CT data correction method and step test member

A data correction and test piece technology, applied in the field of medical imaging, can solve the problems of poor correction effect, lack of applicability, and affecting the quality of CT reconstruction images.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

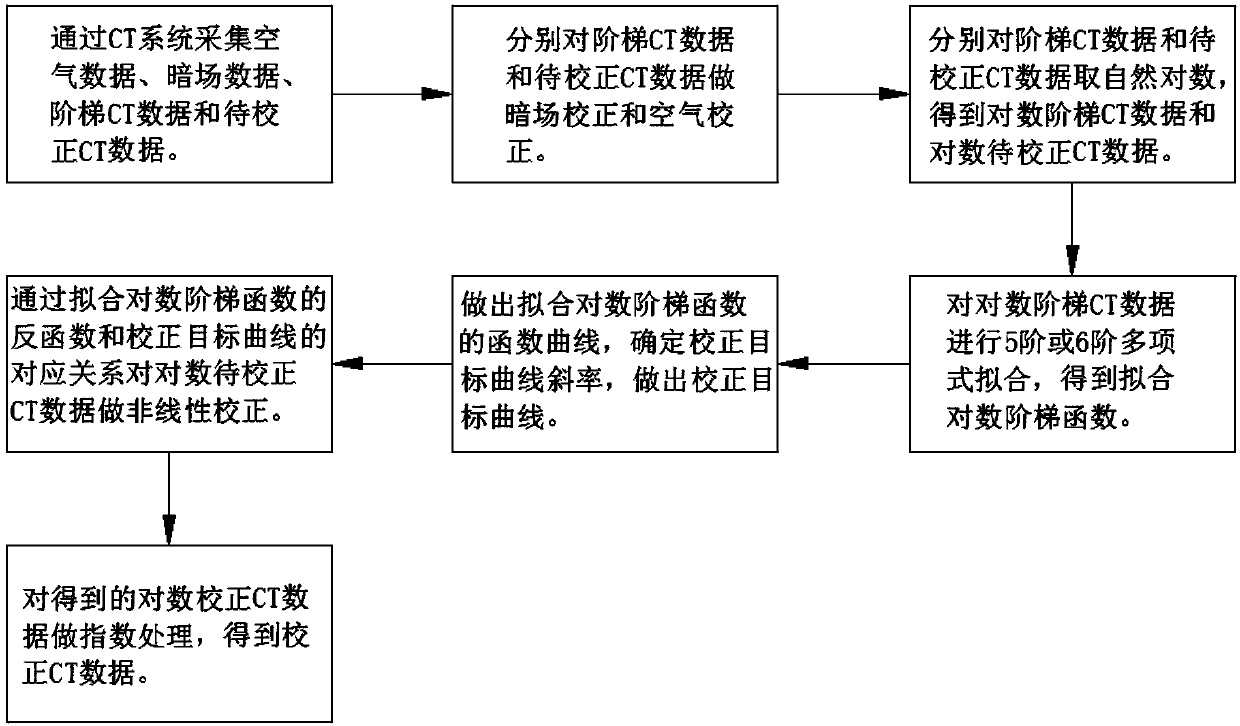

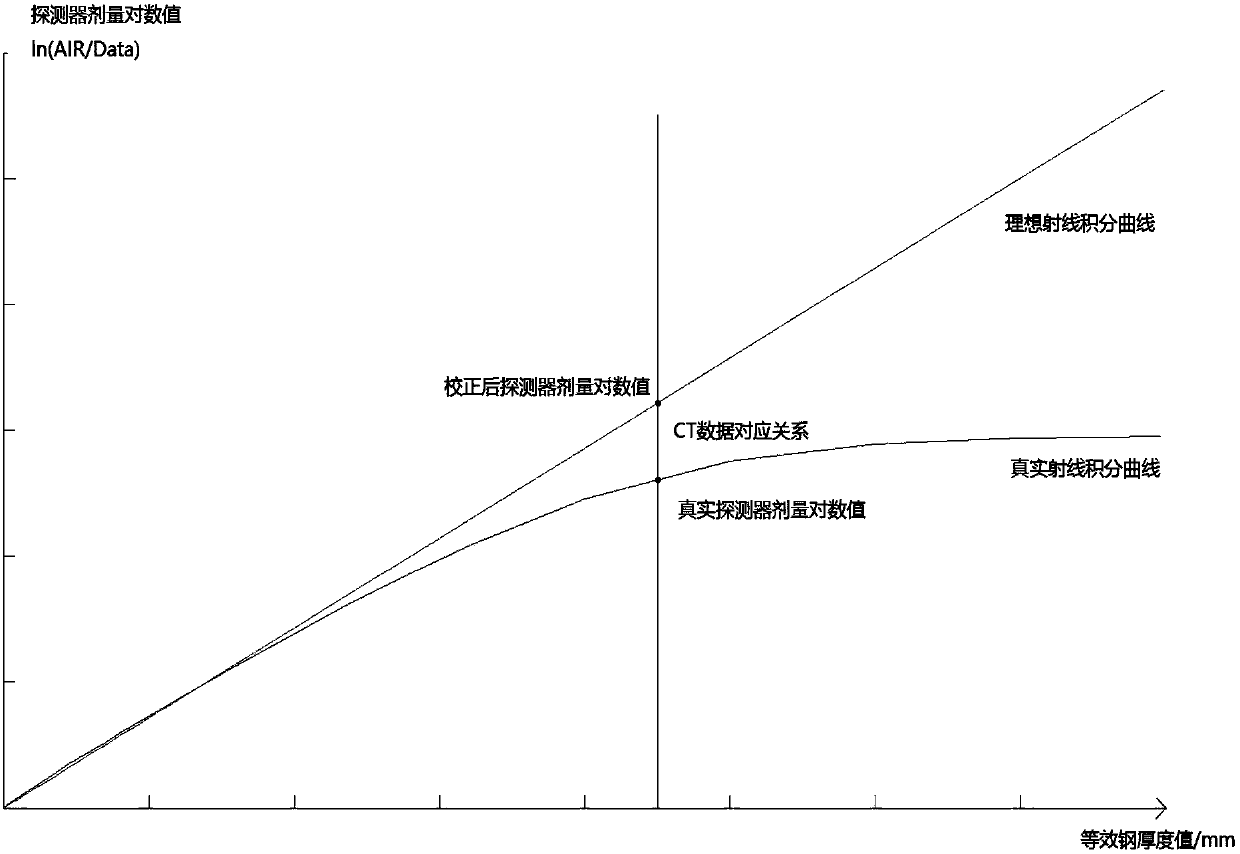

[0030] The specific content of the present invention will be described in detail below with reference to the drawings.

[0031] The invention discloses a CT data correction method, including dark field correction, air correction and CT data non-linear correction. The specific steps are as follows:

[0032] 1. Use CT system to collect dark field data and air data;

[0033] In the absence of X-rays, the dark-field data DARK(i) is collected by the detector of the CT system, where i represents the detector number. In the case of X-rays but no DUT, it is collected by the detector of the CT system Air data AIR(i), where i represents the detector number. Each detector unit corresponds to a dark field data and an air data. Therefore, the dark field data and the air data are two data sequences, as shown in the attached file. Figure 4 Shown.

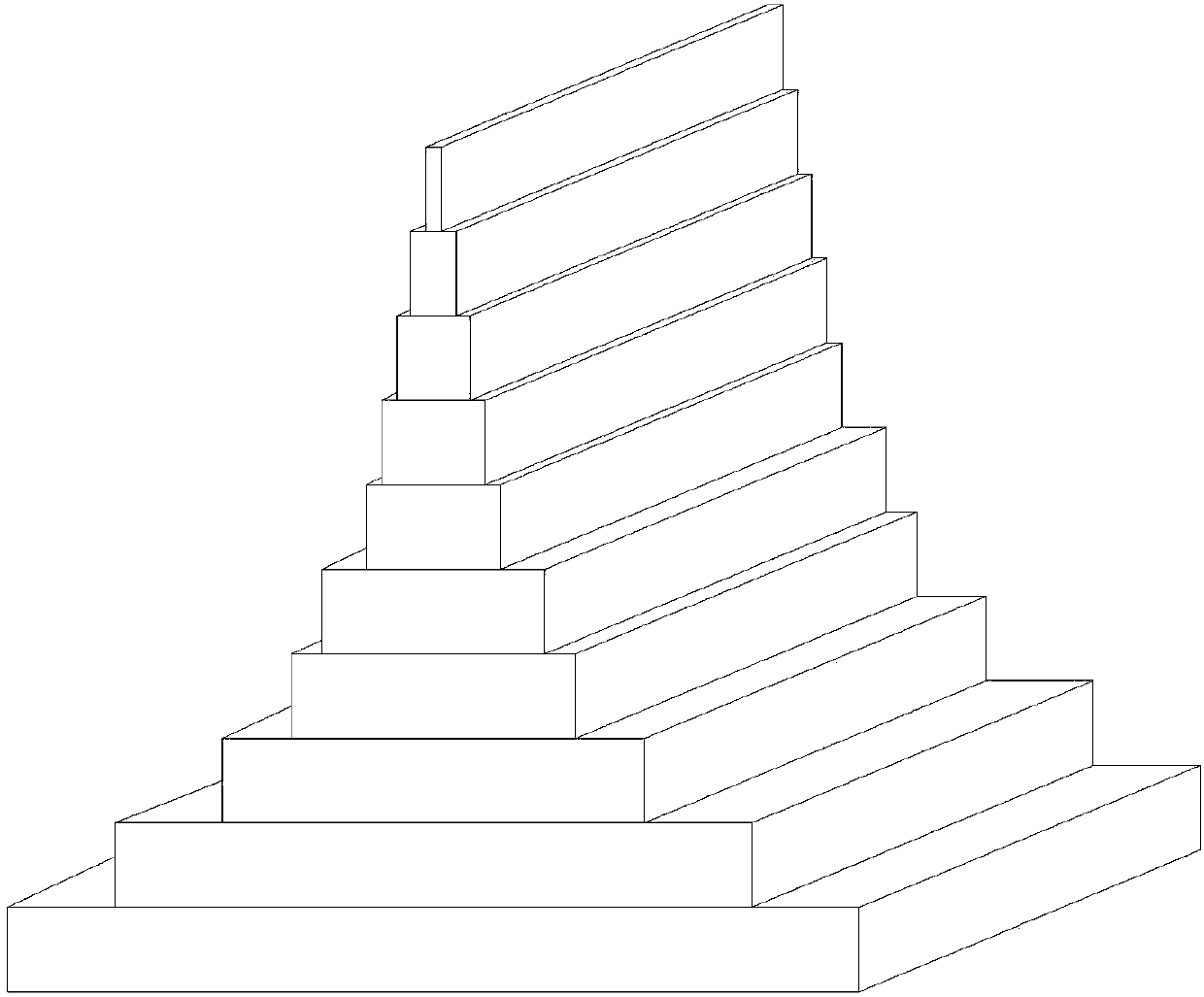

[0034] 2. Scan the ladder test piece with a CT system to collect ladder CT data;

[0035] Use X-rays to scan the ladder test piece layer by layer. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com