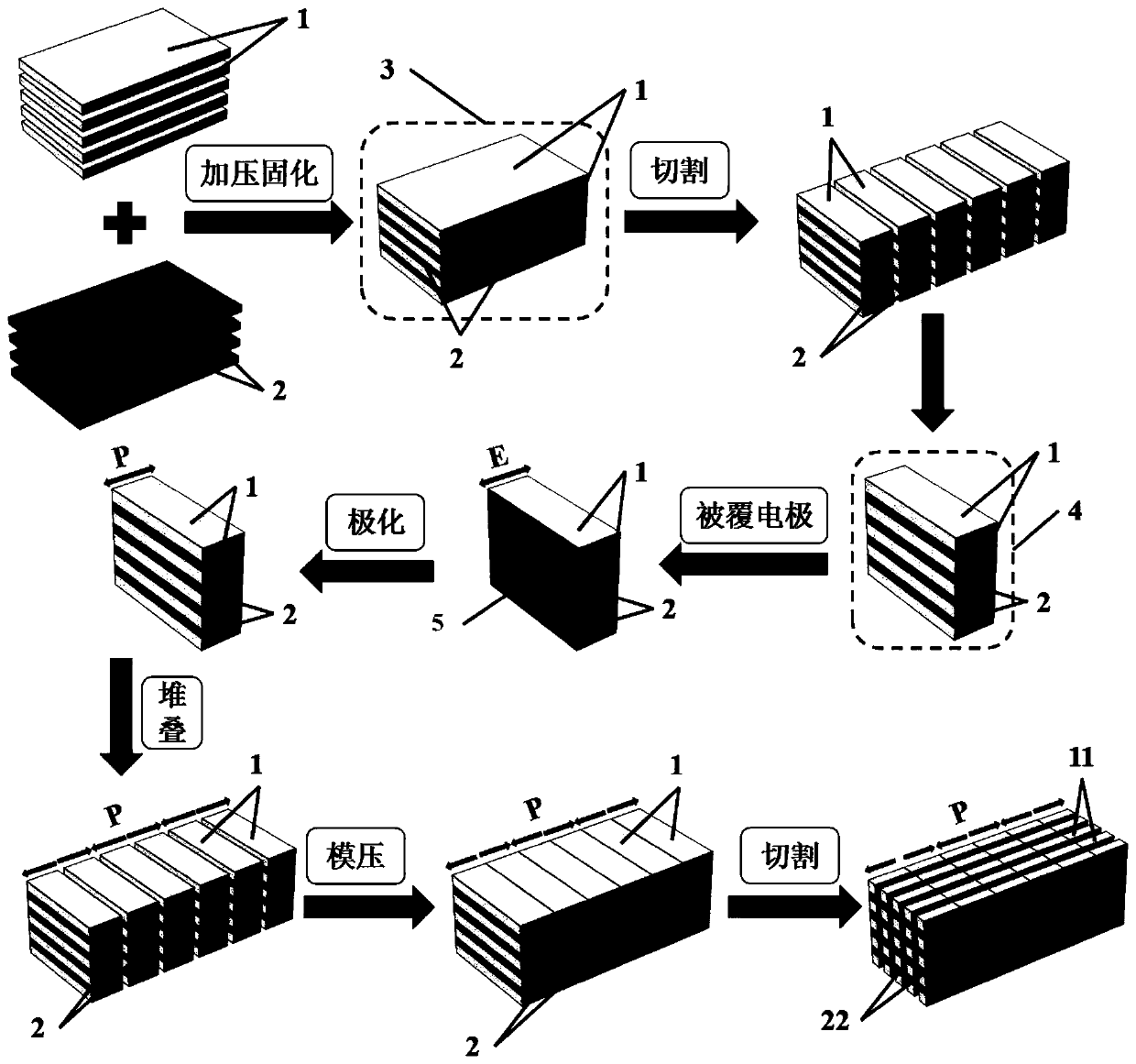

[0095] As another implementation of this example, the preparation method of the piezoelectric fiber composite material can also be according to image 3 way.

[0096] Such as image 3As shown, from top to bottom, the piezoelectric thin layer 1 and the polymer thin layer 2 are alternately stacked, and the outermost layer is controlled to be the piezoelectric thin layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com